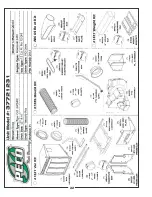

2-25 Weight Kit Installation

The collection system requires that a weight kit is

installed to the front of the mower to counter-balance the

weight of the collection system, when filled with debris.

NOTE:

The (2) weight brackets are secured to the caster

supports first. Then the weight is added to the weight

brackets. It is recommended that two people perform this

procedure. If another person is not available, use a

rolling hydraulic floor jack to keep the weight into

position while you secure the weight to the weight

brackets

Locate the(2) weight brackets P#(B0026). Secure (1)

bracket to each front caster support, using (1) 3/8”-16 x

2-1/8” u-bolt P#(K1119) and (2) 3/8”-16 nylon flange lock

nuts P#(K2038)

PER BRACKET

. Position the weight

bracket as shown in Figure 2-25a. Insert the u-bolt from

the bottom of the caster support tube as shown in Figure

2-25b. Leave the hardware slightly loose until the weight

has been installed.

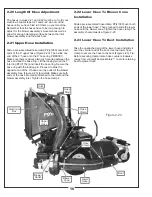

After the weight brackets have been secured to the

caster supports, place (1) weight bar P#(B0035) onto the

(2) weight brackets. It is strongly recommended that

someone assist you in lifting the weight bar into position.

Center the weight bar between the front casters. Secure

the weight bar to the weight bracket using (2) 1/2”-13 x

4-5/16” u-bolts P#(K0331) and (4) 1/2”-13 nylon flange

lock nuts P#(K2012). Tighten the weight bracket

hardware at this time. Refer to Figure 2-25c and 2-25d

for reference.

18

Figure 2-25c

Weight Bar

(2) 1/2”-13 U-Bolts

Figure 2-25a

Weight

Bracket

Caster

Support

Figure 2-25b

(2) 3/8”-16 Nuts

Caster

Support

(1) 3/8”-16 U-Bolt

Figure 2-25d

Weight Bar

(4) 1/2”-13 Nuts

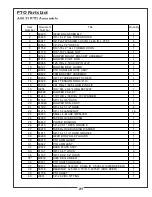

Summary of Contents for 37721231

Page 22: ...22 A0664 Boot Kit ...

Page 23: ...23 B1117 A0664 Boot Kit ...

Page 24: ...24 B1117 A0664 Boot Kit ...

Page 28: ...28 ...

Page 29: ...NOTES ...