PCB Load & Torque, Inc.

Toll-Free in USA 866-684-7107

716-684-0001

www.pcbloadtorque.com

DUAL BRIDGE LOAD CELL OPERATION MANUAL

3

3.2 Standard Components

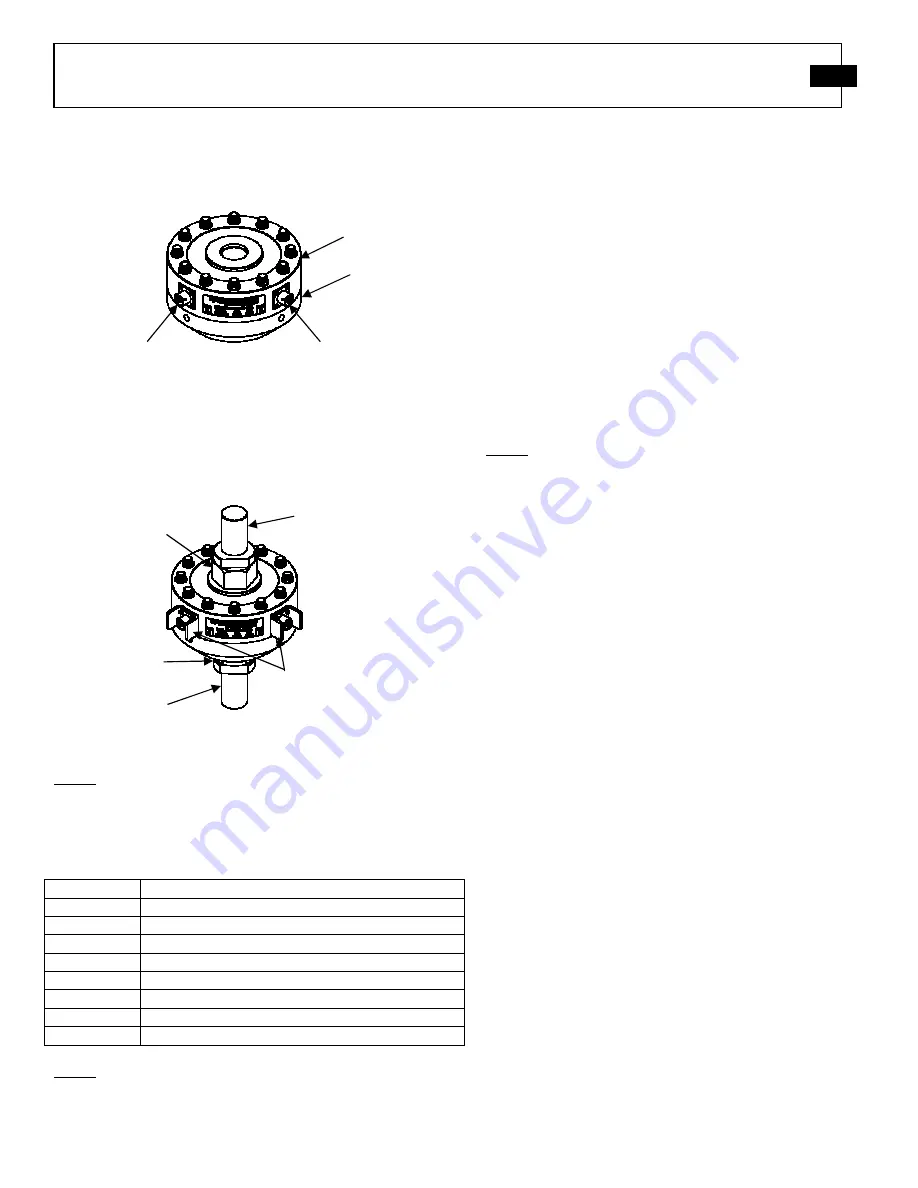

The following figure describes the standard components of the

dual bridge fatigue-rated load cells.

3.3 Optional Components

The following figure describes the optional components of the

dual bridge fatigue-rated load cells.

NOTE: Connector protectors are standard on 8” and 11”

models.

Table 3 describes the available optional components

NOTE: Pre-tension studs include the threaded stud and the

jam nut.

4.0 MECHANICAL INSTALLATION

Standard components of the dual bridge fatigue-rated load

cells have all been installed to factory specified values for

optimum performance. The following mechanical installation

instructions should be observed if optional components are to

be used.

4.1 Mounting Bases

All low-profile load cells are calibrated and supplied with a

factory installed standard mounting base. An optional

custom (customer supplied) mounting base can, with special

arrangements, be installed and used for calibration.

However, there will be an extra charge for removal of the

standard base, and installation of the load cell on the

customer’s base / fixture.

NOTE: To insure catalog performance specifications are met

the customer’s supplied fixture or base must be flat to

within 0.0002 inch and provide similar stiffness and

hardness to a factory base.

Unless otherwise specified/requested, the base and load cell

are calibrated as a unit. It is important to note that the

performance of the load cell may be affected if the factory-

installed mounting base is removed or modified.

4.2 Mounting Load Cell to a Standard Base or

Custom Fixture

If the load cell is to be mounted to a custom base or fixture, it

is necessary to consider the following:

1.

The thickness of the new base or fixture must not be

any thinner than the original base supplied with the

load cell. Materials used must have the same

temperature coefficient of expansion (for example,

4140 Steel or 2024-T4 Aluminum for 250,500 and

1,000 capacity aluminum cells).

2.

The mounting surface must be flat (within 0.0002

inches), and steel fixtures must have a hardness of

Rockwell C 33 to 37.

3.

The threaded holes and under-head of the fasteners

must be lightly lubricated with 30 weight oil or

equivalent prior to tightening the mounting bolts.

4.

Refer to Table 4 for the final tightening torque

required for each bolt size.

5.

Tighten the bolts in an incremental cross pattern with

the following sequence: start with all bolts finger

tight followed by 25%, 50% and finally 100% of the

required torque being applied.

Load Cell

Tension

Base

Connector A

Connector B

Connector

Protector

Pre-Tension

Stud

Pre-Tension

Stud

Jam Nut

Jam Nut

Figure 2

– Standard Components

Figure 3

– Optional Components

Item Number

Item Description

084A40

Lifting Rings (side), 1411 Series

084A41

Lifting Plug (top), 1411 Series

084A55

Pre-Tension Stud (5/8”-18 Thread), 1403 Series

084A56

Pre-Tension Stud (1 ¼”-12 Thread), 1404 Series

084A57

Pre-Tension Stud (1 ¾”-12 Thread), 1408 Series

084A58

Pre-Tension Stud (2 ¾”-8 Thread), 1411 Series

084A59

Pre-Tension Stud (2 ¾”-8 to 1 ¾”-12 Thread) 1411 Series

084A90

Connector Protector, 1403 and 1404 Series

Table 3

– Optional Components