We will give you the measurements for the hinge line then you will add ¼ front and rear

and make marks top and bottom the cut away the control surface and finish the edges to

the lines you have drawn.

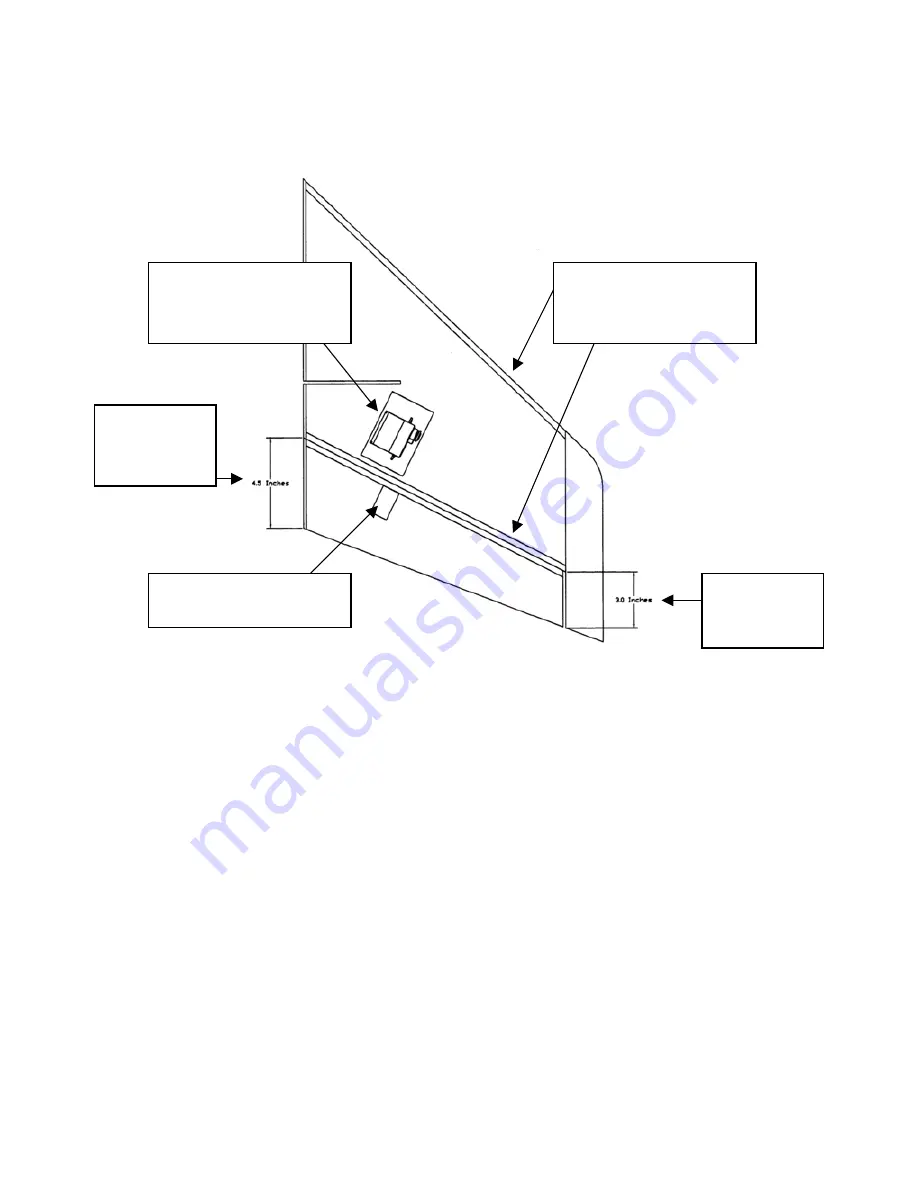

Stabilizer Detail

Servo pocket (2 x 3) set

just behind spar and

next to Stabilizer TE

Leading edge and

trailing edge of wing

made of ¼ balsa stock

Hinge line is

4 –1/2 Inches

at root

Control Horn located in

line with servo output

Hinge line is

3 Inches at

tip

Cut away the elevators using the above diagram. Use the supplied ¼ x 2 x 36 balsa sheet

to make up all the leading and trailing edges. Sand to suit as you did with the wing.

Add the balsa stabilizer tip and sand and shape to suit.

Install servo, control horn and base and use supplied 4-40 materials for control runs. The

servo lead is to pass through the hole in SF1 and into the fuselage.

Hinge the stabilizer with the four supplied flat nylon hinges and ensure you have

clearance against fuselage for freedom of movement.

When the fit of all is as you like it, install SF1 onto the stabilizer and sand flush with

sheeting surface.

The ¼ birch dowel is epoxied into the hole in SF1 and should extend into the foam

approximately ¾ of an inch.

37