2

PECO BRUSH BLAZER

TABLE OF CONTENTS

SECTION PAGE

Safety Alert Symbols - - - - - - - - - - - - - - - - - - - - - 2

General Safety Rules - - - - - - - - - - - - - - - - - - - - - 3

Safety Decals - - - - - - - - - - - - - - - - - - - - - - - - - - 4

Peco Limited Warranty - - - - - - - - - - - - - - - - - - - - 5

Controls - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6

Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - -

7-10

Tips On Brush Cutting - - - - - - - - - - - - - - - - - - - - 10

Pump Adjustment - - - - - - - - - - - - - - - - - - - - - - - 11

Pump Belt Adjustment - - - - - - - - - - - - - - - - - - - - 12

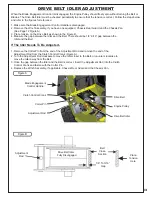

Drive Belt Idler Adjustment - - - - - - - - - - - - - - - - - 13

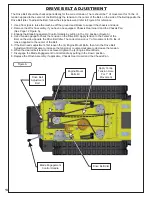

Drive Belt Adjustment - - - - - - - - - - - - - - - - - - - - - 14

Deck Belt Adjustment - - - - - - - - - - - - - - - - - - - - - 15

Mower Deck Pulley Alignment - - - - - - - - - - - - - - - 15

SECTION PAGE

Deck And Drive Belt Removal And Replacement -

16-17

Track Removal/Replacement - - - - - - - - - - - - - - - - 18

Blade Shaft Assembly - - - - - - - - - - - - - - - - - - - - - 19

Blade Replacement - - - - - - - - - - - - - - - - - - - - - - 19

Label Replacement Part Numbers - - - - - - - - - - - - - 20

Regular Maintenance - - - - - - - - - - - - - - - - - - - - - 21

Scheduled Replacement Parts List - - - - - - - - - - - - 22

Hydraulic Oil Specifications - - - - - - - - - - - - - - - - - 22

Exploded Views And Parts Lists - - - - - - - - - - - -

23-38

Torque Specifications - - - - - - - - - - - - - - - - - - - - - 39

California Emission Control Warranty Statement -

40-41

Safety Alert Symbol

This Safety Alert Symbol means:

“ATTENTION! BECOME

ALERT! YOUR SAFETY IS INVOLVED!”

This symbol is used to call attention to safety precautions that

Should be followed by the operator to avoid accidents. When

you see this symbol, carefully read the message that follows

and heed its advice. Failure to comply with safety precautions

could result in death or serious bodily injury.

Safety Signs

The signal words

DANGER, WARNING,

and

CAUTION

are used on the equipment safety signs. These words

are intended to alert the viewer to the existence and the degree of hazard seriousness.

DANGER

!

CAUTION

This signal word indicates a potentially hazardous situation which, if not

avoided, will result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

It may also be used to alert against unsafe practices.

This signal word indicates a potentially hazardous situation which, if not

avoided, will result in minor or moderate injury.

It may also be used to alert against unsafe practices.

White letters on

RED

Black letters on

ORANGE

Black letters on

YELLOW

WARNING

!

!

!

Summary of Contents for BRUSH BLAZER TBB-3002

Page 23: ...23 TBB 3002 Gen 5 Exploded View...

Page 24: ...24 TBB 0671 Complete Chassis Assembly Exploded View...

Page 25: ...25 TBB 0651 Left Track Kit Exploded View TBB 0652 Right Track Kit Exploded View...

Page 26: ...26 TBB 0657 C Shaft Drive Kit Exploded View...

Page 27: ...27 TBB 0665 Hydraulic Drive Kit Exploded View...

Page 28: ...28 TBB 0628 Complete Deck Assembly Exploded View...

Page 29: ...29 TBB 0620 Blade Shaft Flange Hub Kit Exploded View...

Page 30: ...30 TBB 0629 Blade Kit Single Shaft Exploded View TBB 0606 Blade Shaft Sheave Kit Exploded View...

Page 31: ...31 TBB 0600 Deck Hood Assembly Exploded View...

Page 32: ...32 TBB 0601 Chassis Hood Assembly Exploded View...

Page 33: ...33 TBB 0601 Chassis Hood Assembly Exploded View...

Page 34: ...34 TBB 0675 Right FRS Kit Exploded View...

Page 35: ...35 TBB 0676 Left FRS Kit Exploded View...

Page 36: ...36 TBB 0672 Hydro Tank Kit Exploded View TBB 0680 Dash Kit Briggs Stratton Exploded View...

Page 37: ...37 TBB 0674 Dash Assembly Exploded View...

Page 38: ...38 TBB 0687 Briggs Stratton 36HP Vanguard Engine Kit Exploded View...

Page 39: ...39...