REPAIR INSTRUCTIONS

TYPE AE PUMPS

MECHANICAL SEALED

Read this entire bulletin

before attempting to repair this pump. For installation

and operation refer to instruction bulletin 2880549.

Properly installed, your Peerless Pump will give you

satisfactory, dependable service. We urge that you care-

fully read these step-by-step instructions, to simplify any

problems of installation, operation or repair.

Failure to read and comply with installation and

operating instructions will void the responsibility of the

manufacturer and may also result in bodily injury as well

as property damage.

This bulletin is intended to be a permanent part of your

pump installation and should be preserved in a

convenient location for ready reference. If these

instructions should become soiled, obtain a new copy

from Peerless Pump Company include pump model

and/or serial number with your request.

Peerless Pump Company

These instructions are prepared for a pump with grease

or oil lubricated bearings and mechanical seals in the

stuffing boxes. Optional features are covered by

separate instructions sheets which are furnished when

the equipment supplied includes these features.

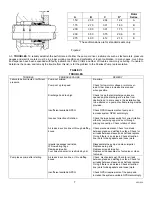

Many models have suffix letters in the model number.

These suffix letters have been intentionally omitted from

Table I. However, when ordering repair parts, provide

the complete model number including suffix letters and

the pump serial number; both are stamped on the pump

nameplate.

4851959

Rev. 11/93