35

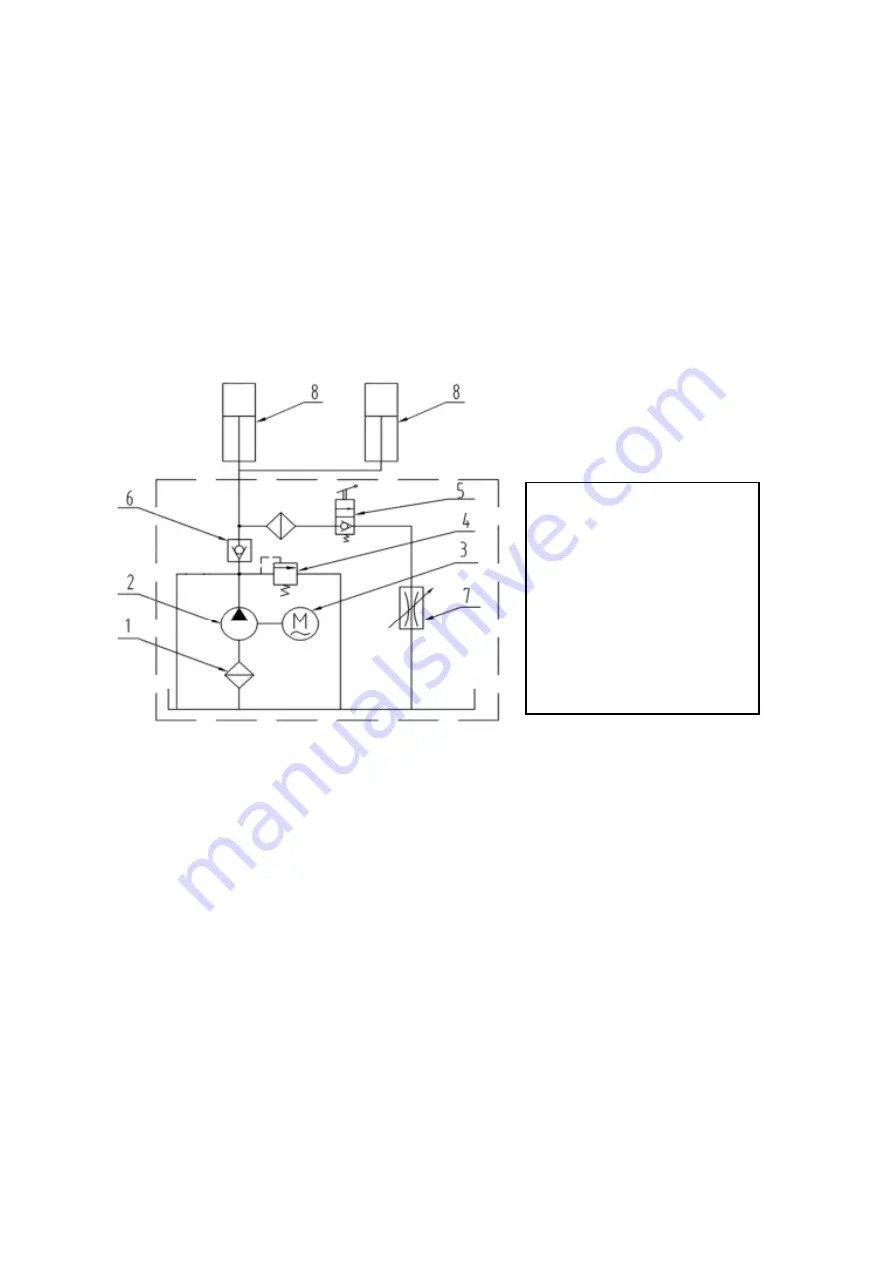

1.

Filter

2.

Gear Pump

3.

Motor

4.

Relief Vavle

5.

Release Vavle

6.

Check Vavle

7.

Throttle Vavle

8.

Cylinder

5. Test with load

After finishing the above adjustment, perform a test run of the lift with a load. Run

the lift in low position for the first few cycles, make sure the lift can rise and lower

synchronously, the Safety Device can lock and release synchronously. And then test

run the lift to the top completely. If there is anything improper, repeat the above

adjustments until correct.

NOTE: It may be vibrated during the first lifting cycles, please lifting it with load

for several times, the air would be bled and the vibration would be

disappeared automatically.

Fig. 50