NOTE

Clearances in Table I are for standard bronze or cast iron

fitted pumps. For materials with a tendency to gall, such as

stainless steel, increase clearances by .010 inch.

NOTE

For bronze impellers and rings, the rings are shrunk on the

hub according to standard fit FN-4 of ANSI B4.1.

Hardened impeller rings are installed according to ANSI

B4.1 standard fit FN-1.

c. Install new impeller rings (8) on the impeller (shrink or

press depending on material). The impeller ring ID is

factory-machined for proper fit.

NOTE

Standard pumps are furnished without impeller rings; the

wear surface is an integral part of the impeller. Impeller

wear rings maybe field-installed by machining. Refer to

note following paragraph 2-2b for standard fits to be

produced when making such repair. Replace impellers

which cannot be salvaged by such repair.

d. Replace worn shaft sleeves.

e. Straighten or replace shafts having excessive run-out

(eccentricity). See paragraph 2-1b.

3-1. ROTATING ELEMENT. (See Figure 1) Reassemble

as follows:

a. Coat the shaft (6) lightly with oil.

b. Place impeller key (32) in shaft keyway.

c. Align impeller (2) on shaft and install with an arbor

press or brass tubular sleeve and hammer. Guard against

bending shaft. When assembled, the impeller vanes must

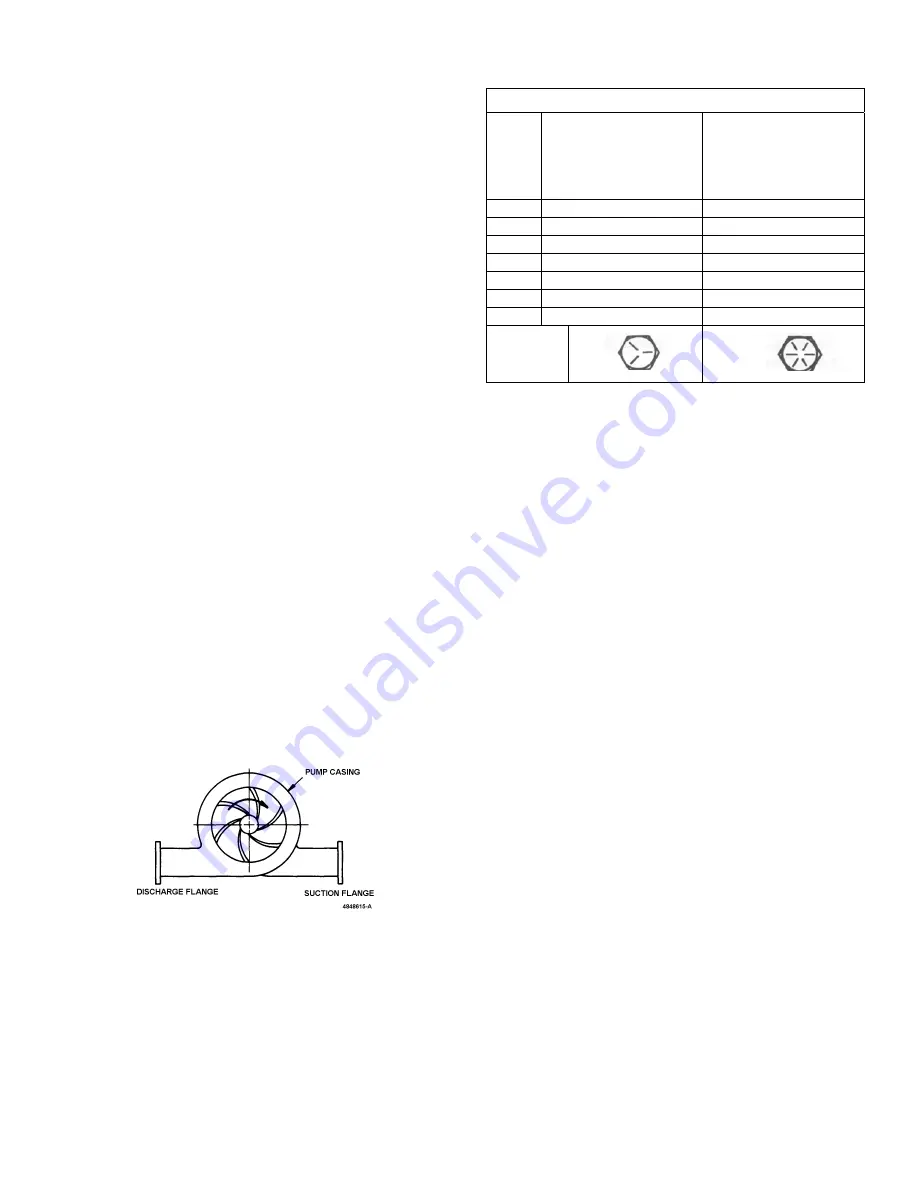

rotate in the proper direction. (See Figure 3), and impeller

hub must be centered on shaft journal.

FIGURE 3. VANE POSITION FOR PROPER ROTATION

d. Coat shaft sleeve O-rings (14B) with oil and install in

shaft sleeves (14 & 14A). Install shaft sleeve set screws in

shaft sleeves. Assemble shaft sleeves to the shaft and

hand tighten against the impeller. Do not tighten shaft

sleeve set screws.

e. Install the shaft collars (80A). Do not tighten set screws

at this time.

f. Locate casing rings (7) on impeller.

g. Lightly lubricate the O.D. of the shaft sleeves (14 &

14A), and install the mechanical seal rotating elements

