35

Changing Orifices for High Altitude

ELECTRICAL

SHOCK,

FIRE

OR

EXPLOSION

HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Turn OFF electric power (at disconnect) and gas supply (at

manual valve in gas line) when installing orifices. Installation

of orifices requires a qualified service technician.

!

WARNING

NOTE

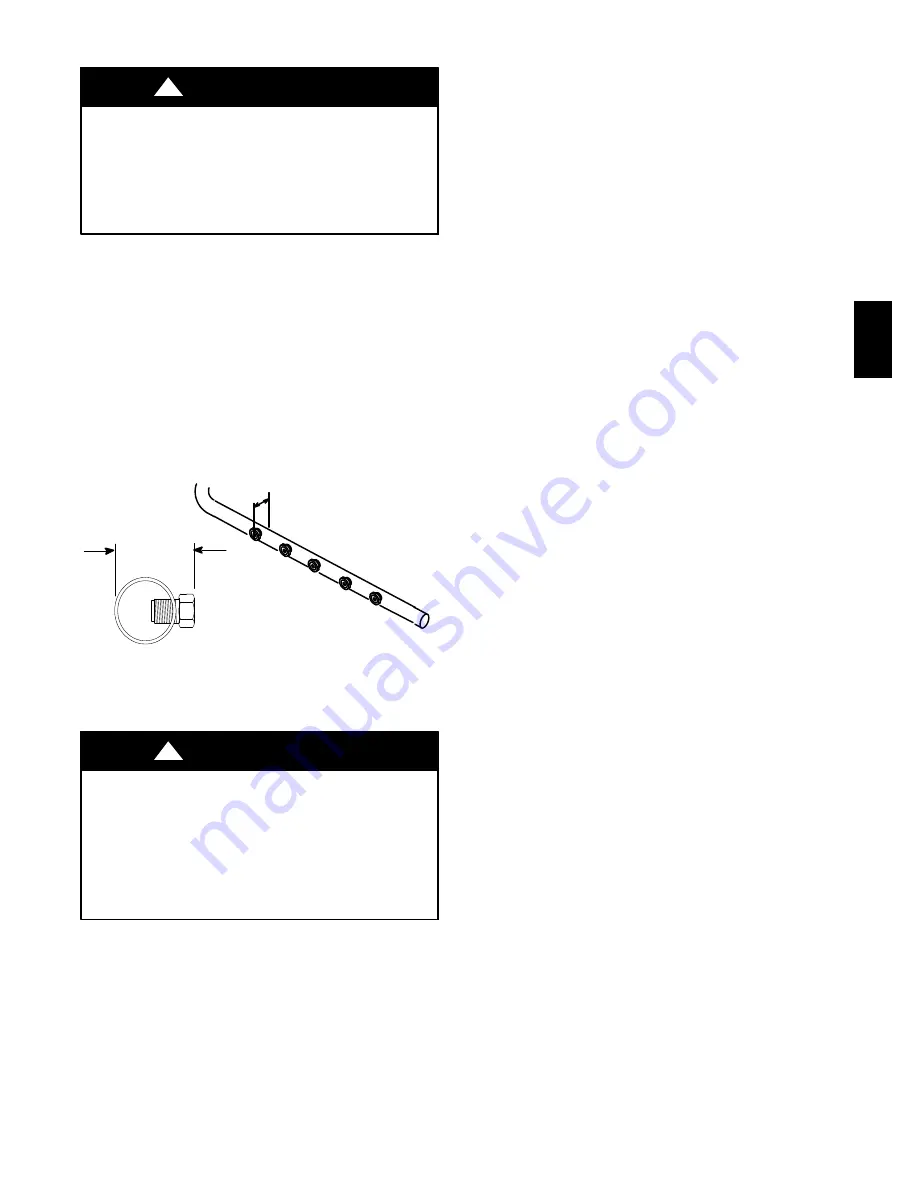

: Main burner orifices can be changed for high altitudes.

1. Disconnect gas line from gas valve.

2. Remove manifold from furnace.

3. Remove the orifices from the manifold and replace them

with properly sized orifices.

4. Tighten orifices so it is seated and gas tight. (See Fig. 35)

5. Reinstall manifold. Ensure burners do

NOT

bind on new

orifices.

Natural Gas Input Rating Check

SEE CHECKS AND ADJUSTMENTS, Natural Gas Input

Rating Check

in this manual.

Measure from face of orifice

to the back side of the

manifold.

1.11

″

(28.2mm)

1.21

″

(30.8mm)

A07725

Fig. 35 -- Changing Orifices

Final Gas Piping Check

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

Never test for gas leaks with an open flame.

Use a

commercially available soap solution made specifically for the

detection of leaks to check all connections.

A fire or

explosion could result causing property damage, personal

injury and/or loss of life.

!

WARNING

1. The furnace and the equipment shut off valve must be dis-

connected from the gas supply piping system during any

pressure testing of that system at test pressures in excess of

1

/

2

″

PSIG. Close the manual shut--off valve before testing

at such pressures.

2. When installation is complete, test all pipe connections for

leaks with the gas pressure less than

1

/

2

″

PSIG to the gas

valve.

3. The furnace must be isolated from the gas supply system

by closing the equipment shut off valve during any pres-

sure testing of the gas supply system at test pressure equal

to or less than

1

/

2

″

PSI (3.5 kPa).

4. Apply a commercial soap solution to all joints to test for

leaks. Correct any leaks indicated by bubbles.

5. Correct even the smallest leak at once.

6. Check for leaks at gas valve and orifice connections to the

burner manifold while the furnace is operating.

ELECTRICAL WIRING

Power Supply Wiring

The furnace

MUST

be electrically wired and grounded in

accordance with local codes, or in the absence of local codes with

the latest edition of The National Electric Code, ANSI NFPA 70

and/or The Canadian Electric Code CSA C22.1.

The power supply to the furnace connections must be between

104 VAC and 127 VAC during furnace operation for acceptable

performance.

Field wiring connections must be made inside the furnace

connection box. A suitable strain relief should be used at the

point the wires exit the furnace casing.

Copper conductors shall be used.

Line voltage wires should

conform to temperature limitation of 63

°

F (35

°

C) rise and be

sized for the unit maximum amps stated on the rating plate. Add

the full load amps for potential field--installed accessories such as

electronic air cleaners and humidifiers that would receive power

from the furnace control. The furnace control is rated for a

maximum of 1.0 amp combined for EAC and HUM. Consult

NEC or local codes for proper wire and circuit sizing.

NOTE

: Furnace will not have normal operation if line polarity is

reversed. Check ALL field and control connections prior to

operation.

Junction Box (J- Box) Relocation

The J--box is installed on left side of casing. An alternate j--box

location on right side can be used.

1. Remove bag containing two hole plugs and two self tap-

ping screws from loose parts bag in blower compartment.

2. Remove two screws holding J--Box to casing.

3. Move large hole plug from right to left J--Box location.

4. Clip wire tie holding J--Box wires.

5. Move J--Box to alternate location and attach using two self

tapping screws from bag.

6. Apply two hole plugs from bag at left J--Box location.

Thermostat

Thermostat location has an important effect on the operation of

the unit. Follow instructions included with thermostat for correct

mounting and wiring.

Low voltage connections to furnace must be made on terminal

board of furnace control.

Heat anticipator setting will need to be measured if 24VAC

humidifier is installed. Measure current in series from R to W at

the thermostat. Be sure 24VAC humidifier is wired up to control.

Allow furnace to operate for 2 minutes before recording the AC

amperage reading. Set anticipator on thermostat to recorded

value.

PG9Y

AA