63

START--UP, ADJUSTMENT, AND SAFETY

CHECK

Important Installation and Start--up Procedures

Failure to follow this procedure may result in a nuisance

smoke or odor complaint.

The manifold pressure, gas rate by meter clocking,

temperature rise and operation must be checked after

installation.

Minor smoke and odor may be present

temporarily after start--up from the manufacturing process.

Some occupants are more sensitive to this minor smoke and

odor. It is recommended that doors and windows be open

during the first heat cycle.

NOTICE

General

1. Furnace must have a 115-v power supply properly connect-

ed and grounded.

NOTE

: Proper polarity must be maintained for 115-v wiring.

Control status indicator light flashes rapidly and furnace does not

operate if polarity is incorrect of if the furnace is not grounded.

2. Thermostat wire connections at terminals R, W/W1, G, and

Y/Y2 must be made at 24-v terminal block on furnace con-

trol.

3. Natural gas service pressure must not exceed 0.5 psig (14-

in. w.c., 350 Pa), but must be no less than 0.16 psig (4.5-in.

w.c., 1125 Pa).

4. Blower door must be in place to complete 115-v electrical

circuit and supply power to the furnace components.

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance dissatisfaction.

These furnaces are equipped with a manual reset limit

switch in burner assembly. This switch opens and shuts off

power to the gas valve if an overheat condition (flame

rollout) occurs in the burner assembly/enclosure. Correct

inadequate combustion--air supply, improper gas pressure

setting, improper burner or gas orifice positioning, or

improper venting condition before resetting switch. DO

NOT jumper this switch.

CAUTION

!

Before operating furnace, check flame rollout manual reset switch

for continuity. If necessary, press button to reset switch.

EAC-1 terminal is energized whenever blower operates. HUM

terminal is only energized when the gas valve is energized in

heating.

Thermostat Setup Switch

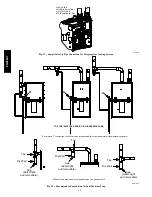

This furnace can be installed with either a single--stage heating or a

2--stage heating thermostat. Setup switch SW--1 (LHT) is used to

configure the furnace for single or two stage thermostat operation.

For single--stage thermostats, connect thermostat W to W/W1 at

furnace control terminal block. See Fig. 37. For single--stage

thermostats, the control will determine, based on length of previous

heating on and off cycles, when to operate in low-- and high--gas

heat for optimum comfort. Setup switch SW--1 (LHT) must be in

the factory--shipped OFF position. See Fig. 37 and 71 for setup

switch information.

If a 2--stage heating thermostat is to be used, move SW--1 (LHT) to

ON position before starting furnace. This overrides built--in control

process for selecting high and low fire and allows the 2--stage

thermostat to select gas heating modes. The W2 from thermostat

must be connected to W2 on control terminal block.

Prime Condensate Trap with Water

CARBON MONOXIDE POISONING HAZARD

Failure to follow these warnings could result in personal injury

or death.

Failure to use a properly configured trap or NOT

water--priming trap before operating furnace may allow

positive pressure vent gases to enter the structure through drain

tube. Vent gases contain carbon monoxide which is tasteless

and odorless.

!

WARNING

UNIT OPERATION HAZARD

Failure to follow this caution may result in intermittent unit

operation or performance satisfaction.

Condensate trap must be PRIMED or proper draining may

not occur. The condensate trap has two internal chambers

which can ONLY be primed by pouring water into the

inducer drain side of condensate trap.

CAUTION

!

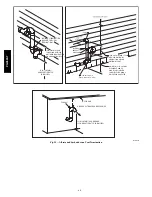

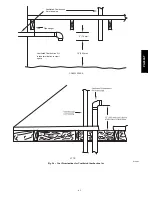

1. Remove upper and middle collector box drain plugs oppo-

site of the condensate trap. See Fig. 66.

2. Connect field-supplied 5/8-in. (16 mm) ID tube with at-

tached funnel to upper collector box drain connection. See

Fig. 66.

3. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate trap,

and flow into open field drain.

4. Remove funnel; replace collector box drain plug.

5. Connect field-supplied 5/8-in. (16 mm) ID tube to middle

collector box drain port.

6. Pour one quart (liter) of water into funnel/tube. Water

should run through collector box, overfill condensate trap,

and flow into open field drain.

7. Remove funnel and tube from collector box and replace col-

lector box drain plug.

Purge Gas Lines

If not previously done, purge the lines after all connections have

been made and check for leaks.

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Never purge a gas line into a combustion chamber. Never

test for gas leaks with an open flame. Use a commercially

available soap solution made specifically for the detection

of leaks to check all connections. A fire or explosion may

result causing property damage, personal injury or loss of

life.

!

WARNING

PG95X

AT