7

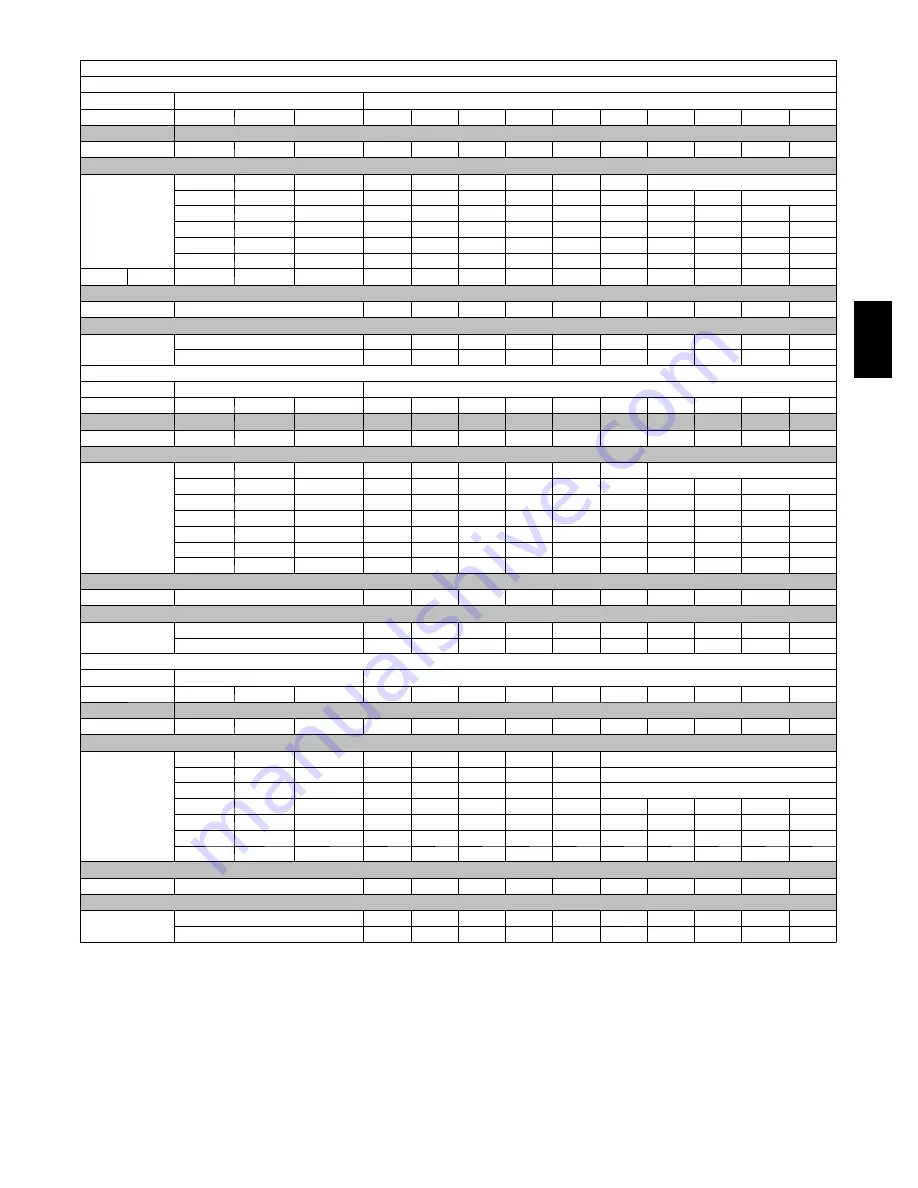

AIR DELIVERY -- CFM (CONTINUED)

COOLING

4

AND HEATING AIR DELIVERY - CFM (Bottom Return

5

With Filter)

(SW1-5 and SW4-3 set to OFF, except as indicated. See notes 1 and 2.)

Unit Size

Cooling Switch Settings

External Static Pressure (ESP)

SW2-3

SW2-2

SW2-1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

60080

Clg Default:

OFF

OFF

OFF

1905

1870

1825

1785

1750

1700

1665

1625

1560

1460

Cooling (SW2)

OFF

OFF

ON

950

770

620

515

440

365

See note 4

OFF

ON

OFF

1015

935

880

825

765

690

625

580

See note 4

OFF

ON

ON

1155

1105

1040

990

920

875

815

755

710

645

ON

OFF

OFF

1335

1290

1245

1190

1145

1085

1040

990

930

890

ON

OFF

ON

1520

1485

1435

1390

1340

1300

1255

1200

1160

1115

ON

ON

OFF

1905

1870

1825

1785

1750

1700

1665

1625

1560

1460

ON

ON

ON

2290

2230

2160

2085

2005

1915

1820

1730

1640

1525

Clg SW2:

