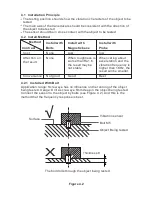

6.3 Measurement Techniques

In general, vibration of anti-friction bearings is best monitored in the load zone

of the bearing. Equipment design often limits the ability to collect data in this

zone. Simply select the Measurement Point which gives the best signal. Avoid

painted surfaces, unloaded bearing zones, housing splits, and structural gaps.

When measuring vibration with a hand-held sensor, it is very important to

collect consistent readings, paying close attention to the sensor’s position on

the machinery, the sensor’s angle to the machinery, and the contact pressure

with which the sensor is held on the machinery.

. Location - always collect at the same point on the machine. Mark locations.

. Position - Vibration should be measured in three directions:

A axial direction; H horizontal direction; V vertical direction

Please define A, H, V as X, Y, Z axes respectively.

. Angle - Always perpendicular to the surface (90

°±

10

°

).

. Pressure - Even, consistent hand pressure must be used (firm, but not so

firm as to dampen the vibration signal). For best results ,use the magnetic

base. If using the stinger/probe is the only method available to collect data, it

is best to use a punch to mark the location for the probe-tip to ensure a

consistent coupling to the housing.

7.1 When the battery symbol appears on the display, it is time to replace the

battery.7.2 Slide the Battery Cover away from the instrument and remove the

batteries.

7.3 Install batteries paying careful attention to polarity.

7. BATTERY REPLACEMENT

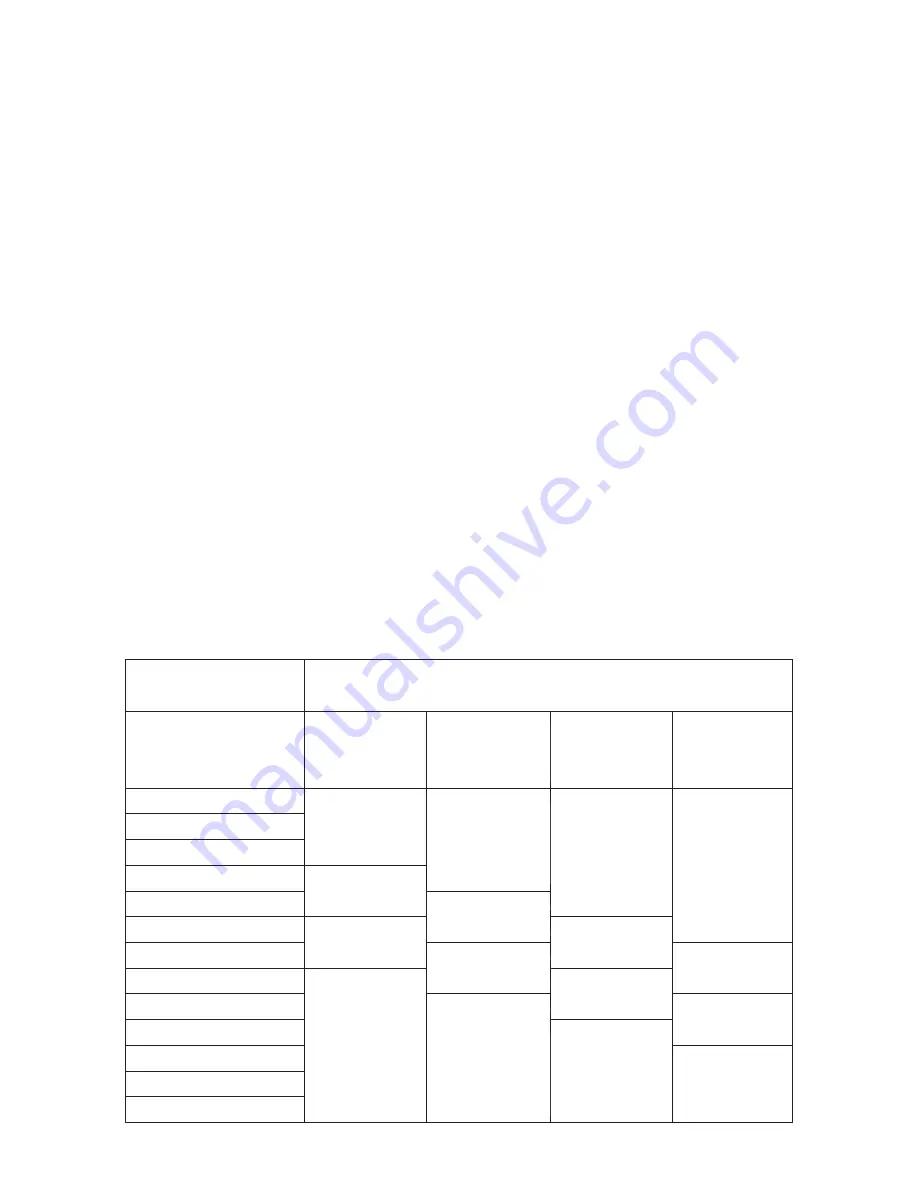

A. Rank of machine vibration (ISO 2372)

Vibration

Amplitude

Vibration

Velocity

V rms (mm/s)

0~0.28

0.28~0.45

0.45~0.71

0.71~1.12

1.12~1.8

1.8~2.8

2.8~4.5

4.5~7.1

7.1~11.2

11.2~18

18~28

28~45

>

45

A

A

A

A

B

B

B

B

C

C

C

C

D

D

D

D

Machine sort

I

II

III

IIII

8. APPENDIX: VIBRATION STANDARDS