7 of 24

ISSUED: 08-09-10 SHEET #: 061-9059-4 10-18-10

© 2010, Peerless Industries, Inc. All rights reserved.

All other brand and product names are trademarks or registered trademarks of their respective owners.

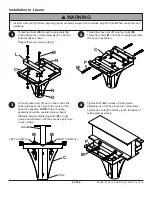

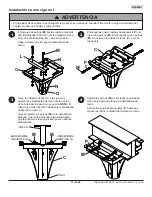

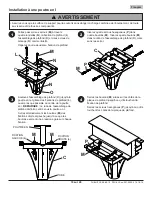

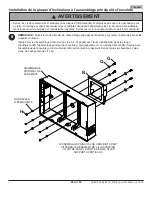

Hook tilt plate (

B

) onto bottom socket screws

threaded into adapter box (

A

) and select desired

tilt angle (0° to 20°) as shown in fi gure 10.1.

NOTE:

Be sure split lock washer (

F

) is on outside

of tilt plate as shown in detail 2.

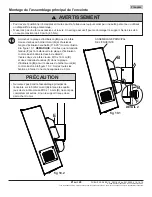

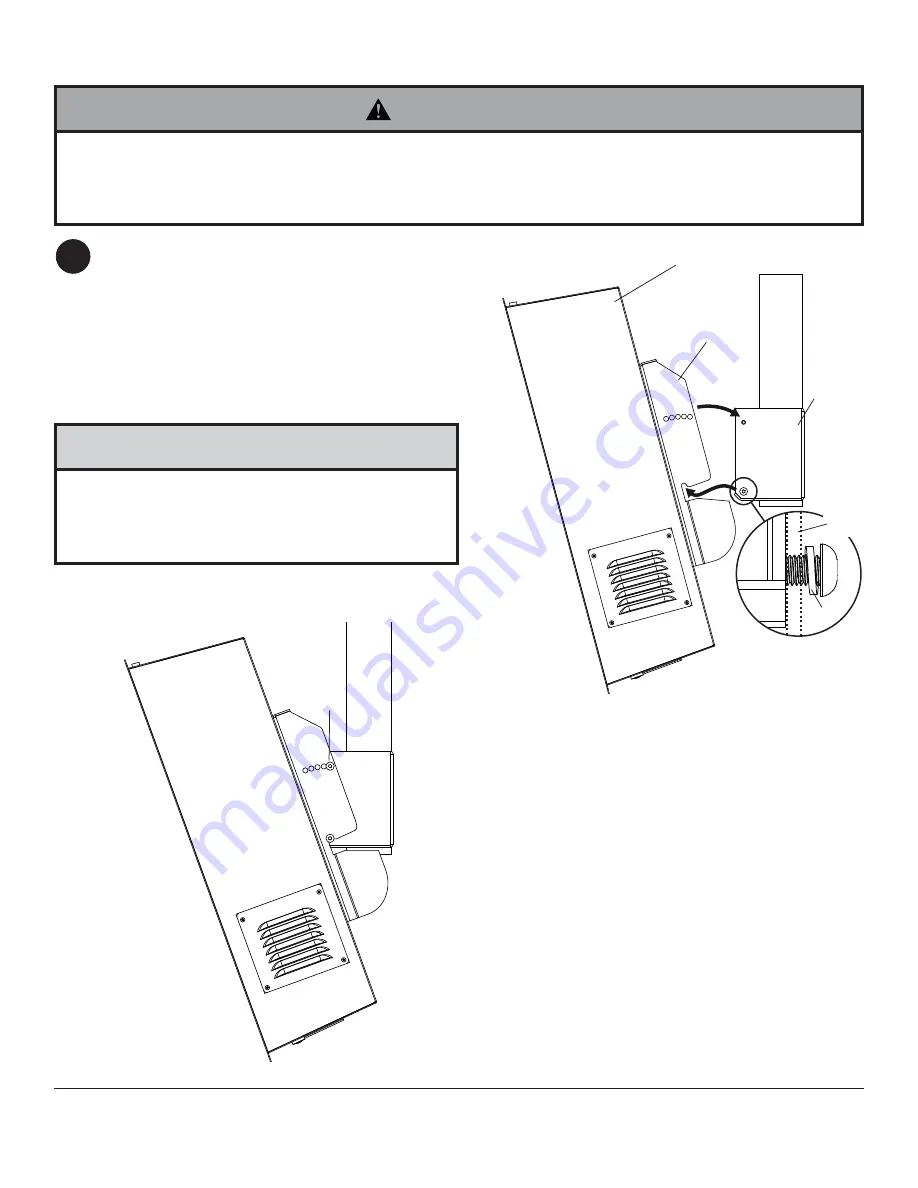

Insert two M10 x 16 mm socket screws (

E

) and

two split lock washers (

F

) through tilt plate (

B

) and

into top of adapter box (

A

) as shown in fi gure 10.2.

Tighten all fasteners using 6 mm allen wrench.

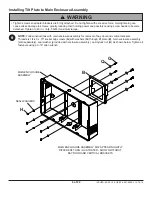

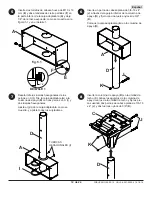

Mounting Main Enclosure Assembly

10

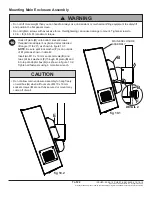

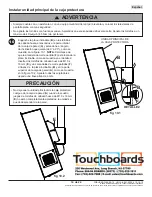

• Do not lift more weight than you can handle. Always use an assistant or mechanical lifting equipment to safely lift

and position the fl at panel screen.

• Do not tighten screws with excessive force. Overtightening can cause damage to mount. Tighten screws to

40 in. • lb (4.5 N.M.) maximum torque.

WARNING

• Do not allow main enclosure assembly to hang freely

on wall box (

A

) when all four sets of M10 x 16 mm

socket screws (

E

) are not fully secured or mount may

come off of wall.

CAUTION

fi g 10.1

fi g 10.2

B

E

MAIN ENCLOSURE

ASSEMBLY

DETAIL 2

F

A

B