5

a

b

c

e

Discharge Tubes

Discharge Hose

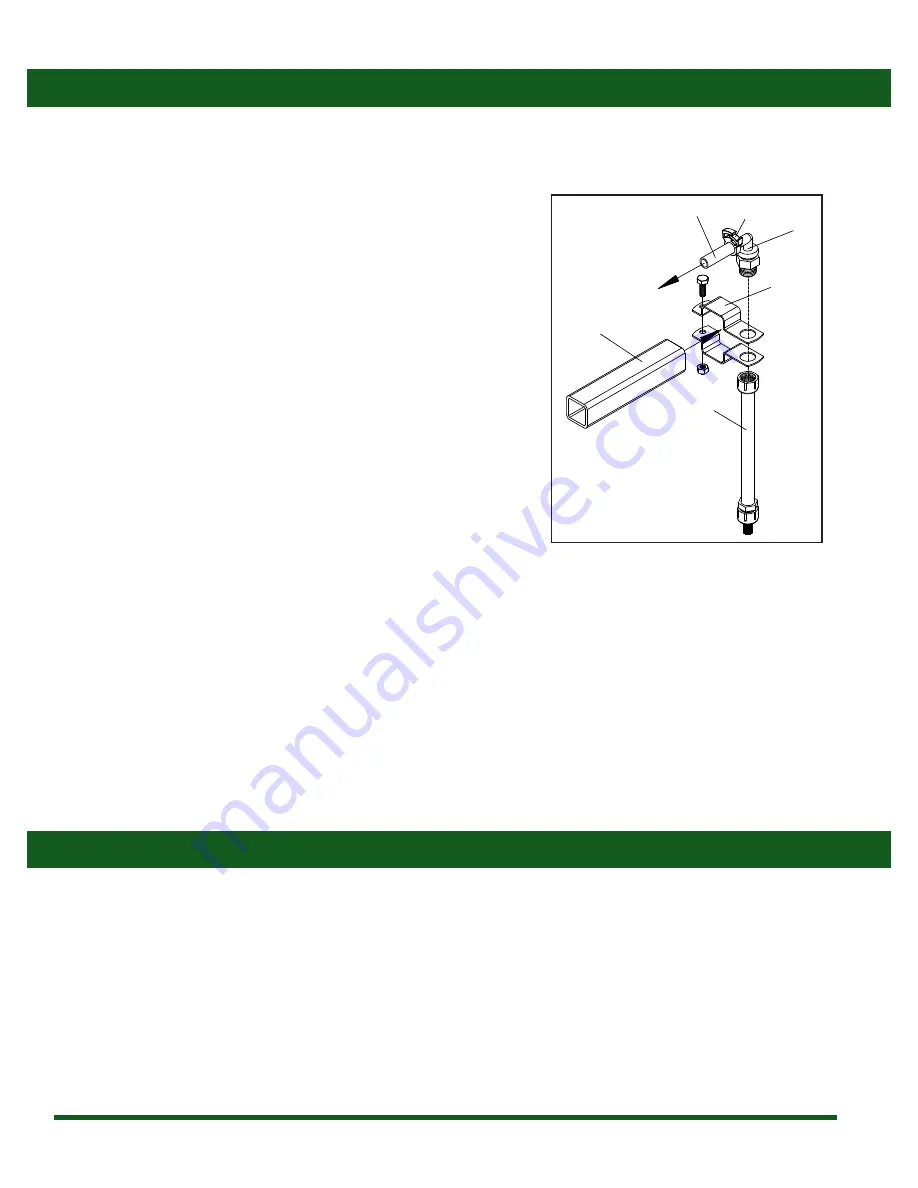

1. The discharge tubes (a) dispense the foam and should

be mounted in the desired foaming position.

Generally, they are mounted at the end of a sprayer

boom (b) (Figure 4).

2. If you are mounting the tubes on a sprayer, a nozzle body

clamp (c) can be used. Simply mount the clamp on the

sprayer's boom and insert the threaded barb elbow (d)

through the hole where the nozzle body would normally

go.

3. Ensure that the discharge tube does not interfere with

the operation of the equipment it is mounted on. For

example, make sure that the discharge tubes do not

interfere with the spray pattern if you are mounting the

foam marker on a sprayer.

1. One 33’ length of 3/8” discharge hose is included with the

turf foam marker and may be cut as needed.

2. Begin by attaching the discharge (e) hose to the hose

barbs on the compressor on the foam marker unit.

3. It is important that both hoses are the same length. This

will ensure uniform foaming from both discharge tubes.

Clamp the hose onto the hose barbs with the included

hose clamps (f).

4. Route the discharge hoses (e) to the discharge tubes and

attach the hose to the threaded barb elbow (d) (Figure 4).

Figure 4: Discharge Tube Mounting

Operating Instructions

Before operating the turf foam marker, it is important that you read this entire manual and know all safety precautions. It is also

recommended that you do a thorough inspection of the turf foam marker before operation. Prior to use, ensure that all hoses are

attached and undamaged and that the wiring harnesses are properly plugged together and connected to an adequate power source.

1. Fill the foam solution tank with the proper mixture of

water and an approved foam concentrate, according to

the foam concentrate's manufacturer.

2. Do Not use dish soap, hand soap, or any other unapproved

solution in the turf foam marker.

5. If you are attaching the discharge tube to a sprayer

boom, pay close attention to the positioning of the

discharge hose. The hose should be positioned in

an manner such that it won't be kinked or pinched

when the boom is in the folded or unfolded position.

Remember to also account for boom height adjustment

or other movements that the hose will be subject to.

6. With the discharge hoses in the correct position, fasten

them with the included cable ties.

Mounting the Turf Foam Marker

d

to compressor

f