13

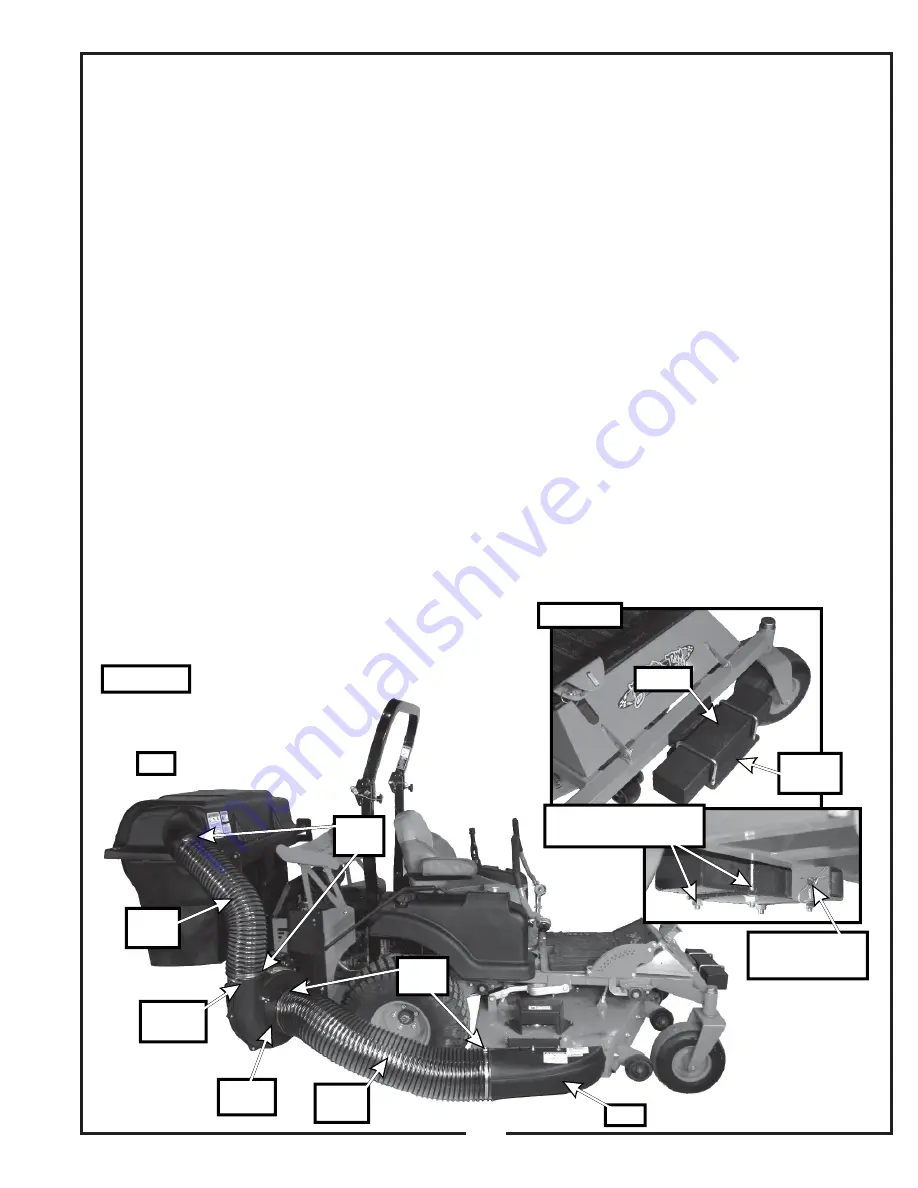

2-13 Lengths Of Hose Adjustment

The hoses in steps 2-14 and 2-15 must be cut to fit your

machine. Follow steps 2-14 and 2-15. Do not cut the

hoses until you have tried to fit them on your machine.

Remember that the hoses have to be long enough to

allow for enough clamping surface between the inlet,

blower assembly, and the deck boot.

2-14 Upper Hose Installation

Fasten the inlet to the plastic top by sliding the inlet from

the inside of the top to the outside and lock into place.

Slide a 6” upper hose clamp P#(J0060) onto both ends

of the 6” upper hose (Figure 2-13). Then slide one

end of the 6” hose onto the inlet. Make sure there is

about a two-inch overlap between the hose end and the

container inlet. Proceed to slide the opposite end of the

6” hose onto the outlet of the blower assembly. See

Figure 2-13 for details. Make sure both ends of the hose

are clearly attached to the inlet and the blower assembly

inlet. Tighten the hose clamps.

2-15 Lower Hose To Blower Cone

Installation

Slide a 8” hose clamp P#(J0080) over both ends of the

lower hose. Then proceed to slide the lower hose onto

the blower cone. Tighten the hose clamp. The assembly

should look like

.

Figure 2-13

2-16 Lower Hose To Boot Installation

Take the unattached end of the lower hose and slide it

over the circular end of the boot. Use the lower hose

clamp to secure the hose to the boot (

. Tip:

Figure 2-13)

Before securing clamp rotate hose counter-clockwise

(away from yourself) approximately 1” to add in retaining

boot to mower deck.

2-17 Front Weight Installation

Slide the weight bracket assembly P#(A0597) into the

mower’s front receiver hitch (

). Fasten by

Figure 2-17

using (1) 5/8” x 3” clevis pin P#(K0172) and (1) 5/32” x

2-5/8” hair pin clip P#(K0088). When installing the weight

bar (Figure 18) P#(B2220), you should have another

person help position the weight centered onto the weight

bracket assembly. Fasten the weight by using (2) 1/2”-13

U-bolts P#(K0331) and (4) 1/2”-13 flange nuts

P#(K1246). Tighten all nuts and bolts.

Blower

Cone

Blower

Housing

Lower

Hose

Upper

Hose

Inlet

Hose

Clamp

Hose

Clamp

Boot

(1) Clevis Pin

(1) Hair Pin Clip

Weight

Bracket

(2) 1/2”-13 U-Bolts

(4) 1/2”-13 Nyloc Nuts

Weight

Figure 2-13

Figure 2-17