14

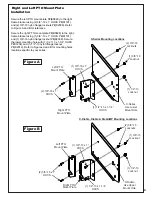

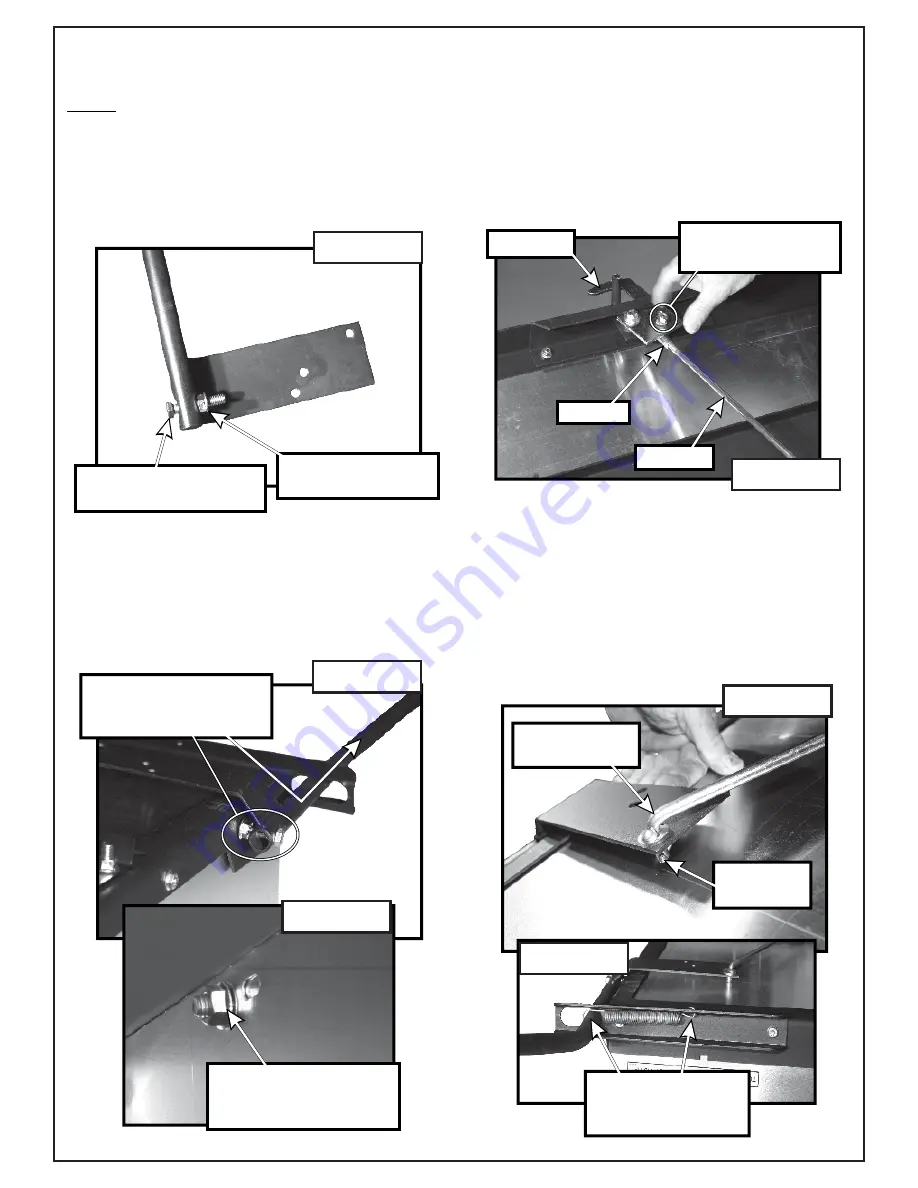

NOTE:

Before continuing the lift handle installation,

have someone assist you in turning the grass container

upside down. Insert (1) 3/8”-16 x 2” HHCS P#(K1208)

into the lift handle P#(A0614), and secure with (1) 3/8”-

16 flange nut P#(K1215). Thread the flange nut onto the

bolt upside down, as shown in Figure A.

Lift Handle Installation

Slide the lift handle through the slot on the handle mount

bracket. Insert the lift handle into the box frame as

shown in Figure B, and secure using (1) 3/8”-16 flange

nut P#(K1215) on the inside of the container as shown in

Figure C.

Fasten the ball joint P#(K1442) to the end of the latch

rod P#(A0620). Tighten the ball joint to approximately

half way down the threads on the latch rod. Attach the

ball joint to the latch hook as shown in Figure D, using

(1) 5/16”-24 hex nut P#(K1444) and (1) 5/16” lock

washer P#(K0043).

Attach the other end of the latch rod to the lift handle, as

shown in Figure E. Attach on end of the spring

P#(J0176) to the lift handle and the other end of the

spring to the handle mount bracket as shown in Figure F.

Adjust the ball joint up or down on the latch rod threads

until the latch hook closes completely. After adjusting the

latch hook, secure the latch rod to the lift handle using

(1) cotter pin P#(K0094).

Insert (1) 3/8”-16 x 2”

HHCS Into The Lift Handle

Secure With

(1) 3/8”-16 Flange Nut

Slide Lift Handle Through

Handle Mount Bracket And

Fasten To Box Frame

Use (1) 3/8”-16 Flange Nut

On The Inside Of The

Grass Container

Ball Joint

Latch Rod

Latch Hook

(1) 5/16”-24 Hex Nut

(1) 5/16” Lock Washer

Attach Latch Rod

To Lift handle

Secure With

(1) Cotter Pin

Attach Spring To

Lift Handle And To

Handle Mount Bracket

Figure C

Figure D

Figure E

Figure F

Figure A

Figure B

Summary of Contents for Pro 12 DFS 52621201

Page 16: ...16 ALUMINUM GRASS CONTAINER EXPLODED VIEW A0614 K1442 V1 131 6...

Page 22: ...22 A1841_01 PTO Arm Assembly...

Page 23: ...23 A1941_01 PTO Base Assembly Exploded Parts View...

Page 24: ...24 A1941_01 PTO Base Assembly Exploded Parts List...

Page 25: ...25 A0623 PTO Assembly w Small Pulley Guard Exploded Parts View...

Page 26: ...26...

Page 30: ...30...

Page 31: ...31 NOTES...