WARRANTY

New equipment manufactured by Seller is warranted to

be free from defects in material and workmanship under

normal use and service for a period of one year from

date of shipment; Seller’s obligation under this warranty

being limited to repairing or replacing at its option any

part found to its satisfaction to be so defective provided

that such part is, upon request, returned to Seller’s

factory from which it was shipped, transportation

prepaid. This warranty does not cover parts damaged

by decomposition from chemical action or wear caused

by abrasive materials, not does it cover damage

resulting from misuse, accident, neglect, or from

improper operation, maintenance, installation,

modification or adjustment. This warranty does not cover

parts repaired outside the Seller’s factory without prior

written approval. Seller makes no warranty as to starting

equipment, electrical apparatus or other material not of

its manufacture, since the same are usually covered by

warranties of the respective manufacturers thereof.

Do not operate this pump at any pressure, flow rate, or

liquid temperature other than those for which the pump

was originally purchased. Do not pump any other liquid

than the one for which the pump was originally purchased

Before starting disassembly of the pump, it is

recommended that a set of spare parts as shown on

page 8 be obtained. Peerless Pump Company does not

recommend reuse of gaskets, O-rings, mechanical

seals, or ball bearings.

Shut down pump. Disconnect power to the pump driver

before starting any repairs. Refer to Bulletin No.

2880549 for the procedure to follow.

WARNING

1-1. Disengage the coupling halves. Refer to the

coupling manufacturers’ instructions.

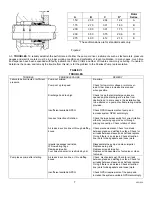

1-2. PUMP. (See Figure 1.) Disassemble pump to the

extent required as follows:

a. Remove all nuts or cap screws from the upper casing

(1B) and from the bearing caps (41 & 43). Match mark

bearing caps to lower casing (1A).

b. Loosen the gland bolt nuts.

c. Use the jack screws (not shown) on the bottom side of

the lower casing split flange to separate the upper and

lower casings. Turn the jack screws back below the split

flange surface to avoid reassembly interference.

4851959

In the event, notwithstanding the terms of this

agreement, it is determined by a court of competent

jurisdiction that an express warranty has been given by

Seller to Purchaser with respect to the head, capacity or

other like performance characteristics of said

equipment, Seller’s liability for breach of the same shall

be limited to accepting return of such equipment FCA.

plant of manufacture, refunding any amount paid thereon

by Purchaser (less depreciation at the rate of 15% per

year if Purchaser has used the equipment for more than

thirty (30) days) and canceling any balance still owing on

the equipment.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY

OTHER WARRANTIES, EXPRESSED OR IMPLIED,

AND SELLER SPECIFICALLY DISCLAIMS ANY

IMPLIED WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE.

WARNING

without the consent of Peerless Pump or its authorized

representatives. Disregard of this warning can result in

pump failure and serious personal injury or death.

SECTION I - DISASSEMBLY

d. Attach hoist to customer-furnished eye bolt in upper

casing. Use eye bolt to lift upper casing only. Eye bolt

must have ½-13 UNC external thread.

e. Place slings around the shaft near the bearing

housings and lift rotating element from lower casing

(1A). Tap lightly on the underside of the bearing

housings to separate the housings form the brackets.

f. Place rotating element in a convenient work place.

1-3. ROTATING ELEMENT. Disassemble in the

following manner:

a. Loosen set screws and remove the coupling half. Tap

from the back of the hub or use a puller. Remove

coupling key (46), and outboard deflector (40B).

b. Take out cap screws to remove bearing covers (35,

37) and the gaskets (73B). Remove inboard bearing

cover seal (47) from cover (35) only if replacement of

seal is required.

c. Remove retaining ring (18A) from outboard end of

shaft.

d. Remove housings (31 & 33), bearings (16 & 18), and

bearing housing seals (169) as units with a bearing

puller. Remove deflectors (40A).

e. Remove casing rings (7). On most pumps this may be

done before removing the coupling half.

2