8

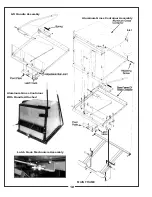

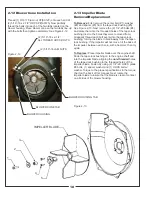

2-6 PTO Handle Assembly Installation

Mount the PTO handle assembly P#(A0603) to the

universal PTO P#(A0623) using (3) 1/4”-20 x 3/4” HHCS

P#(K1222) and (3) 1/4”-20 nyloc nuts P#(K1128).

Before fastening, make sure that there is room for the

handle to engage and disengage without the handle

hitting the fuel tank. See Figure 2-6 for reference.

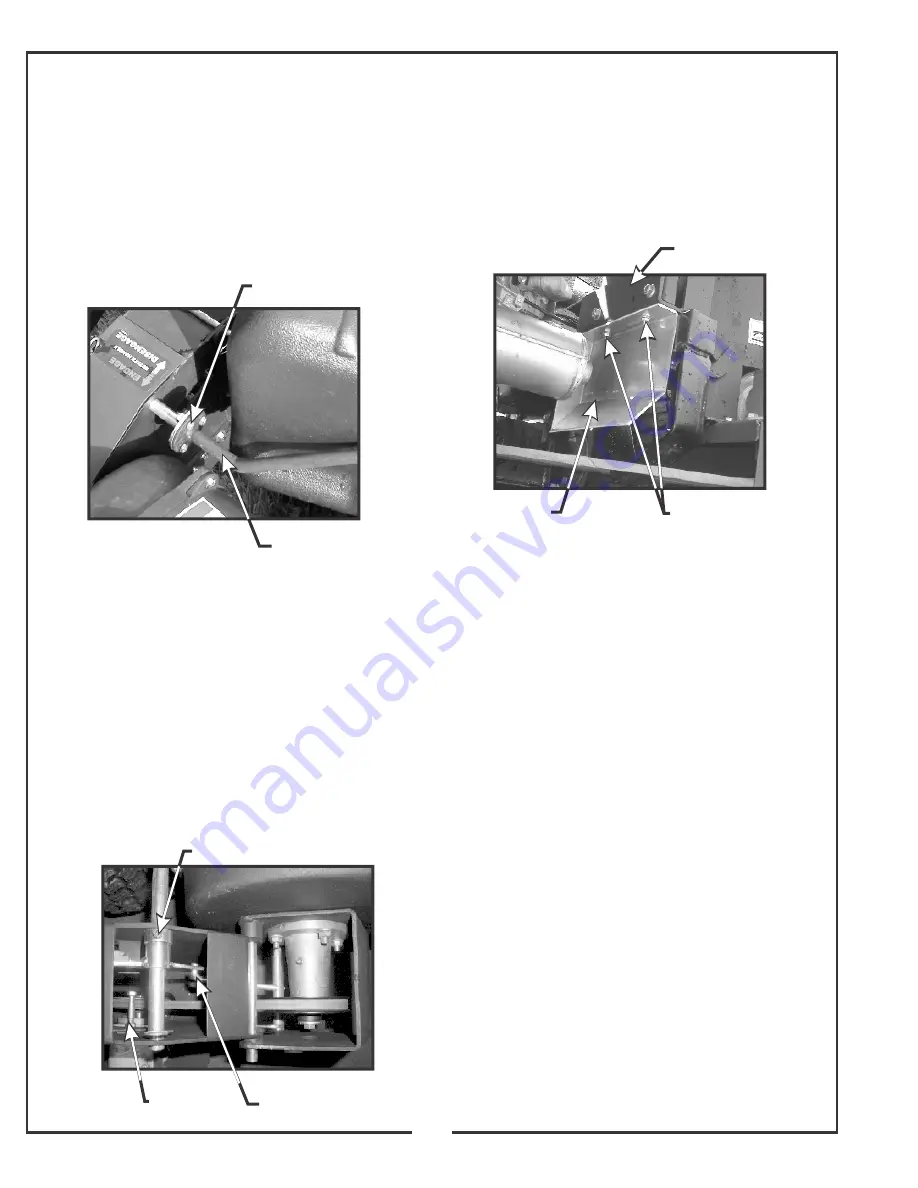

2-7 Cam Assembly Adjustment

The cam assembly P#(A0422), which controls the

blower belt tension, comes from the factory pre-adjusted.

If the belt is too tight or becomes too loose, remove the

hair pin clip P#(K0099) from the belt tension rod

P#(K0326) and pull the “L” end of the rod out of it’s hole

in the cam assembly. The tension rod may then be

screwed out to tighten the belt or screwed in to loosen

the belt. Replace the “L” end into the top hole in the cam

and replace the hair pin clip. Adjust the cam stop bolt

P#(K1159) to allow the cam to rotate slightly over center

when the blower is disengaged (Figure 2-7).

2-8 Exhaust Deflector Installation

Fasten the exhaust deflector P#(C0058) to the

underside of the PTO mount plate assembly P#(A0846)

and fasten using (2) 1/4”-20 x 3/4” HHCS and (2) 1/4”-

20 nyloc nuts. See Figure 2-8.

2-9 Lift Handle Installation

The various parts of the handle assembly P#(A0273)

must be attached to the container frame. Page 10

shows the orientation and location of the components.

Slide the lift handle into the slot in the handle mount

bracket P#(B1730) on the grass container. It may be

necessary to remove the handle grip P#(J0522) to allow

the handle to fit through the slot.

Before attaching the handle, hook one end of the spring

P#(J0176) into the hole on the underside of the handle.

Hook the other end of the spring into the open hole in

the handle mount bracket. Fasten the handle to the

grass container frame by using (1) 3/8”-16 x 2” HHCS

P#(K1208) and (2) 3/8”-16 flange nuts P#(K1215). At

this point the handle can pivot back and forth in the slot

of the handle mount bracket. With the handle in place,

fasten the ball joint P#(K1442) to the end of the latch

rod P#(A0260) (Page 10). Tighten to approximately half

way down the threads of the latch rod. Slide the ball

joint into the hole on the latch hook P#(B1529). Use (1)

5/16”-24 hex nut P#(K1444) and (1) 5/16” lock washer

P#(K0043) to fasten the ball joint to the latch hook.

Attach the opposite end of the latch rod into the handle.

Fasten the rod to the handle by using (1) 3/32” x 3/4”

cotter pin P#(K0094). Adjust the rod to allow the hook to

close the box door completely.

Tension Rod

Figure 2-7.

Cam Stop

Bolt

Cam Assembly

Figure 2-8.

PTO Mount Plate

Assembly

(2)1/4”-20 x 3/4” HHCS

(2)1/4”-20 Nyloc Nuts

Exhaust

Deflector

Figure 2-6.

PTO Handle

Assembly

Fasten Here

Summary of Contents for 21621207-08

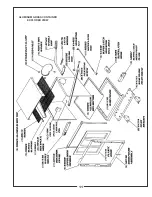

Page 11: ...ALUMINUM GRASS CONTAINER EXPLODED VIEW 11 ...

Page 17: ...PTO Parts List 17 ...

Page 24: ...24 ...

Page 25: ...25 NOTES ...