11

c. to adjust the brightness, press “+” or “-“, to activate other options, press

“

▽”

or

“△”

to select

.

d. once the options is selected, press “+” or “-“ to adjust.

e. when adjustments finish, press button

“

/OK

”

to confirm and exit.

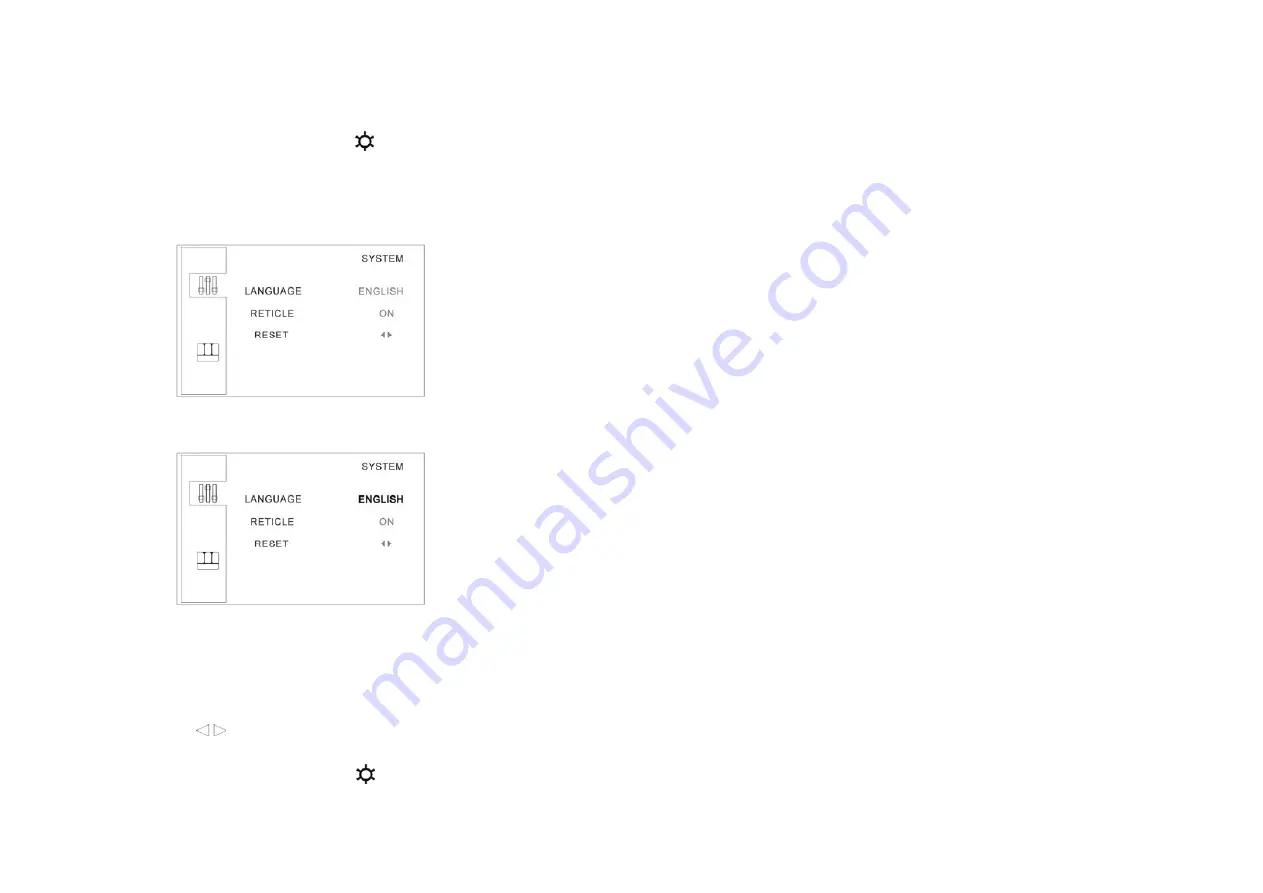

System “settings”:

a. press “MENU” to enter into the sub-menu “image”.

b. press

“▽”

or

“△”

to enter into sub-menu “settings”.

c. press ”menu”, then option “language” is selected and ready for

adjustment.

d. to change the language, press “+” or “-“.

e. to select “reticle”, press the button

“▽”

, then the options “on” “off” are

selected, press “+” or “-“ to activate or close “reticle”.

f. to recover the factory settings, press

“▽”

or

“△”

to select the option

“reset” thus

“

”

is ready for choice, then press “+” or “-“ to

recover or exit the factory settings.

g. when adjustments finish, press button

“

/OK

”

to confirm and exit.

12

Installation of the USB2.0 access driver and the operation processes

:

For installation steps, please refer to “Installation manual of the USB2.0

access driver”.

Errors and dysfunctions diagnosis/analysis:

1. Vague image:

Generally results from the improperly adjusted working distance or the

lens focus, please re-check and make sure the working distance is approx

30mm as required.

2. Image is dim, unclear, colorless, red, and with “snow stains”:

Generally results from weak lightness/brightness, please adjust

lightness/brightness properly strong.

3. Image is too white:

Generally results from strong lightness/brightness, please adjust

lightness/brightness to a properly extent.

4. Image with white spot:

Generally results from refraction of the light beam from the tested object,

please adjust the light incidence and the lightness/brightness to a properly

extent. Normally, scattering light is a better mean of illumination.

5. Malfunction of rotating watching device

The rotating watching device is drived by micro-motor. Normally if it is

not working that is not rotating. The reason may be mechanical error or

electrical failure.

When the watching device is not rotating, please check it carefully and

find the reason. Observation: Incline the unit, watch the small gear of

micro-motor is turning, if it is turning, mean the gear coupling between

small gear and big gear is too loosen. Listening: if you can hear some noise

from the inside of micro-motor, it mean the gear coupling between small

gear and big gear is too tight. The mechanical part after transportation or

long time using, it may cause the gear coupling is too tight or loosen. when it

happens, need to loosen the adjusting screws of gear coupling, then switch

on motor, let the watching device rotating, then tight the four screws. If it

still not works, please check electrical parts.

The motor work at 12V DC,power supply from the bottom base, when

motor not working, first check if the power supply to motor is normal or

not,then check the power cable and socket. Usually there is little possibility