14

Section 3

Vibration Issues

Due to the high speed nature of the machine, vibration issues can arise if there are componets that have come

loose or have worn beyond their acceptable service levels.

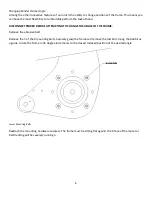

Vibration of Drive Pulley

The drive pulley will vibrate if the set screws have become loose. The drive pulley is supplied with two set

screws locked in place with a thread locking agent. If the set screws have loosened, completely remove each

screw and apply Loctite 249 and reinstall tightly. Let the Loctite cure for 24 hours.

If vibration continues, remove wheel and inspect the bore. Using a precision measuring instrument, measure

the bore of the drive wheel. Check the bore diameter at serveral points around the bore circumference. The

maximum allowed diameter is 0.628” (15.95mm). If the bore has enlargened beyond this, replace drive wheel.

Vibration of Lower or Upper Idler Wheels

First make sure upper and lower spindle handles/knobs are tight. Inspect the tightness of each spindle screw.

If any spindle screw is loose, carefully remove spindle and apply Loctite 249 and reinstall. Torque to 21 ft/lbs

(30 Nm.)

Remove belt and check each idler by hand for any rough or broken bearings. If any bearing is broken, DeBurr-

It! will reload the bearings for free under warranty.

Vibration of Upper Frame

Check the tightness of the two ¼-20 bolts holding the tensioner assembly to the frame. Check the tightness of

the shoulder screw holding the main handle to the frame.

Check the integrity of the two urethane washers in between the lower and upper frame. Reinstall the

mounting bolts to so the nylon nut is flush with the end of mounting screw.

Vibration of the Lower Frame

Check the four mounting bolts for tightness.

High Frequency Vibration on Work Rest or Belt Rest

Check all mounting hardware for tightness. Check gusset welds for cracks on belt rest.

Summary of Contents for DeBurr-It! 248-3

Page 5: ...5 ...