5.6 MAX HOLD

To freeze maximum values, just press the Hold key, a symbol ‘Max’ shows on

the display. The meter will hold the max value measured. To exit HOLD, press

the HOLD key again.

5.7 Filter (only valid in acceleration mode)

To diagnose faulty bearings, the high frequency 10k mode (acceleration only)

is used, and by using the optional headphones, the instrument can be used as

an electronic stethoscope and noise from abnormal bearings can be

monitored.

5.8 Analogue output

This AC signal can output to recorder or headphone to listen for any distinct

patterns or noises. Listening method will help to locate the defective

machinery or bearing quickly. Measure all machines at the same points and

compare the results. The sound volume can be adjusted by Volume key. There

are 8 levels from 1 to 8 to select. The level 1 is the lowest amplitude while the

level 8 is the maximum amplitude of output signal. To exit volume setting,

simply wait 5s for the meter to automatically switch to the normal measuring

mode.

5.9 RS-232 Serial PC Interface

The meter is equipped with an RS-232 serial data port. This interface was

designed to operate with enables the user

to capture, store and display readings on a PC. USB and Bluetooth can also

be available via RS232C interface.

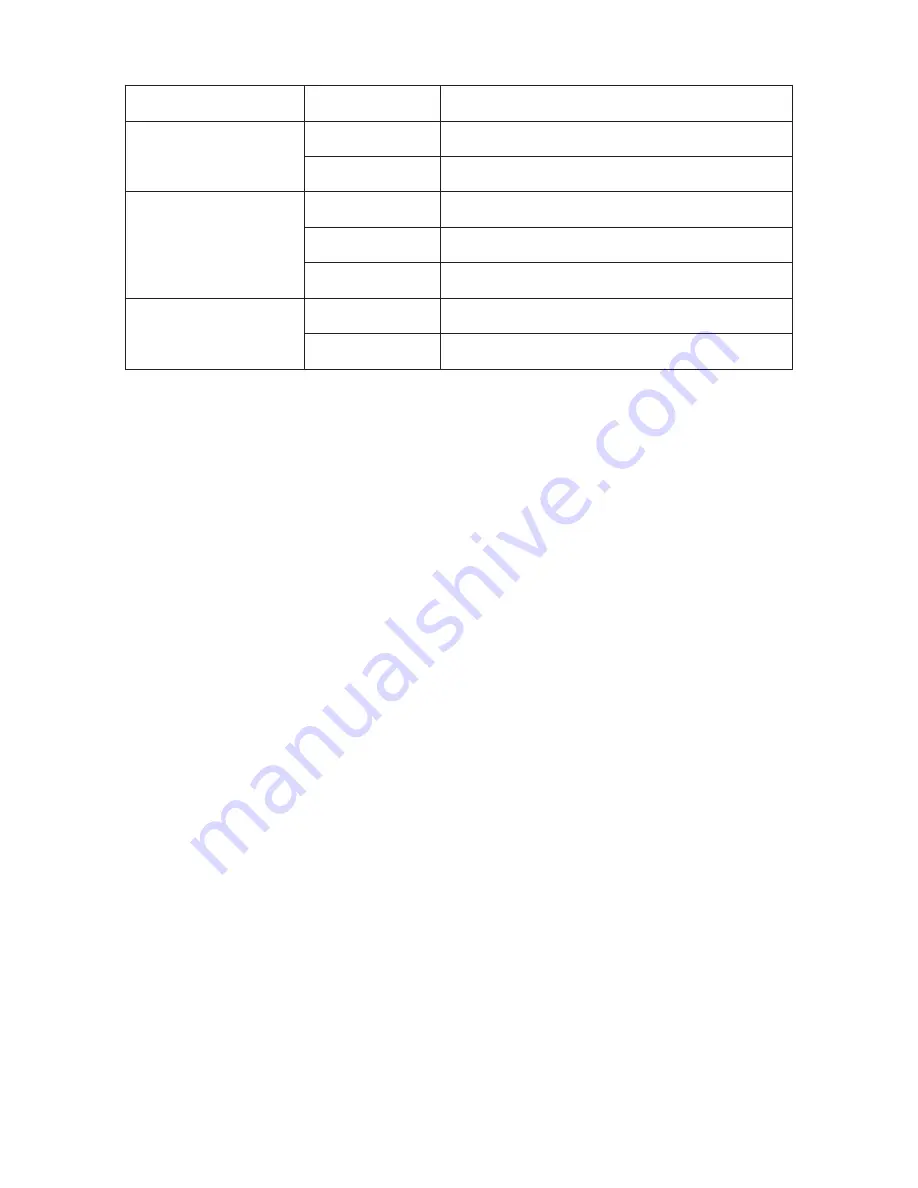

FUNCTION

UNIT

NOTE

VEL

(RMS)

ACC

(Peak)

DISP

(Peak-Peak)

mm/s

Inch/s

g

mm

mil

ft/s

2

m/s

2

millimeters per second

inch/s inches per second

meter per second squared

g-force

feet per second squared

millimeters

one thousandth of an inch

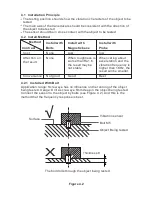

6. AN INTRODUCTION TO VIBRATION MEASUREMENT

Vibration is a reliable indicator of the mechanical health or condition of a

particular machine or product. An ideal machine will have very little or no

vibration indicating that the motor, as well as peripheral devices such as

gearboxes, fans, compressors, etc.,are suitably balanced, aligned, and well

installed. In practice, a very high percentage of installations are far from ideal

, the results of misalignment and imbalance exerting added strain on

supporting components such as bearings. Eventually this leads to added stress

and wear on critical components, resulting in inefficiency, heat generation and

breakdowns. This often occurs at the most inconvenient or uneconomical