-17-

Chapter 2 Product Brief Introduction

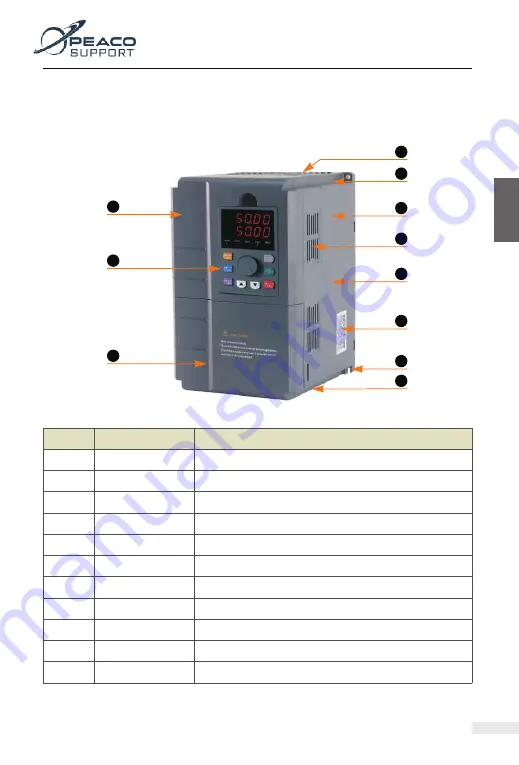

2.5 All components schematic diagram of AC drive

The following picture is all components and names of below 22KW plastic shell

AC drive.

4

5

6

7

8

10

11

9

1

2

3

No.

Name

Description

❶

Cabinet-cover

Protect the internal components.

❷

Keypad

Refer to chapter4 "Keypad operating procedures."

❸

Lower-cover

Protect the internal components.

❹

Fan-cover

Protection fan.

❺

Lower House

Including Fan and

heat sink

❻

Middle House

Including Power Boards

❼

Dust prevention

To Prevent Dust

❽

Bottom Board

Inverter protection

❾

Apron

Convenient input and output wiring.

❿

Series Label

Refer to 2.3 "

Naming Rules

".

⓫

Screw Hole

To make VFD firm with screw

C

h

a

p

te

r

2

Peaco Support FC280 Series VFD User Manual

www.peacosupport.com sales@peacosupport.com Free Shipping Worldwide Reliable Supplier

PEACO SUPPORT