Peerless Pump Company

P.O. Box 7026 – Indianapolis, IN 46207-7026

Phone: (317) 925-9661 – Fax: (317) 924-7388

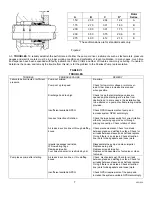

TABLE VI (Continued)

TROUBLES

TROUBLE PROBABLE

CAUSE

REMEDY

Overload on driver

Pump speed high.

Total head lower than rating

Liquid is of higher specific gravity or

viscosity than rating.

Mechanical trouble of pump or driver.

Motor voltage higher than name plate rating will

cause the motor to run faster. Either reduce motor

voltage or trim impeller diameter. On other drives,

reduce speed if possible. If speed reduction not

realized, trim impeller diameter.**

Check suction and discharge pressures and

determine the total dynamic head. If total head

lower than ratings, throttle discharge to rated total

head or, if this is not possible, reduce impeller

diameter.**

Check with Peerless distributor to determine if a

larger motor is required.

See if pump and motor turn freely. Check impeller

fit, shaft straightness and ball bearings.

Pump vibrates or is noisy

Driver unbalanced.

Misalignment

Cracked foundation.

Worn ball bearings.

Disconnect driver and operate it alone. Check

pump for large pieces of debris, such as wood,

rags, etc.

Realign pumping unit.

Replace foundation.

Replace bearings. Check lubricants for proper

grade. Check pump alignment.

**Always obtain new trim diameter from Peerless Pump Company representative.

SPARE PARTS. To keep delays to a minimum when

pump repairs are required, we suggest that the following

spare parts be stocked:

(a) One set of bearings (16) & (18), bearing seals (47) &

(169), and bearing cover gaskets (73B).

(b) One set of shaft sleeves (14) & (14A) and sleeve O-

rings (14B).

(c) One set of casing rings (7).

(d) One set of impeller rings (8).

(e) One casing gasket (73A).

(f) One set of mechanical seals (65 & 80), and gland

O-rings (17C).

For installations where downtime is critical, a complete

rotating element should be stocked.

To obtain quick and accurate service when ordering

spare parts, provide the following information:

(A) Pump size and type as noted on nameplate.

(B) Pump serial number as noted on nameplate.

(C) The name and number of the parts as shown on

the sectional drawings.

(D) Quantity required of each item.

Aid may be obtained from the Peerless Pump Company

representative or an authorized distributor for planning

an adequate supply of spare parts.

NOTICE: Materials of construction, specifications, dimensions, design features, and application information, where

shown in this bulletin, are subject to change and/or modification without notice by Peerless Pump Company at their

option.

BULLETIN NO. 4851959

8