19

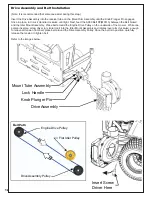

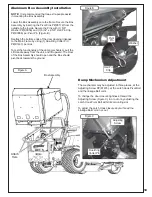

Dump Mechanism Adjustment

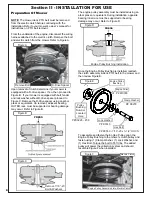

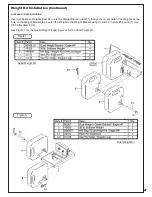

The mechanism may be adjusted in three places, at the

Adjusting Screw P#(K1435), at the Latch Hook Pivot Bolt

and the linkage Ball Joint.

To change the door closure tightness, thread the

Adjusting Screw (Figure C) in or out or by adjusting the

Latch Hook Pivot Bolt within its’ mounting slot.

To adjust the Latch Hook closure angle, thread the

Linkage Ball Joint in or out.

Rue-Ring

Cotter Pin

Adjusting

Screw

Washer

Hair Pin

Clip

Pivot

Pin

Attach

Here

Box Assembly

Figure A

Figure B

Figure C

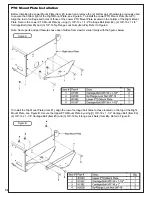

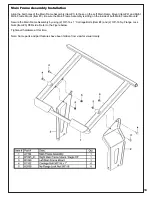

Aluminum Box Assembly Installation

NOTE:

It is recommended that two extra people assist

in mounting the Box Assembly.

Lower the Box Assembly onto the frame. Secure the Box

Assembly by inserting the Pivot Pins P#(K0172) from the

outside to the inside. Secure the Pins with (1) 5/8”

Washer P#(K0058) and (1) 5/32” x 2-5/8” Hair Pin Clip

P#(K0088) per Pivot Pin (Figure B).

Reattach the bottom ends of the door opening linkages

to the Main Frame by using (1) Rue-Ring Cotter Pin

P#(K1437) per side.

To test the functionality of the dump mechanism, pull the

Lift Handle away from the unit, and lift upward. The Door

of the Box Assembly should open and the Box should

pivot back towards the ground.

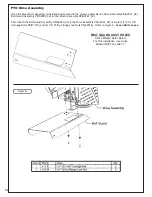

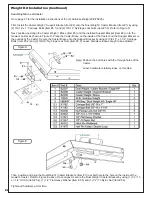

Summary of Contents for 38651202

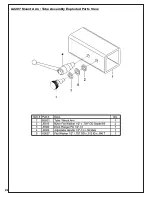

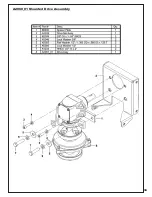

Page 28: ...28 A2207 Mount Arm Tube Assembly Exploded Parts View...

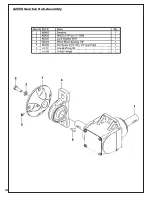

Page 29: ...29 A2092 Idler Arm Assembly A2067_02 Idler Mount Assembly...

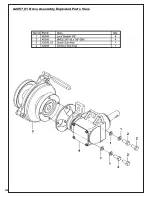

Page 30: ...30 A2058 Gearbox Sub Assembly...

Page 31: ...31 A2059_01 Clutch Sub Assembly...

Page 32: ...32 A2057_01 Drive Assembly Exploded Parts View...

Page 33: ...33 A2060_01 Mounted Drive Assembly...

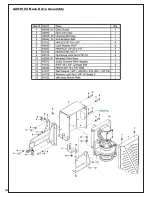

Page 34: ...34 A2039_02 Base Drive Assembly...

Page 35: ...35 A2061_02 Drive Assembly 4 Blade Impeller...

Page 36: ...36 A2100 6512 Box Assembly Standard Model Exploded Parts View...

Page 37: ...37 A2226 6512 Box Assembly Base Model Exploded Parts View...

Page 38: ...38 A2226 6512 Box Assembly Base Model Exploded Parts List...

Page 39: ...39 A2107 Latch Rod Assembly...

Page 40: ...40...

Page 44: ...44...