8 of 16

ISSUED: 02-05-09 SHEET #: 202-9321-1

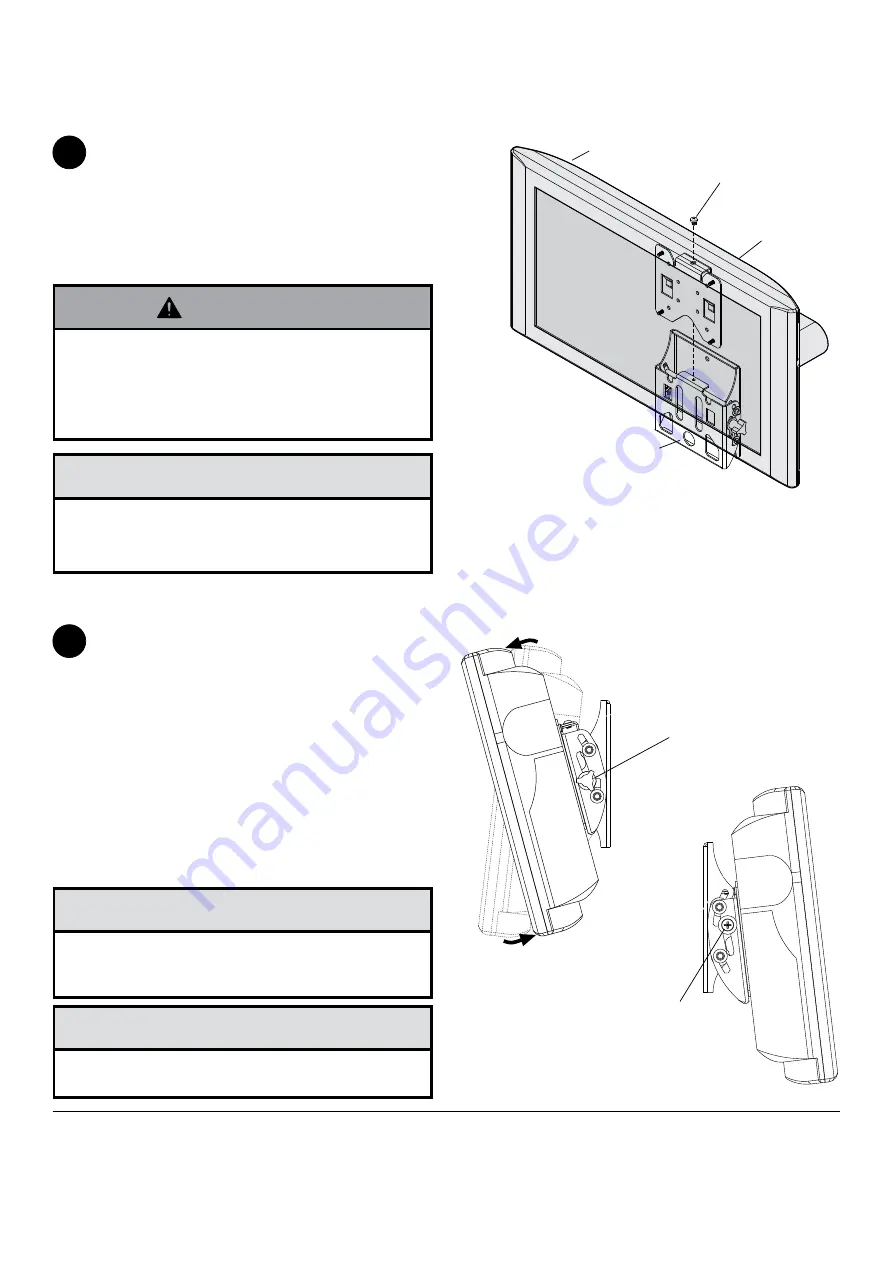

Attach screen to tilt assembly (

B

). Tighten M5 x 6 mm

screw (

J

or

N

) to lock screen to tilt assemby.

For security installation tighten M5 x 6 mm socket

pin screw (

N

) using 4 mm security driver (

O

) to lock

screen to tilt assemby.

To remove screen from mount, loosen screw (

J

or

N

)

and lift screen off of mount.

Installing and Removing Flat Panel Screen

3

A

SCREEN

• Do not tighten screws with excessive force.

Overtightening can cause damage to mount.

Tighten

screws to 20 in. • lb (2.26 N.M.) maximum torque.

CAUTION

• Do not lift more weight than you can handle. Use ad-

ditional man power or mechanical lifting equipment

to safely handle placement of the screen.

• Failure to lock hook bracket (

A

) with screw (

J

) can

cause screen to come off mount if hit accidentally.

WARNING

Adjust tension knob on right side of mount shown in

figure 4.1 to desired tension to balance your screen

size and weight.

Note:

If knob is inaccessible, remove screen from

mount, adjust tension knob to desired tension to

balance your screen size and weight, and reattach

screen to mount as stated in step 3.

Push or pull from top or bottom of screen to adjust

tilt as shown in figure 4.1. The tilt can be adjusted to

a maximum of 15° forward or 5° backward.

Note

: To lock the screen into the desired tilt

position, tighten tension screw on left side of mount

shown in figure 4.2 using phillips screw.

4

Adjusting the Tilt Angle of the Flat Panel Screen

• Be careful not to pinch fingers when pushing screen

from the bottom.

CAUTION

• Do not tighten screws with excessive force.

Overtightening can cause damage to mount.

Tighten

screws to 40 in. • lb (4.5 N.M.) maximum torque.

CAUTION

fig. 4.1

fig. 4.2

TENSION KNOB

TENSION SCREW

B

fig. 3

© 2009, Peerless Industries, Inc. All rights reserved.

All other brand and product names are trademarks or registered trademarks of their respective owners.

Peerless Industries, Inc.

3215 W. North Ave.

Melrose Park, IL 60160

www.peerlessmounts.com

J or N