5 of 18

ISSUED: 02-05-09 SHEET #: 202-9338-1

D

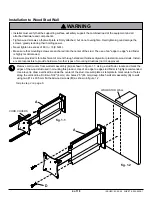

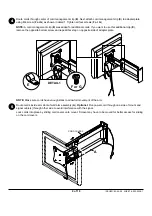

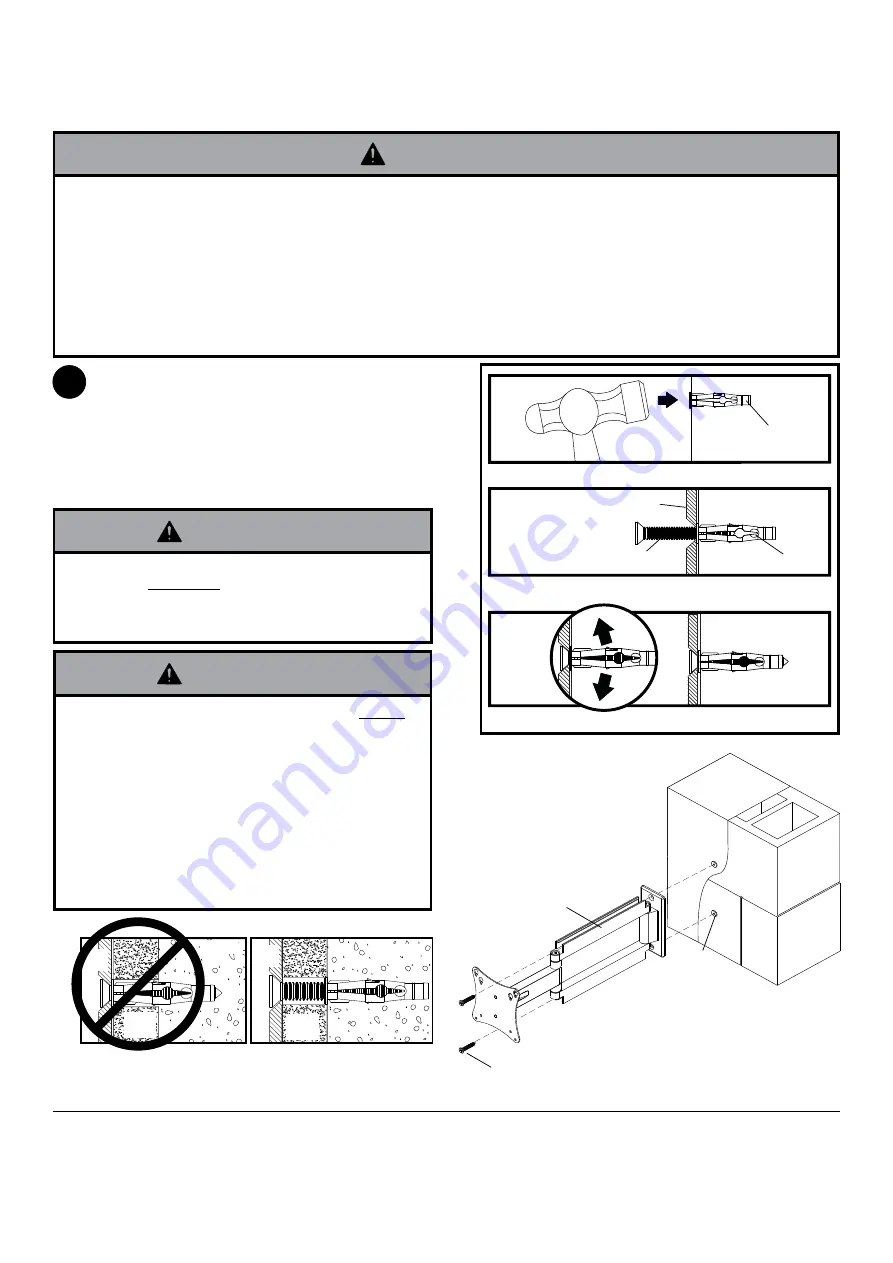

Installation to Solid Concrete and Cinder Block

Remove cord covers from wall arm assembly (

A

) as

shown in figure 1.1 on page 4. Level and use wall

plate as template to mark center of holes. Drill two

5/16" (8 mm) dia. hole to a minimum depth of 2.5"

(64 mm). Insert anchors (

C

) in holes flush with wall.

Place wall arm (

A

) over anchor and secure with

wood screw (

D

). Make sure wall arm is level, and

tighten all fasteners.

A

C

1

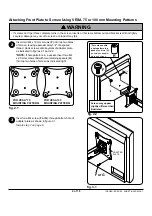

• When installing Peerless wall mounts on cinder block, verify that you have a minimum of 1-3/8" (35 mm) of actual

concrete thickness in the hole to be used for the concrete anchors. Do not drill into mortar joints! Be sure to mount

in a solid part of the block, generally 1" (25 mm) minimum from the side of the block. Cinder block must meet ASTM

C-90 specifications. It is suggested that a standard electric drill on slow setting is used to drill the hole instead of a

hammer drill to avoid breaking out the back of the hole when entering a void or cavity.

• Concrete must be 2000 psi density minimum. Lighter density concrete may not hold concrete anchor.

• Make sure that the wall will safely support four times the combined load of the equipment and all attached hardware

and components.

WARNING

• Tighten screws so that wall plate is firmly attached,

but do not overtighten. Overtightening can damage

screws, greatly reducing their holding power.

• Never tighten in excess of 80 in. • lb (9 N.M.).

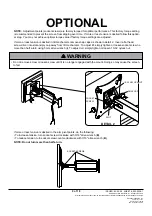

WARNING

• Always attach concrete expansion anchors directly

to load-bearing concrete.

• Never attach concrete expansion anchors to

concrete covered with plaster, drywall, or other

finishing material. If mounting to concrete surfaces

covered with a finishing surface is unavoidable,

the finishing surface must be counterbored as

shown below. Be sure concrete anchors do not

pull away from concrete when tightening screws. If

plaster/drywall is thicker than 5/8" (16 mm), custom

fasteners must be supplied by installer.

WARNING

CUT

A

W

A

Y

VIEW

INCORRECT

CORRECT

wall

plate

wall

plate

plaster/

dry wall

plaster/

dry wall

concrete

concrete

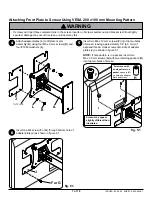

1

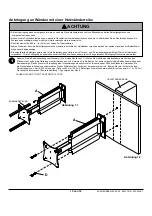

3

2

C

Drill holes and insert anchors (

C

).

Place plate (

A

) over anchors (

C

) and secure with screws (

D

).

Tighten all fasteners.

A

C

D

concrete

surface