25

* Mow twice, at different height settings, (high, then low),

* Remember that horsepower requirements will vary with

if grass is extra tall.

the mowing conditions such as type and height of turf

the grass blade length at any given time.)

grass, moisture content, amount of leaves, whether the

(Experts recommend not cutting off more than 1/3 of

terrain is flat or hilly, etc.

PTO MODELS

C. With the mower at high idle speed, engage the

mower

A. Perform BEFORE EACH USE the maintenance list

ENGINE DRIVEN MODELS

deck.

General Safety

levers of the mower.

A. Perform BEFORE EACH USE the maintenance list

in the next section.

deck.

B. Start the engine/blower/blade assembly.

will increase horsepower requirements.

SECTION III

B. Start mower.

B. Start mower.

engagement handle of the collection system away

OPERATING INSTRUCTIONS

Only qualified people familiar with this operator’s manual

and the mower’s operator’s manual should operate this

machine.

Operation And Tips On Mowing

in the next section.

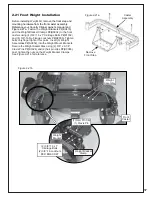

D. While seated in the operator’s seat, rotate the

from the mower. Continue to rotate the handle until it

stops in an over-center position. With the blower

engaged, you can proceed to operate the control

C. With the mower at high idle speed, engage the

mower

D. Proceed to operate the control levers of the mower.

NOTE:

If the collection system does not appear to be

collecting the grass clippings, disengage the deck

and PTO assembly, then, engage the parking brake and

turn the mower off. Check upper and lower hoses for any

clogs.To obtain the maximum effectiveness from your

collection system, the tips listed below should be

followed:

* Watch your speed- Normal conditions will allow a

speed of up to approximately 4 mph, but thick, heavy

damp conditions will require reduced ground speed.

* Mow with sharp blades- A sharp blade cuts cleaner.

* Wet grass and leaves will decrease effectiveness and

* Mow at higher cutting heights- Remove and mulch no

more than 2” of grass length with each mowing.

ENGINE DRIVEN MODELS

Disengagement Of The PTO Assembly

B. Disengage the mower deck.

A. To disengage the PTO assembly, move Bagger PTO

WARNING:

The PTO assembly blades will continue to

spin. DO NOT TOUCH the PTO assembly, pulleys, or

the belt until the tractor is turned off. DO NOT adjust the

belt tension until the mower is turned off. Refer to the

Belt Installation section of the manual.

PTO MODELS

switch to the off position.

B. (Briggs & Stratton 900 Series) To stop the engine,

throttle the engine to the stop position.

C. (6.5HP Briggs & Stratton Vanguard) To stop the

engine, move the fuel lever to the OFF position.

Unloading The Collection System

NOTE:

To determine when the collection bags are full,

follow the following steps:

A. Stop the forward movement of the mower.

D. Engage the parking brake.

F. To remove the bags from the frame, slide bags out

and turn bags over to deposit clippings.

C. Disengage the PTO assembly.

E. Once the parking brake has been engaged, then and

only then, walk behind the mower and check the

collection bags by first unhooking the rubber strap

with S-hook that secures the plastic top, then lift the

plastic hood. Load in bags should not exceed the

height of the installed bag.

G. Slide empty bags back onto the frame and secure

plastic top with the rubber strap with S-hook.

NOTE:

Do not allow collection bags to become over-

filled as potential damage may occur to your

equipment. Also, be sure to clean the hood screen as

needed.

sharpen blades while still attached to the mower.

Maintenance Checklist

wrapped around them.

MAINTENANCE

Before each use:

1. Check blades and spindles to be sure that no foreign

objects, such as wire or steel strapping bands, are

necessary to sharpen the blades, remove the blades

SECTION IV

2. Inspect blades for wear. Replace if necessary. If it is

from the spindles before sharpening. DO NOT

2017 (v1.0)

Summary of Contents for Pro 12 DFS 49621203

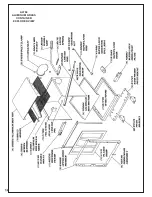

Page 18: ...18 A0794 ALUMINUM GRASS CONTAINER EXPLODED VIEW...

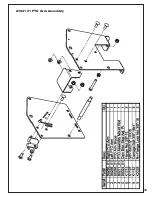

Page 19: ...19 A1841_01 PTO Arm Assembly...

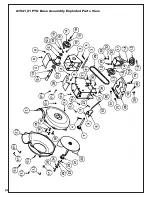

Page 20: ...20 A1941_01 PTO Base Assembly Exploded Parts View...

Page 21: ...21 A1941_01 PTO Base Assembly Exploded Parts List...

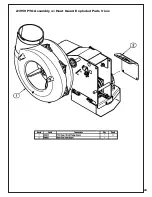

Page 22: ...22 A0623 PTO Assembly w Small Pulley Guard Exploded Parts View...

Page 23: ...23 A1950 PTO Assembly w Heat Guard Exploded Parts View...

Page 24: ...24...

Page 28: ...28...