times, causing costly production down time. As parts of mechanical equipment

wear and deteriorate, the equipment vibration increases.

Monitoring the vibration of healthy mechanical equipment on an ongoing bas

is, detects any deterioration long before it becomes a critical problem,

allowing spares to be ordered in advance and maintenance to be planned

only when necessary. In this way stocks of expensive and unnecessary

spares can be reduced with obvious financial benefits.

Unscheduled breakdowns result in production losses and the faulty

equipment is usually repaired hastily to get production going as quickly as

possible. Under these stressful conditions staffs are not always able to do

repairs correctly regardless of how conscientious they are, resulting in a high

probability of further early equipment failure.

By implementing a predictive maintenance program with regular

measurements of critical factors like vibration, downtime can not only be

reduced, but planned maintenance is more effective, resulting in improved

product quality and greater productivity.

6.1 Which Parameters Should be Measured?

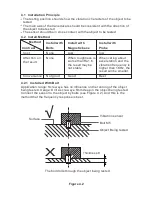

Acceleration, velocity, and displacement are the three tried and tested

parameters, which give accurate and repeatable results?

Velocity is the most commonly used vibration parameter. It is used for

vibration severity measurements in accordance with ISO 2372, BS 4675 or

VDI 2056, which are guidelines for acceptable vibration levels of machinery

in different power categories. See Appendix.

Acceleration has excellent high frequency measurement capabilities, and is

therefore very effective for determining faults in bearings or gearboxes.

Displacement is typically used on low-speed machines because of its good

low frequency response, and is relatively ineffective when monitoring

bearings.

6.2 Evaluating the Overall Vibration Measurements

Three general principles are commonly used to evaluate your vibration

measurement values:

ISO 2372 (10816) Standard Comparison

- Compare values to the limits

established in the ISO 2372 (10816) Standard.

Trend Comparison

- Compare current values with values of Baseline for the

same Points over a period of time.

Comparison with Other Machinery

- Measure several machines of a similar

type under the same conditions and judge the results by mutual comparison.

If possible, you should use all three comparisons to evaluate your

machinery’s condition. ISO 2372 (10816) and trend comparisons should

always be used.

ISO 2372 (10816) Standard Comparison

The ISO 2372 (10816) Standards provide guidance for evaluating vibration

severity in machines operating in the 10 to 200 Hz (600 to 12,000 RPM)

frequency range. Examples of these types of machines are small, direct-

coupled, electric motors and pumps, production motors, medium motors,

generators, steam and gas turbines, turbo-compressors, turbo-pumps and

fans. Some of these machines can be coupled rigidly or flexibly, or connected

through gears. The axis of the rotating shaft may be horizontal, vertical or

inclined at any angle.