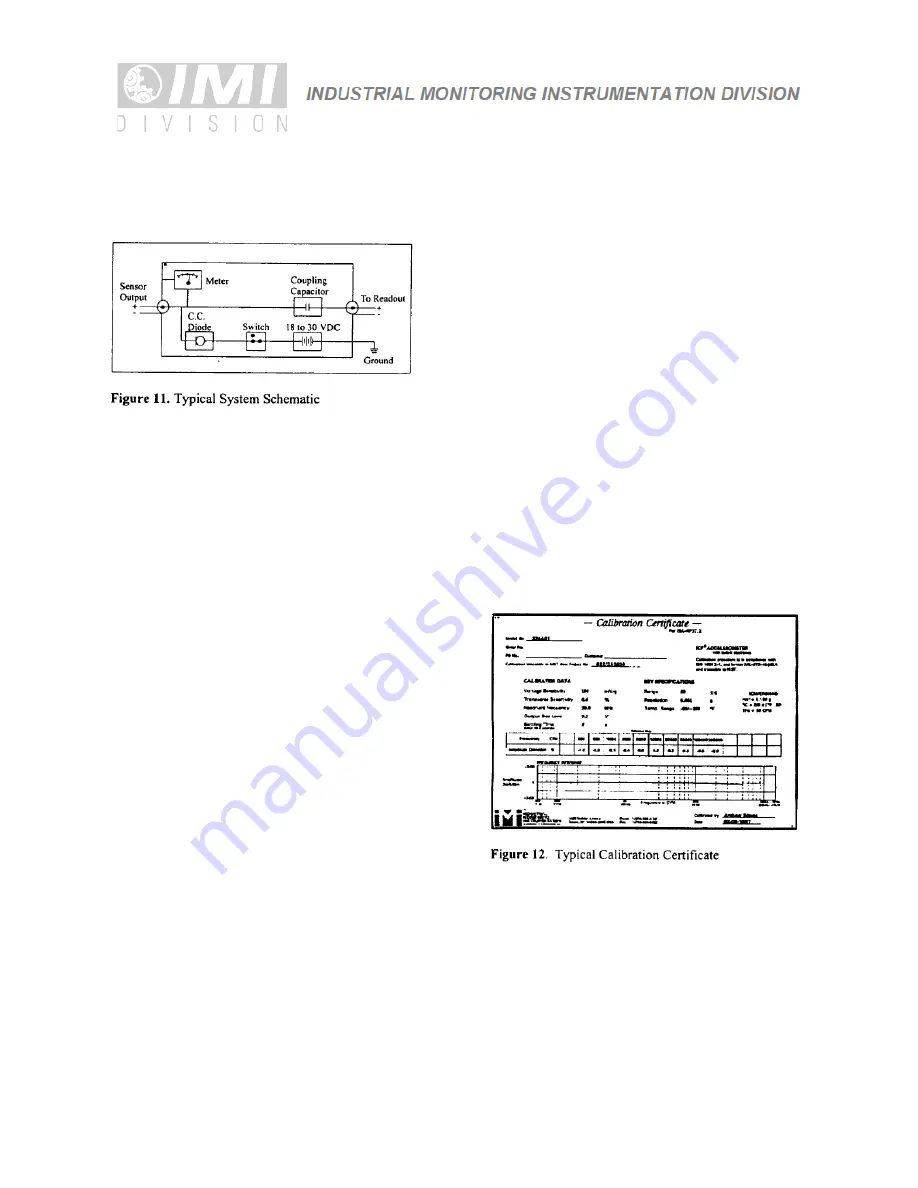

6.0 POWERING

All ICP® sensors require constant current excitation

for proper operation. For this reason only use

approved constant-current sources. A typical system

schematic is shown in Figure 11.

The power supply consists of a regulated 18 to 30

VDC source. In general, battery-powered devices

offer

versatility

for

portable,

low-noise

measurements, whereas line-powered units provide

the capability for continuous monitoring. This power

is regulated by a current-limiting circuit, which

provides the constant-current excitation required for

proper operation of sensors with integral

electronics.

Note:

Under no circumstances should a voltage be

supplied to an ICP® accelerometer without a current-

regulating diode or equivalent electrical circuit.

A capacitor at the output stage of the device

removes the sensor output bias voltage from the

measurement signal. This provides a zero-based, AC-

coupled output compatible with most standard

readout devices.

Today, many FFT analyzers, data acquisition

modules, and data collectors have constant-current

excitation for direct use with ICP® sensors. However,

before using this feature, check that the supply

voltage and constant current are adequate for use

with your sensor. Please contact the respective

signal conditioner manufacturer or check the

product manual for more information.

7.0 OPERATING

After completing the system setup, switch on the

conditioner, the meter (or LED) and allow the sensor

to power up. If a faulty condition is monitored, first

check all system connections, then check the

functionality of the cable and signal conditioner. If

the system still does not operate properly, consult

an IMI Application Engineer.

Note:

Always operate the accelerometer within the

limitations listed on the Specification Sheet of your

sensor. Operating the device outside of its

parameters can cause temporary or permanent

damage to the sensor.

8.0 ACCELEROMETER CALIBRATION

Note:

It is good measurement practice to verify the

performance of each accelerometer before and after

each measurement.

Accelerometers

are

precision

measuring

instruments. They are highly engineered to provide

accurate electrical signals representative of the

vibration being monitored. Each sensor is calibrated

by comparison to a known acceleration level. Some

calibrations include frequency response curves,

resonant

frequency

measurements,

transvers

sensitivity, and many other valuable tests.

Applications requiring a high degree of accuracy or

those in plants requiring certification and traceability

require full calibration test results.

Some applications have much less stringent

requirements for calibration certification. Simple

sensitivity measurements at a single frequency may

be sufficient; operational verification and certificates

of conformance to published specifications may

satisfy many plants’ calibration needs. Reducing the

final calibration requirements reduces the cost of

manufacturing the sensor and should lower the price

for predictive maintenance users.