b. Affix the new casing gasket to lower casing (1A) with

shellac.

c. Use slings around the shaft bearings to set rotating

element into lower casing. Position the casing rings (7)

and both bearing housings so that all dowel pins engage in

slots in the lower case split surface.

d. Assemble both bearing caps per match marks and

tighten the cap screws.

e. Adjust the shaft sleeves (14 & 14A) to center the

impeller in the lower casing volute, and tighten both shaft

sleeves with a spanner wrench, then tighten shaft sleeve

set screws to 130 inch-pounds torque.

f. Position shaft collars to location dimension D as shown

in Figure 2 and tighten set screws. If pump was built with

special mechanical seals, a separate sheet was furnished

showing installation details.

g. Cover the top side of the casing gasket with a mixture of

graphite and oil. Install the gland bolts (17B). Carefully

locate the upper casing on the lower, making certain the

dowel pins engage. Install cap screws and tighten, working

from the center of the casing to each end, to the torque

values in Table II. If any cap screws require replacement,

use only parts with equal or greater tensile strength. See

Table Ii. Rotate shaft by hand to check that it turns freely.

h. Evenly tighten glands (17) against stuffing box faces. Do

not tighten excessively. This can cause gland breakage.

i. Rotate shaft by hand to check that it turns freely.

j. Replace all drain plugs if removed during disassembly.

k. Re-lubricate the bearings. Refer to Table IV.

It is most important to provide proper lubrication and

keep bearings clean. Frequency of lubrication must be

determined by experience, as it depends upon bearing

size, speed, operating conditions and environment. Table

III should be used only as a guide for re-lubrication.

TABLE III

GREASING FREQUENCY

(See Table IV for amounts)

SERVICE GREASE

EACH

Normal, 8-hour day operation.

Room free of dust and damaging

atmosphere.

6 Months

Severe, 24-hour day operation.

Room with moderate dust and/or

damaging atmosphere, or outdoor

service.

1 Month

Light, approximately 10-hour week.

Room relatively free of dust and

damaging atmosphere.

1 Year

4851959

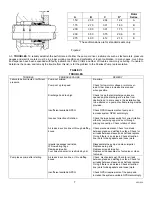

TABLE IV

AMOUNT OF GREASE FOR BALL BEARINGS

OUNCES GRAMS

BEARING

SIZE

1 28

206/305

2 56

207/306

2-1/4 63

208/307

2-1/2 70

210/308

3-1/2 100

212/310

4-1/2 128

213/311

GREASE SPECIFICATION:

Use Lithium soap base, worked penetration, meeting

NLGI Grade 2 specifications. Minimum dropping point

355 ºF., operating temperature range of –10 ºF. to 240 ºF.

Obtain grease from you local supplier.

l. Oil. (Pumps are shipped without oil in the bearing

housings.) Be sure to fill and adjust constant level oilers

before initial start of pump.

(1) Adjust dust cap to lowest possible position on base

fittings.

(2) The pipe nipple and base fitting must be level; check

with spirit level. Oiler that is not level will not provide

proper lubrication to the bearings.

(3) Fill bottle, screw it into the dust cap as far as it will

go –do not force. Allow the oil to flow into the bearing

housing. Repeat this procedure until there remains a

supply of oil in the bottle. Never fill bearing housing

through base fitting.

(4) Check the breather tube for cleanliness. The

breather tube must be used with the oil lubrication

system.

(5) The bottle on the constant level oilers is made of

plastic, and it will be damaged by oil temperature

over 170 degrees F or solvents such as alcohol. For

these conditions, use a glass bottle.

LUBRICATING INSTRUCTIONS

1. The pump is shipped without oil in the bearing housings.

2. Change first oil after operating 1000 hours or 60 days, whichever

occurs sooner.

3. Frequency of oil change thereafter is dictated by service conditions. It

is suggested, however, that oil changes occur at least every 3000 hours

of operation.

4. In order to keep the bearing housings vented, the breather tubes and

filters must be kept clean.

Lubricating Oils

Type:

High quality non-detergent straight H.V.I. mineral oil.

Weight:

Brg. Operating Range (ºF) Weight

0-150 150 SSU at 100 ºF.

150-200* 300 SSU at 100 ºF.

200-250* 500 SSU at 100 ºF.

*Maximum oil temperature in plastic oiler bottle 170 ºF.

m. Consult the driver manufacturer’s Maintenance instruct-

ions for lubricants and re-lubrication procedures for the

driver bearings

.

6