43

3. Make sure all shields are in place and in good

condition. Repair or replace any missing or damaged

shields.

4. Perform lubrication per instructions.

5. Listen for abnormal sounds, which might indicate

loose parts, damaged bearings, or other damage.

Correct any deficiency before continuing operation.

6. With the engine off, engage the blower assembly.

Check the belt tension and inspect the pulley belt for

cracks or tears.

7. Check for wear or deterioration of the upper or lower

hoses. If there are any portions of the hose that have

been torn or worn through, replace immediately.

After Each Use:

1. Clean all debris from machine especially from the

container, underneath the belt shields, and safety

decals. Replace any missing or illegible decals.

2. Inspect the unit for worn or damaged components.

Repair or replace before the next use. Any

replacement component installed during repair shall

include the component’s current safety decal specified

by the manufacturers to be affixed to the component.

3. Under normal usage, the bag material is subject to

deterioration and wear and should therefore be

frequently checked for necessary replacement. Any

replacement bag should be checked to ensure

compliance with the original manufacturer’s

recommendations or specifications.

4. Check belt for proper tension.

DOCUMENT THE FOLLOWING INFORMATION FOR FUTURE REFERENCE

Unit Model Number:_______________________________________________

Unit Engine Size:__________________________________________________

Unit Serial Number:________________________________________________

Date of purchase:________/________/_________

Dealer/Distributor Name:__________________________________________

Address: _________________________________ State:_______ Zip:_______

Phone Number: ____________________________________________________

New PECO, Inc.

10 Walden Dr | Arden, North Carolina 28704

Phone: 1-800-438-5823 | 828-684-1234

Fax: 828-684-0858

Email:

peco@lawnvac.com

Website: www.lawnvac.com

4-2 Lubrication

Gearbox:

NOTE:

The gearbox is filled with 6.0 oz. of Mobilube

HD Plus 80W-90 oil and permanently sealed. There is

no need for scheduled lubrication. The oil level should

only be checked if a leak is observed or if a change in

gearbox noise is noticed.

Operators are recommended to check for leaks weekly.

If a leak is observed, both the gasket and the seals are

recommended to be replaced.

Replace the oil using 5.5 oz. of the recommended

Mobilube HD Plus 80W-90 oil. Be sure to not overfill.

Blower Assembly:

NOTE:

The following is for older PTO models that

contain a greaseable zirc fitting. Newer models

contain maintenance-free bearings and are without

a greasable fitting.

.

1. On initial use: Grease the fitting on the blower shaft.

2. Every 25 hours of use: Re-grease the grease fitting.

NOTE:

Use only white lithium based grease for

lubrication of the shaft on the blower assembly.

SECTION V - PARTS & SERVICE

5-1 Parts And Service Information

Collection system owners should record the name and

telephone number of their Service Center. Your Service

Center will be happy to supply replacement parts,

accessories, and do any service or repairs to your

collection system. If for any reason your Service Center

is unable to service your collection system or supply

replacement parts, contact New PECO, Inc. and include

the following information on the chart below.

Summary of Contents for 38651202

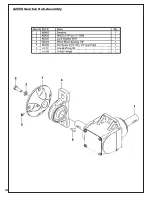

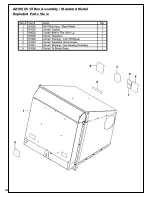

Page 28: ...28 A2207 Mount Arm Tube Assembly Exploded Parts View...

Page 29: ...29 A2092 Idler Arm Assembly A2067_02 Idler Mount Assembly...

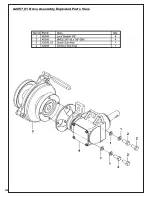

Page 30: ...30 A2058 Gearbox Sub Assembly...

Page 31: ...31 A2059_01 Clutch Sub Assembly...

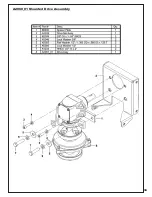

Page 32: ...32 A2057_01 Drive Assembly Exploded Parts View...

Page 33: ...33 A2060_01 Mounted Drive Assembly...

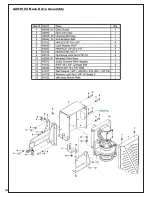

Page 34: ...34 A2039_02 Base Drive Assembly...

Page 35: ...35 A2061_02 Drive Assembly 4 Blade Impeller...

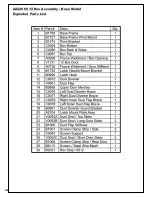

Page 36: ...36 A2100 6512 Box Assembly Standard Model Exploded Parts View...

Page 37: ...37 A2226 6512 Box Assembly Base Model Exploded Parts View...

Page 38: ...38 A2226 6512 Box Assembly Base Model Exploded Parts List...

Page 39: ...39 A2107 Latch Rod Assembly...

Page 40: ...40...

Page 44: ...44...