(80) over the shaft sleeves.

h. Lightly lubricated the O-rings on the O.D. of the

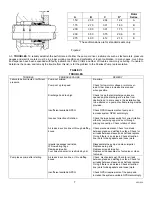

TABLE II

TORQUE VALUE (FT.-LB.)*

SIZE

INCH

MEDIUM CARBON

STEEL

SAE J429 GRADE 5

105-120,000 PSI

TENSILE

MEDIUM CARBON

ALLOY STEEL

SAE J429 GRADE 8

150,000 PSI

TENSILE

1/4 7-8

8-9

3/8 23-25

32-34

1/2 59-62

76-83

5/8 120-125

151-166

3/4 210-225

268-295

7/8 305-325

433-477

1 421-465

648-715

HEAD

SYMBOLS

*TORQUE VALUES SHOWN ARE FOR CLEAN

LUBRICATED THREADS, AND GASKETED JOINTS.

SECTION III - REASSEMBLY

mechanical seal stationary elements (65), and install

stationary elements into glands (17). Place these

assemblies over the shaft sleeves.

i. Place inboard deflectors (40A) on shaft.

j. If previously removed, install bearing housing seals

(169) into housings (31 & 33). Insert bearings (16 & 18),

into housings (31 & 33).

k. Press housing-bearing-seal assemblies on shaft to seat

bearings against shaft shoulders.

l. Install bearing retaining ring (18A) in groove against the

outboard bearing.

m. Install gaskets (73B) on bearing covers. Use factory

supplied parts or cut replacement gaskets from 1/16 inch

No. 444 Vellumoid (SAE P3415A).

EXCEPTION

: For all

models using 3306 size outboard bearing, gasket 73B is

1/32 thick.

n. Attach inboard and outboard bearing covers (35, 37). In

the assembled position, the grease drain tap must be

located at bottom in a horizontal plane.

o. Install outboard deflector (40B), and coupling key (46);

assemble coupling half on the shaft and tighten the

setscrews.

3-2. PUMP. Complete the assembly of pump as follows:

a. Use factory supplied casing gasket (73A) or use the

upper casing (1B) as a template to cut a casing gasket

(73A) from 1/64 inch Vellumoid (SAE P3313B). It is very

important that specified material and thickness be used for

casing gasket. Machined surfaces of both casings must be

perfectly clean and free from burrs and nicks.

5

5

4851959