11

Winterizing your Sprayer

It is essential that you winterize your sprayer to avoid damage and to allow for optimal performance. The winterization process

should be undertaken before freezing conditions and/or after each season of use. Failure to winterize your sprayer will void the

manufacturer’s warranty.

Note: Please reference your sprayer owners manual for proper winterizing.

Maintenance Instructions

Routine Maintenance

1. It is recommended to perform a visual and physical inspection for worn parts, loose bolts, damaged hoses, or other visible

problems. Make all necessary repairs before spraying. To order parts or receive technical help, please contact the original

retailer.

2. After each use it is important to rinse the boom and all components by running water through the entire system.

3. Tip strainers should be taken out and rinsed on a regular basis. Tip strainers are the small screens located behind each spray

nozzle on the boom (Figure 6, page 6).

4. Check the amount of grease between the hinge plate and the boom wing. Add grease as needed to keep the wing folding

smoothly and quietly.

It is very important to perform routine maintenance on your sprayer boom before and after each use. Good maintenance practices

will help to guard against any breakdowns or accidents.

Note: Always wear the proper Personal Protective Equipment (PPE) when performing maintenance on your sprayer.

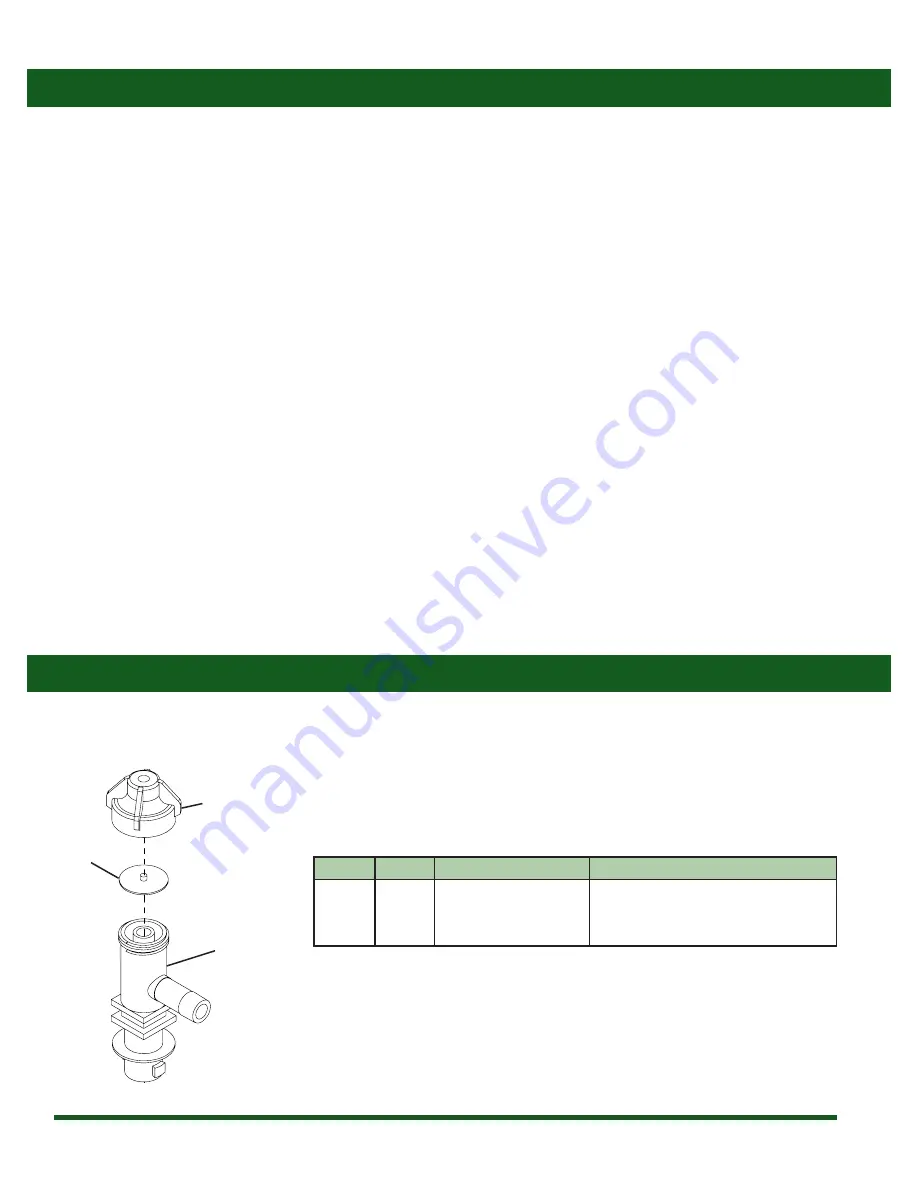

TeeJet

®

Nozzle Body Breakdown & Parts List

Breakdowns & Parts Lists

Ref #

Qty.

Part Number

Description

1

1

22251311500NYB

Elbow body, 1/2” (shown)

-

1

22252312500NYB

Tee body, 1/2”

2

1

CP21953EPR*

Rubber diaphragm

3

1

2195010NYB*

Diaphragm cap, 10 psi

3

1

2

Note: Items 2 & 3 are included with Item 1