13 of 13

ISSUED: 06-05-06 SHEET #: 202-9142-4 12-06-06

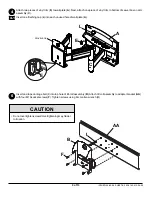

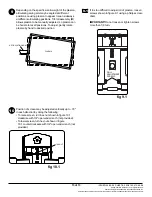

Position of screen may be adjusted vertically up to .79"

in each direction by doing the following:

• To raise screen, turn hex nut shown in figure 10.1

clockwise with 3/4" open-end wrench (not provided).

• To lower screen, turn hex nut shown in figure

10.1 counterclockwise with 3/4" open-end wrench (not

provided).

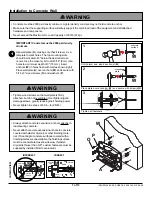

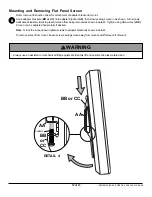

If it is too difficult to adjust roll of plasma, loosen

screws shown in figure 9.1 using a phillips screw-

driver.

IMPORTANT! Do not loosen or tighten screws

more than 1/8 turn.

Depending on the specific size & weight of the plasma,

articulating swing arm may be angled at different

positions, causing plasma to appear to lean sideways

at different articulating positions. Tilt-roll assembly (B)

allows plasma to be manually adjusted, so plasma can

be horizontal at all positions. To adjust, gently rotate

plasma by hand to desired position.

9

9-1

ARTICULATING ARM

PLASMA

10

fig 9.1

HEX NUT

fig 10.1

ROLL

ADJUSTMENT

SCREWS

©2006 Peerless Industries, Inc. All rights reserved.

Peerless is a registered trademark of Peerless Industries, Inc.

All other brand and product names are trademarks or registered trademarks of their respective owners.