6

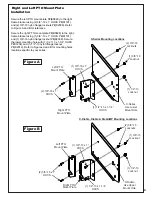

NOTE:

The mower deck PTO belt must be removed

from the electric clutch before continuing with the

installation. Refer to your mower owner’s manual for

instructions on PTO belt removal.

Preparation Of Mower

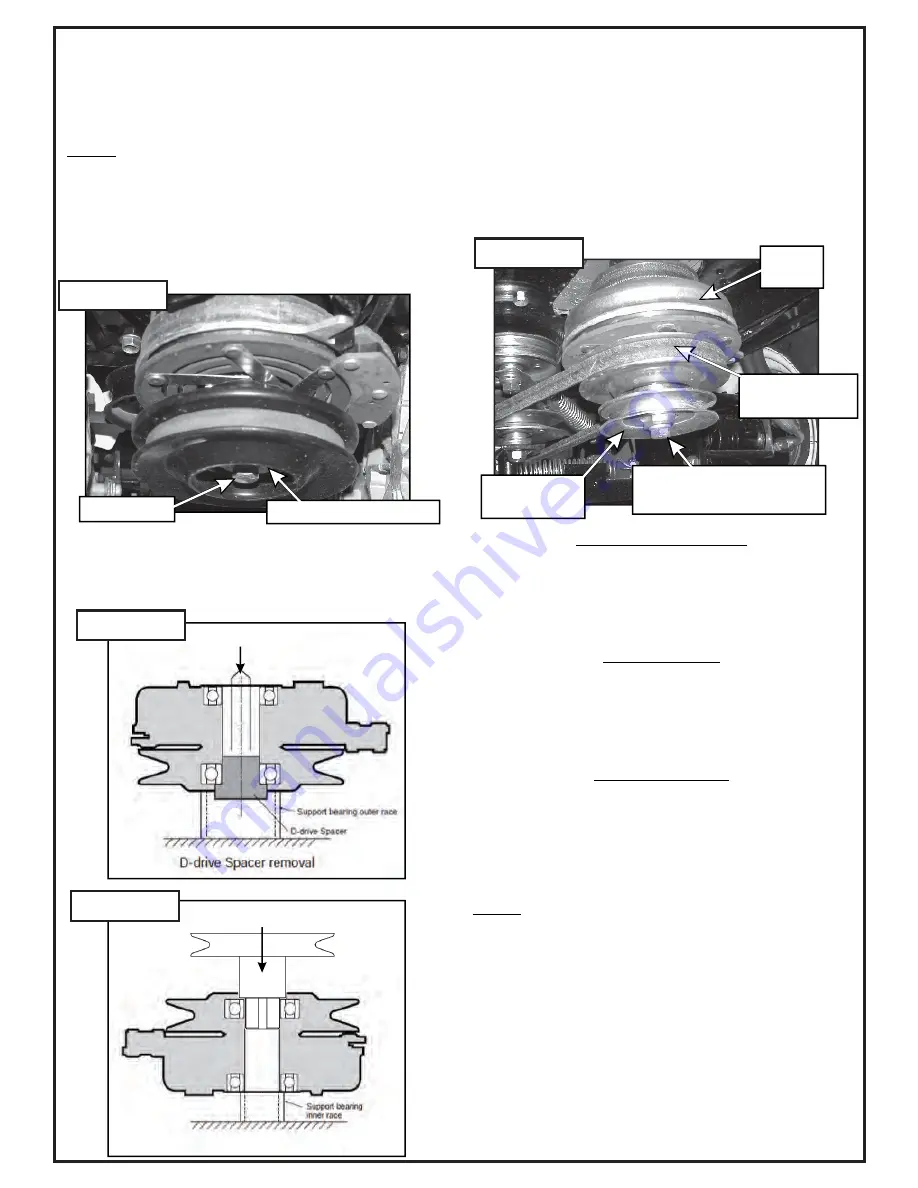

From the underside of the engine, disconnect the wiring

harness attached to the electric clutch. Remove the bolt

and electric clutch from the mower. Refer to Figure A.

Remove the D-drive spacer using an arbor press or

equivalent. On removal, adjacent bearing OUTER race

must be supported or bearing damage may occur. Refer

to Figure B.

26 HP Briggs & Stratton

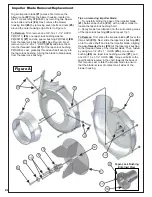

Fasten the engine pulley assembly stamped with

number 23 P#(A1175) to the electric clutch using (1)

7/16”-20 x 3-1/4” HHCS P#(K0351) and (1) 7/16” helical

spring lock washer P#(K0140). Torque the bolt to

55ft./lbs. Refer to Figure D for reference.

The engine pulley assembly must be installed using an

arbor press or equivalent. During installation, opposite

bearing inner race must be supported or bearing

damage may occur. Refer to Figure C.

Upon pressing the engine pulley to the clutch, replace

the completed assembly to the mower’s engine shaft to

fasten.

Fasten the engine pulley assembly stamped with

number 20 P#(A1798) to the electric clutch using (1)

7/16”-20 x 4-1/2” HHCS P#(K0427) and (1) 7/16” helical

spring lock washer P#(K0140). Torque the bolt to

55ft./lbs. Refer to Figure D for reference.

NOTE:

Replace the mower deck PTO belt removed at

the beginning of this section.

Kawasaki FX850

Kawasaki FX1000V

Fasten the engine pulley assembly stamped with

number 20 P#(A1798) to the electric clutch using (1)

7/16”-20 x 4” HHCS P#(K0359) and (1) 7/16” helical

spring lock washer P#(K0104). Torque the bolt to

55ft./lbs. Refer to Figure D for reference.

Section II - INSTALLATION FOR USE

PRESS

Remove Bolt

Remove D Drive Spacer

(1) 7/16”-20 Hex Bolt

(1) 7/16” Lock Washer

Electric

Clutch

Engine Pulley

Assembly

Replace Mower

Deck PTO Belt

PRESS

Engine Pulley Installation

Figure A

Figure B

Figure C

Figure D

Summary of Contents for Pro 12 DFS 52621201

Page 16: ...16 ALUMINUM GRASS CONTAINER EXPLODED VIEW A0614 K1442 V1 131 6...

Page 22: ...22 A1841_01 PTO Arm Assembly...

Page 23: ...23 A1941_01 PTO Base Assembly Exploded Parts View...

Page 24: ...24 A1941_01 PTO Base Assembly Exploded Parts List...

Page 25: ...25 A0623 PTO Assembly w Small Pulley Guard Exploded Parts View...

Page 26: ...26...

Page 30: ...30...

Page 31: ...31 NOTES...