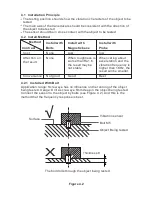

Surface

Vibration sensor

Bolt M5

Object Being tested

√

Ⅹ

Thickness 8

The bolt drills through the object being tested

4.1 Installation Principle

The testing position should show the vibration characters of the object to be

tested.

The main axis of the transducers should be consistent with the direction of

the object to be tested

The sensor should be in close contact with the object to be tested.

4.2 Install Method

Affection on

the result

Cost

Convenience

4.2.1 Installed With Bolt

Application range: Screw eye has no influence on the running of the object

being tested. Usage: Drill a screw eye 5mm deep in the object being tested.

Connect the sensor to the object by bolts (see Figure 4.2). And this is the

method that the frequency response is best.

Figure 4.2

Method

Contrast

Install with

Probe

low

When caring about

acceleration and the

vibration frequency is

higher than 1KHz, the

result will be smaller.

Best

Install with

Bolts

None

None

Not good

Install with

Magnetic base

When roughness is

worse than Ra1.6,

the result maybe

not stable

Low

Good