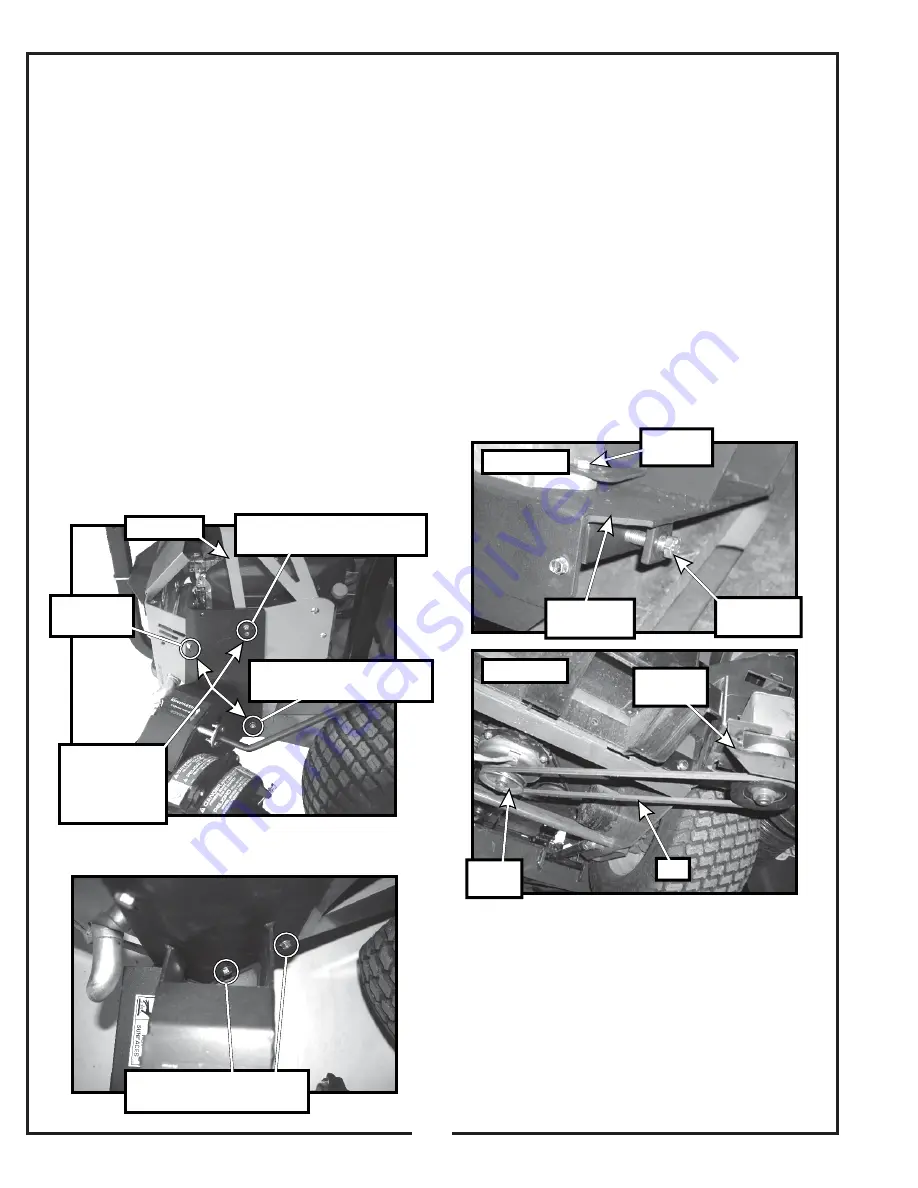

2-2 PTO Assembly Installation

Remove the (2) existing nuts and bolts that secure the

rear guard to the rear frame of the mower. Remove

rear right set of hardware that secures the mower fin

to the rear frame of the mower. There are four sets of

mounting holes on the PTO assembly P#(A0610). For

the Pup Series, use the lower set of mounting holes.

For the Outlaw series, use the upper set of mounting

holes. Align the two lower holes on the PTO assembly,

with the holes on the rear frame of the mower and

secure using (2) 3/8”-16 x 1-1/4” HHCS P#(K1192)

and (2) 3/8”-16 nyloc nut P#(K1216). For the Pup

Series, you may need to drill a hole in the rear guard

using a 5/16” drill bit. Secure the PTO assembly to the

upper portion of the rear guard using (1) 3/8”-16 x 3-

1/4” HHCS and (1) 3/8”-16 nyloc nut. Secure the

mower fin to the rear guard and the PTO assembly

using (1) 5-16”-18 x 1-1/4” G8 HHCS P#(K0118) and

(1) 5/16” nyloc nut P#(K1180). Refer to Figure 2-2a

and Figure 2-2b.

2-3 Belt Installation

Remove the pulley guard P#(B0075) by removing the (2)

1/4”-20 x ½” HHSTS P#(K0353), see page 9, diagram #

38 and #39 for part location. Loosen the (2) bolts that

secure the gear box assembly P#(A0429) to the PTO

mount plate (Figure 2-3a). Loosen the adjustment bolt

P#(K0348) until the gear box assembly is at the far left

adjustment (the gear box is moved towards the mower’s

engine pulley). Connect the kevlar cord belt from the

engine pulley to the lower gear box pulley (Figure 2-3b).

For all engine sizes except for the 31HP Kawasaki, use

the A52K belt P#(M0238). For the 31 HP Kawasaki, use

the A53K belt P#(M0247). To tension the drive belt, turn

the adjustment bolt clockwise until there is 1” of

deflection, with 10-11 lbs. of pressure between the

engine pulley and the gear box pulley. Once the correct

tension of the belt is achieved, tighten the (2) bolts that

secure the gear box assembly.

2-4 Cam Assembly Adjustment

The cam assembly P#(A0422), which controls the

blower belt tension, comes from the factory pre-adjusted.

If the belt is too tight or becomes too loose, remove the

hair pin clip P#(K0099) from the belt tension rod

P#(K0326) and pull the “L” end of the rod out of its hole

in the cam assembly. The tension rod may then be

screwed out to tighten the belt or screwed in to loosen

the belt. Replace the “L” end into the top hole in the cam

and replace the hair pin clip. Adjust the cam stop bolt

P#(K1159) to allow the cam to rotate slightly over center

when the blower is disengaged (Figure 6).

6

Mower Fin

(1) 5/16”-18 x 1-1/4” HHCS

(1) 5/16”-18 Nyloc Nut

Use Top Holes

For Outlaw

Bottom Holes

For Pup

(1) 3/8”-16 x 1-1/4” HHCS

(1) 3/8”-16 Nyloc Nut

Drill On

Pup Series

(2) 3/8”-16 x 1-1/4” HHCS

(2) 3/8”-16 Nyloc Nut

Figure 2-2a

Figure 2-2b

Figure 2-3a

Figure 2-3b

PTO

Mount Plate

Loosen

Gear Box

Adjustment

Bolt

Gear Box

Assembly

Belt

Engine

Pulley