ISSUED: 02-18-09 SHEET #: 090-9165-1

Visit the Peerless Web Site at www.peerlessmounts.com

For customer care call 1-800-729-0307 or 708-865-8870.

4 of 8

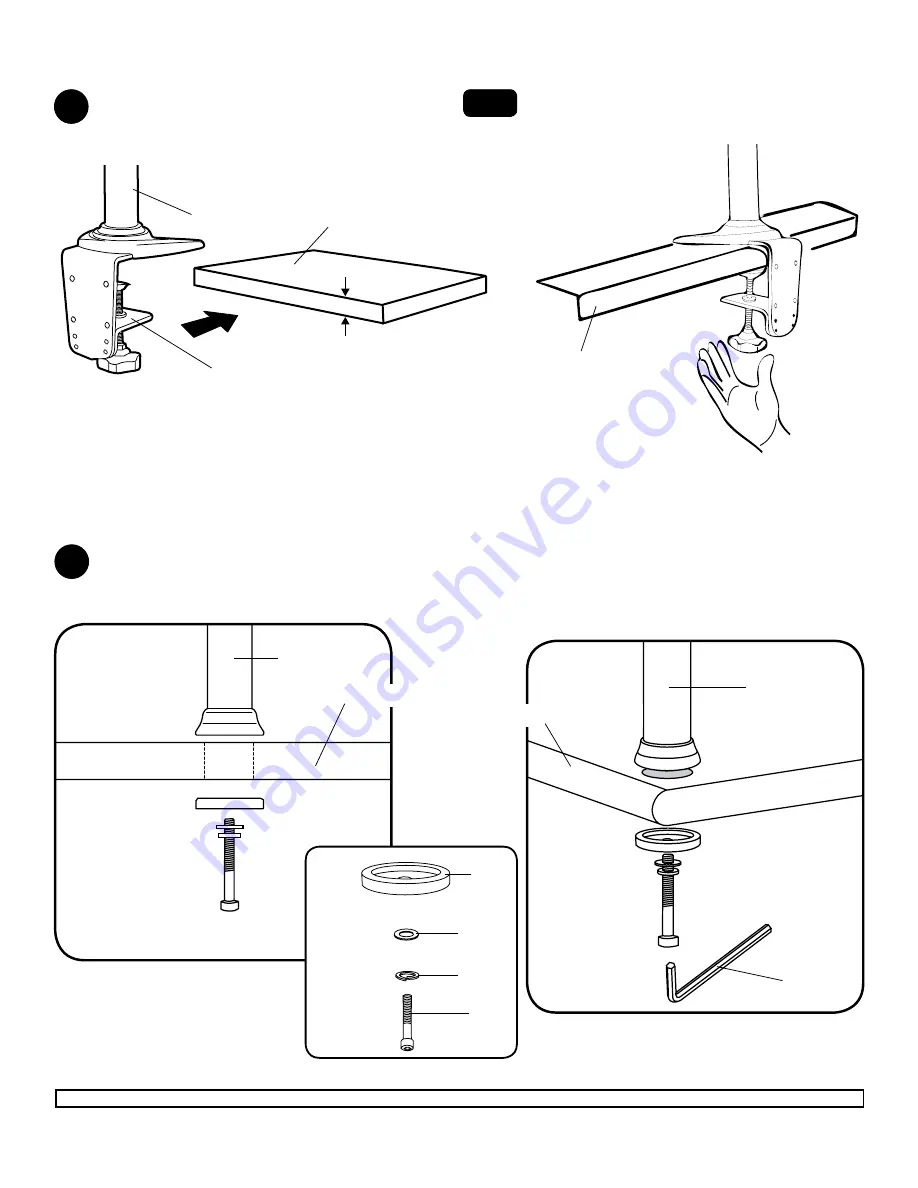

A

Pipe assembly (

A

) can be mounted to mounting

surface with a thickness of 1/3" - 3.5" (10 - 89 mm).

Insert the clamp onto mounting surface as shown

below.

Turn handle to tighten pipe assembly (

A

) to

mounting surface until firmly attached.

1/3" - 3.5"

MOUNTINg SURFACE

CLAMP

MOUNTINg SURFACE

1

Clamp Installation Method

1-1

fig. 2.2

fig. 2.1

Drill .5" (13 mm) hole into mounting surface. Place pipe assembly (

A

) onto mounting surface and secure using one

bolt (

M

), one spring washer (

N

), one flat washer (

o

), and one bottom washer (

P

) as shown in figure 2.1.

Tighten bolt (

M

) using 8 mm wrench (

Q

) as shown in figure 2.2.

NoTe:

Be sure fasteners and washers are assembled in correct order as shown in detail 1.

DeTAIL 1

2

Hole Installation Method

MOUNTINg SURFACE

MOUNTINg SURFACE

P

o

N

M

Q

A

A