6

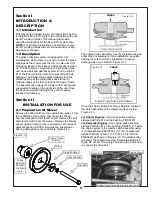

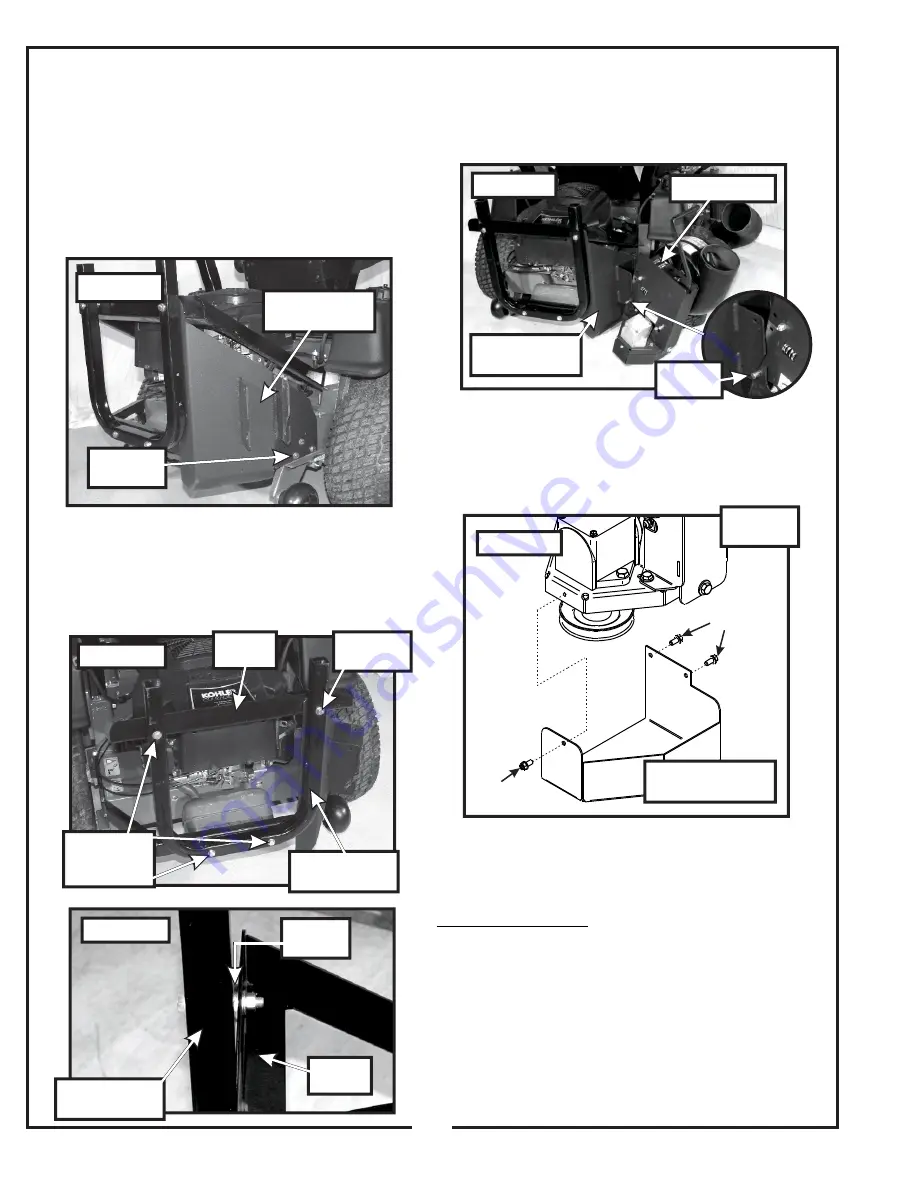

2-2 PTO Mount Plate Assembly

Installation

With the lid assembly removed, disconnect the frame

mounting tube and bumper from the bumper tie. Position

the PTO mount plate assembly P#(A1816) as shown in

Figure 2-2a. Use the existing hardware from the bumper

tie to secure the PTO mount plate assembly to the

bumper tie. Leave the hardware loose until the frame

mounting tube is re-attached.

Secure the frame mounting tube to the frame support tie

using the existing hardware from the frame tube. You will

add (1) washer P#(K1446) between the frame tube and

support tie and (2) washers between the frame tube and

bumper tie. Tighten all the hardware at this time. Refer to

Figure 2-2b and 2-2c.

2-3 PTO Assembly Installation

Insert the PTO assembly P#(A1815) into the slots on the

PTO mount plate assembly as shown in Figure 2-3a.

Remove the gear box pulley guard P#(B0478) and (3)

1/4”-20 x 1/2” HHSTS P#(K0353) from the PTO

assembly in preparation for the belt installation. Refer to

Figure 2-3b.

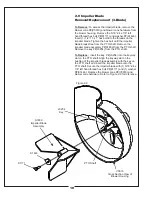

2-4 Belt Installation/Removal and

Adjustment

Installation/Removal:

With the PTO mount pin

P#(B0274) removed, loosen the (4) 5/16”-18 x 3/4”

HHCS P#(K1153) that secure the gear box to the PTO

assembly. Loosen the adjustment bolt (1) 3/8”-16 x 2”

hex bolt P#(K0348). Slide the gearbox towards the

mower until there is enough clearance for the kevlar belt

to slide over both the engine and gearbox pulleys. Install

the A54K kevlar belt P#(M0255). Insert the PTO mount

pin P#(B0274), and secure the pin with (1) hair pin clip

P#(K0086).

Refer to Figures 2-4a through 2-4e.

Existing

Hardware

PTO Mount

Plate Assembly

Figure 2-2a

Add Washer

To Existing

Hardware

Existing

Hardware

Figure 2-2c

Figure 2-2b

Frame

Mounting Tube

Support

Tie

Support

Tie

Frame

Mounting Tube

Add

Washers

Figure 2-3a

PTO Assembly

PTO Mount

Plate Assembly

Mounting

Slots

Figure 2-3b

Remove

Hardware

Remove Gear Box

Pulley Guard

Remove

Hardware

PTO

Assembly

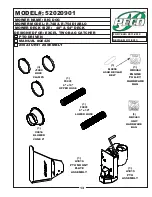

Summary of Contents for 52020901

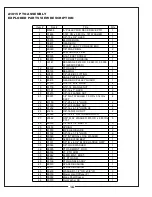

Page 14: ...14...

Page 15: ...15 A1815 PTO ASSEMBLY EXPLODED PARTS VIEW...

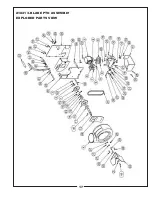

Page 17: ...17 A1841 3 BLADE PTO ASSEMBLY EXPLODED PARTS VIEW...

Page 20: ...19...

Page 21: ...NOTES...