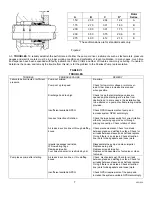

A

B

C

D*

Rotor

Series

1.50 2.38

2.94 1.94 A

1.75 2.75

3.31 1.63 B

2.00 3.00

3.31 1.75 C

2.38 3.50

3.75 2.06 D

2.75 4.00

4.12 2.19 E

*These dimensions are for standard seals only.

Figure 2

3-3.

TROUBLES.

To reliably establish the performance of either the pump or driver, instruments such as tachometers, pressure

gauges and electric meters must be in proper working condition and preferably of recent calibration. In many cases, much time

and expense have been expended with faulty instruments. Table VI lists a number of troubles commonly occurring. If unable to

determine the cause, and remedy the trouble from this list, refer the problem to the Peerless Pump representative.

TABLE VI

TROUBLES

TROUBLE PROBABLE

CAUSE

REMEDY

Failure to deliver liquid or sufficient

pressure

Pump not primed.

Pump not up to speed.

Discharge head too high.

Insufficient available NPSH.

Incorrect direction of rotation.

Air leaks in suction line or through stuffing

boxes.

Impeller passages restricted.

Worn wearing rings.

Damaged impeller.

Foot valve too small or restricted by dirt.

Re-prime.

Check for low motor voltage or motor over-

load. Other drives, increase driver speed

when possible.

Check to see that all discharge valves are

opened and the discharge line is free from

obstructions. In some cases, the installation has

to be altered or a pump of suitable rating must be

provided.

Check NPSH requirements of pump and

increase system NPSH accordingly.

Check the impeller assembly for correct rotation

either by removing upper case or through

priming connection. Check rotation of driver.

Check mechanical seal. Check for air leak

between gland and stuffing box face. Check for

air leaks between sleeve and shaft and replace

O-ring if there is an air leak. Check all suction

line joints for bad gaskets and loose joints.

Disassemble the pump and clean impeller.

Replace worn parts.

Replace or repair impeller.

Replace with adequate size foot valve or clean

foot valve.

Pump loses prime after starting

Air leaks in suction line, or thru stuffing

boxes.

Insufficient available NPSH.

Check mechanical seal. Check for air leak

between gland and stuffing box face. Check for

air leaks between sleeve and shaft and replace

O-ring if there is an air leak. Check all suction

line joints for bad gaskets and loose joints.

Check NPSH requirements of the pump and

increase the system available NPSH accordingly.

7

4851959