Maximum Clg Airflow

2

2290

2230

2160

2085

2005

1915

1820

1730

1640

1525

Heating

(SW1)

High Heat Airflow

3

1575

1535

1485

1445

1400

1350

1310

1260

1215

1170

Low Heat Airflow

3

1230

1170

1125

1065

1015

955

900

855

795

755

Unit Size

Cooling Switch Settings

External Static Pressure (ESP)

SW2-3

SW2-2

SW2-1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

60100

Clg Default:

OFF

OFF

OFF

1890

1845

1800

1755

1700

1655

1610

1560

1510

1460

Cooling (SW2)

OFF

OFF

ON

1015

825

630

485

405

325

See note 4

OFF

ON

OFF

1080

895

815

740

690

615

555

475

See note 4

OFF

ON

ON

1155

1080

1020

940

890

825

785

710

660

590

ON

OFF

OFF

1310

1260

1195

1140

1075

1025

970

925

875

810

ON

OFF

ON

1520

1475

1425

1365

1315

1255

1210

1155

1110

1055

ON

ON

OFF

1890

1845

1800

1755

1700

1655

1610

1560

1510

1460

ON

ON

ON

2290

2230

2160

2085

2005

1915

1820

1730

1640

1525

Clg SW2:

Maximum Clg Airflow

2

2290

2230

2160

2085

2005

1915

1820

1730

1640

1525

Heating

(SW1)

High Heat Airflow

3

1905

1865

1825

1775

1730

1685

1640

1590

1545

1490

Low Heat Airflow

3

1480

1435

1375

1330

1265

1215

1160

1115

1060

1005

Unit Size

Cooling Switch Settings

External Static Pressure (ESP)

SW2-3

SW2-2

SW2-1

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

0.9

1.0

66120

6

Clg Default:

OFF

OFF

OFF

2010

1960

1910

1850

1800

1750

1690

1645

1565

1480

Cooling (SW2)

OFF

OFF

ON

1015

805

645

550

480

See note 4

OFF

ON

OFF

1075

975

915

835

765

See note 4

OFF

ON

ON

1205

1135

1055

1000

935

See note 4

ON

OFF

OFF

1400

1330

1260

1190

1145

1080

1035

970

905

845

ON

OFF

ON

1615

1550

1500

1435

1370

1325

1265

1215

1160

1110

ON

ON

OFF

2010

1960

1910

1850

1800

1750

1690

1645

1565

1480

ON

ON

ON

note 8

2375

2300

2205

2115

2010

1890

1750

1645

1550

Clg SW2:

Maximum Clg Airflow

2

note 8

2375

2300

2205

2115

2010

1890

1750

1645

1550

Heating

(SW1)

High Heat Airflow

3

note 8

2375

2300

2205

2115

2010

1890

1750

1645

1550

Low Heat Airflow

3

1735

1675

1625

1560

1500

1455

1395

1345

1285

1225

1. Nominal 350 CFM/ton cooling airflow is delivered with SW1-5 and SW4-3 set to OFF.

Set both SW1-5 and SW4-3 to ON for +7% airflow (nominal 370 CFM/ton).

Set SW1-5 to ON and SW4-3 to OFF for +15% airflow (nominal 400 CFM/ton).

Set SW4-3 to ON and SW1-5 to OFF for -7% airflow (nominal 325 CFM/ton).

The above adjustments in airflow are subject to motor horsepower range/capacity.

2. Maximum cooling airflow is achieved when switches SW2-1, SW2-2, SW2-3 and SW1-5 are set to ON, and SW4-3 is set to OFF.

3.

All heating CFM's are when low heat rise adjustment switch (SW1-3) and comfort/efficiency adjustment switch (SW1-4) are both set to OFF.

4.

Ductwork must be sized for high-heating CFM within the operational range of E.S.P. Operation within the blank areas of the chart is not recommended

because high-heat operation will be above 1.0 E.S.P.

5. All airflows of 1800 CFM or less on 21” and 24.5” casing size furnaces are 5% less on side return only installations.

6. Airflows over 1800 CFM require bottom return, two-side return, or bottom and side return. A minimum filter size of 20” x 25” is required.

7. For upflow applications, air entering from one side into both the side of the furnace and a return air base counts as a side and bottom return.

8.

Airflow not stable at this E.S.P.

PG96V

A

T