ISSUED: 02-18-09 SHEET #: 090-9167-1

Visit the Peerless Web Site at www.peerlessmounts.com

For customer care call 1-800-729-0307 or 708-865-8870.

3 of 8

Parts may appear slightly different than illustrated.

Before you begin, make sure all parts shown are included with your product.

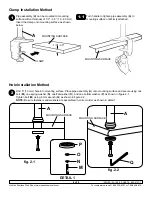

A

B

Description

LCT-A1B6C

Part #

LCT-A1B6H

Part #

A

pipe assembly

1

1

B

arm assembly

1

1

C

M4 x 10 mm screws

4

4

D

M4 x 16 mm screws

4

4

e

bar bushing

1

1

F

cable guide

2

2

G

lower pipe cap

1

1

H

upper pipe cap

1

1

J

M4 x 8 mm screws

4

4

K

4 mm allen wrench

1

1

L

2.5 mm allen wrench

1

1

M

bolt

-

1

N

spring washer

-

1

o

flat washer

-

1

P

bottom washer

-

1

Q

8 mm wrench

-

1

Parts List

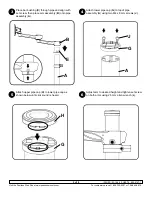

C

e

F

G

H

J

K

L

Q

M

N

o

P

D