PCB Load & Torque, Inc.

Toll-Free in USA 866-684-7107

716-684-0001

www.pcbloadtorque.com

DUAL BRIDGE LOAD CELL OPERATION MANUAL

8

Dual bridge fatigue rated load cells, when mounted on the

factory supplied base, are barometric compensated through a

small port located in one of the spanner wrench holes on the

base.

The bolts used to install bases at the factory have been

tightened to specifications to prevent loosening under normal

usage. However, if the base has been removed for any reason,

or the load cell has been mounted on a custom fixture without

the base, it is a good idea to periodically test the mounting bolt

tightness using a calibrated torque or click wrench.

11.0 TROUBLE SHOOTING

Proper performance of a load cell requires careful attention to

both electrical and mechanical aspects of the measurement

system. A basic understanding of the electrical and

mechanical installation requirements is recommended.

11.1 Mechanical Trouble Shooting

A mechanical checklist includes:

1.

Check for proper installation of load cell.

2.

Check for properly tightened bolts.

11.2 Electrical Trouble Shooting

An electrical checklist should start with:

1.

Check cables for proper wiring.

2.

Inspect for loose or dirty electrical connections.

3.

Check for improper shield grounds.

4.

Check for proper grounding of the structure that the

load cell is mounted on.

5.

Check the signal conditioning electronics for proper

setup.

6.

Check

the

insulation

resistance

of

shielded

conductors for short circuits.

7.

Check isolation resistance, load cell flexure to

conductors.

8.

Check load cell bridge resistances, (A-D) excitation

and (B-C) the signal leads.

9.

Check bridge balance.

10.

Keep a record of your observations, correct problems,

or contact PCB factory for assistance.

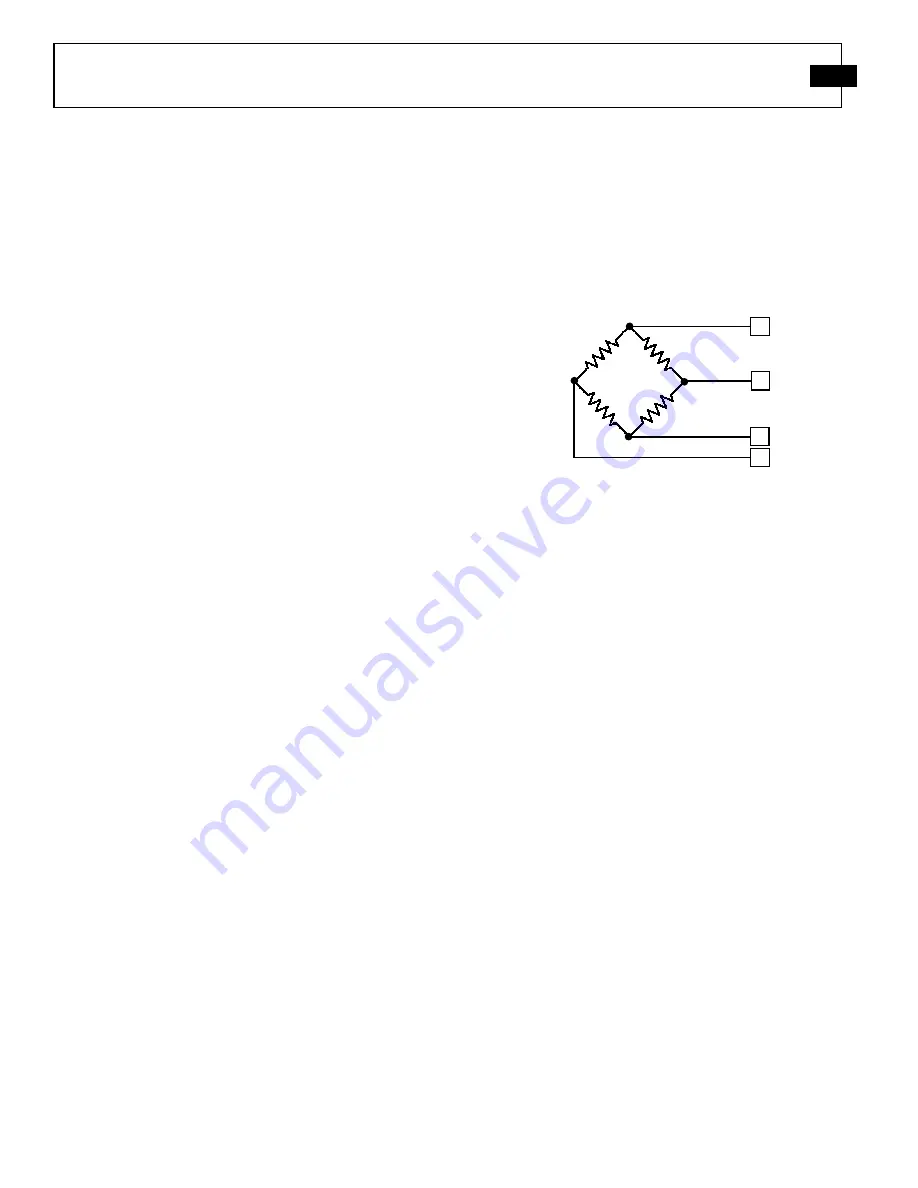

11.2.1 Estimating Bridge Balance using an Ohm Meter

A load cell that has been severely overloaded will exhibit a

significant zero offset in the Wheatstone bridge. It can be

useful to estimate the bridge unbalance using a digital ohm

meter with resolution of at least 0.1 ohm.

Following the Western Region wiring diagram measure the

resistances for each leg of the bridge, i.e.: R

AB

, R

AC

, R

DB

, and

R

DC

.

1.

Estimate the Zero Offset (mV/V):

Zero Offset = 1.4 x (R

AC

- R

AB

+ R

DB

- R

CD

)

2.

Estimate the Bridge Unbalance (% Full Scale):

Bridge Unbalance = 100 x (Zero Offset / Output

FS

)

Where:

Output

FS

= Full Scale output of the load cell (mV/V)

A Zero Offset of greater than 10% indicates probable overload

or possible fatigue damage. A load cell that has been

significantly overloaded enough to create a large zero offset is

not repairable. In some instances it may be possible to

temporarily continue to use the load cell by attempting to

balance the bridge through use of external resistors. However,

the user should expect that such a load cell no longer will meet

the

performance

parameters

related

to

its

original

specifications. (User beware!!)

12.0 CALIBRATION / REPAIR SERVICES

PCB Load & Torque offers calibration and repair services.

The PCB Calibration Laboratory in Farmington Hills,

Michigan is A2LA Accredited per ISO/IEC 17025.

Standard calibration certificates list five force points

ascending and one point descending. Additional data points

are available at extra cost upon request. A 60 K ohm (

±

0.01%)

shunt calibration resistor is supplied with each load cell

calibration.

D

B

C

A

R

DB

R

CD

R

AB

R

AC

Figure 17

– Wheatstone Bridge