Drawing Number: 21075

Revision: C

ECN Number: 47023

OPERATION MANUAL FOR

QUARTZ PRESSURE SENSORS

SERIES 102

SERIES 113

2

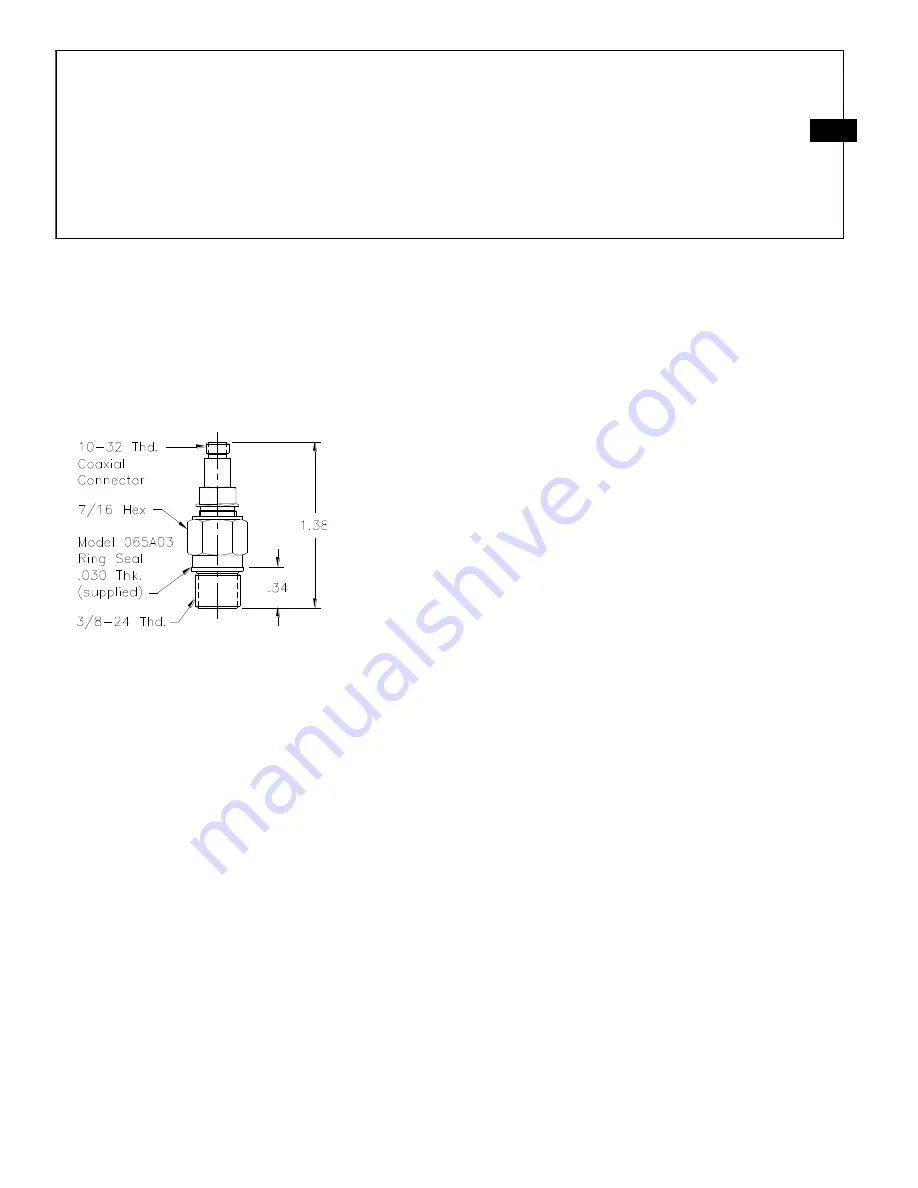

threaded adaptor with floating clamp nut to allow

adjustment of diaphragm mounting depth where it is

necessary to adapt to various wall thicknesses. These

models are supplied only as low-pressure (250 psi

and 100 psi) sensors and are also "off ground".

Models 102A21 and 102A22 are high-temperature

ICP

®

versions to 400

F (204

C), with a 3/8-24

straight threads adaptor and 1/8-27 NPT adaptor,

respectively.

Series 102: Thread Mount Design, Ground-

Isolated Sensor

3.0 INSTALLATION

This manual contains outline and installation

information for your specific model.

Prepare

mounting

ports

in accordance with

instructions given in specific installation drawings,

paying particular attention to sealing surfaces. These

surfaces must be smooth and free from chatter marks,

nicks and other irregularities which could preclude a

pressure tight seal.

To fully realize the high-frequency response

capabilities of this sensor series, flush mounting of

the diaphragm must be used.

In some cases, where flash temperatures such as those

generated by blasts and shock fronts are present, it

may be necessary to thermally insulate the diaphragm

to minimize signals generated by these effects.

Common black vinyl electrical tape has been found to

be an effective insulating material in many cases.

One or more layers may be used across the end of

diaphragm and adaptor.

A silicone rubber coating approximately .010” thick

has also been proven effective in many applications.

General Electric RTV type 106 is recommended.

Apply the rubber coating to the surface of the

diaphragm and allow it to cure in accordance with the

manufacturer’s instructions. (If you have ordered the

CA option,

ablative coated models, further protection

will not be necessary.)

Although ICP

®

sensors have low-output impedance

and in general are not affected by moisture, in

extreme environments it is good practice to protect

cable connections with shrink tubing.

It is not necessary to use low-noise cable with this

sensor series. In fact, an optional Model 070B09

Solder Connector Adaptor allows the use of ordinary

two-wire cable if desired.

4.0

OPERATION

It is only necessary to supply the sensor with a 2 to 20

mA constant current at +20 to +30 VDC through a

current-regulating diode or equivalent circuit. (See

guide G-0001B for powering and signal utilization

information pertaining to all ICP

®

instrumentation).

Most of the signal conditioners manufactured by PCB

have an adjustable current feature allowing a choice

of input currents from 2 to 20 mA. In general, for

lowest noise (best resolution), choose the lower

current ranges. For driving long cables (to several

thousand feet), use higher current, up to 20 mA

maximum.

To operate system using a PCB signal conditioner:

1.

Switch power on.

2.

Wait several minutes for the IC ampli-

fier to turn on and stabilize.

3.

Proceed with measurements.