36

Optional Equipment

All wiring from furnace to optional equipment

MUST

conform to

local codes or, in the absence of local codes with the latest edition

of The National Electric Code, ANSI NFPA 70 and/or The

Canadian Electric Code CSA C22.1. Install wiring in accordance

with manufacturer’s instructions. The wiring

MUST

have a

minimum temperature rating of 105

°

C.

Humidifier/Electronic Air Cleaner

The furnace is wired for humidifier and/or electronic air cleaner

connection.

REDUCED FURNACE LIFE HAZARD

Failure to follow this caution may result in reduced furnace

life.

Do NOT exceed 115V/1.0 amp. maximum current load for

both the EAC terminal and the HUM terminal combined.

CAUTION

!

HUMIDIFIER -- The HUM (115) is energized when the pressure

switch closes on a call for heat. The HUM is energized when the

inducer is energized.

ELECTRONIC AIR CLEANER -- EAC is energized when there

is a blower speed call, except is NOT energized when blower

operates in the hard--wired continuous fan mode.

Furnace Control

The furnace control is preset at the factory with a fixed blower

ON

delay of 30 seconds in the heating mode. The blower

OFF

timing is preset at 140 seconds. If desired, the fan

OFF

delay can

be reset to obtain the longest delay times while still maintaining

comfort levels. See “Furnace Wiring Diagram” .

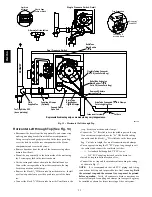

NOTE: Junction Box can be

mounted to either the left or right

side.

Models may

have 1 or 2

pressure

switches

NOTE: 115 VAC/60Hz/single--phase

Operating voltage range*: 127 VAC max, 104 VAC min.

* Permissible limits of voltage at which unit will operate satisfactorily

115V. 60 Hz

W

W

W

Low Voltage

Terminal Board

R

R

BK

Ground

Connection

Box

G

HO

T

NEUT

.

G

G

Y

G

O

N

O

FF

Representative drawing only, some models may vary in appearance.

A07726

Fig. 36 -- Electrical Connections

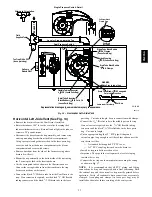

Furnace Control Fuse

The 24V circuit contains a 5--amp, automotive--type fuse located

on furnace control. (See Fig. 37) Any electrical shorts of 24V

wiring during installation, service, or maintenance may cause

fuse to blow. If fuse replacement is required, use only a fuse of

identical size (5 amp.)

Blower Off

Delay Jumper

FUSE

Diagnostic Light

24 VAC

HUM

115 VAC

HUM

EAC

A07727

Fig. 37 -- Control Board

DUCTWORK AND FILTER

CARBON MONOXIDE POISONING HAZARD

Failure to follow this warning could result in personal injury or

death.

Do NOT draw return air from inside a closet or utility room

where furnace is located. Return air duct MUST be sealed to

furnace casing.

!

WARNING

Installation

NOTE

: Design and install the air distribution system to comply

with Air Conditioning Contractors of America manuals and/or

NFPA pamphlets 90A and 90B or other approved methods that

conform to local codes and good trade practices.

1. When furnace supply ducts carry air outside furnace area,

seal return air duct to furnace casing and terminate duct

outside furnace space.

2. Install air conditioning cooling coil (evaporator) on outlet

side of furnace.

3. For furnaces installed without a cooling coil it is recom-

mended that the outlet duct be provided with a removable

access panel. This panel should be accessible when the

furnace is installed so the exterior of the heat exchanger

can be viewed for inspections. The access panel

MUST

be

sealed to prevent leaks.

4. If separate evaporator and blower units are used, install

good sealing dampers for air flow control. Chilled air go-

ing through the furnace could cause condensation and

shorten the furnace life.

NOTE

: Dampers (field supplied) can be either automatic or

manual. Manually operated dampers

MUST

be equipped with a

means to prevent furnace or air conditioning operation unless

damper is in the full heat or cool position.

PG9Y

AA