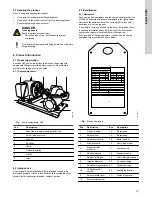

4.8 Starting up the product

4.8.1 Starting the pump

1.

Open the inlet valve completely, and close the outlet valve

completely.

2.

Switch the power supply on.

3.

Start the pump.

4.

Immediately make a visual check of the pump and inlet pipe.

5.

Allow the pump to ramp up to full speed.

6.

Slowly open the outlet valve until the operational flow is

achieved.

7.

Check the outlet pipe for leaks.

8.

Open the isolating valves for the pressure gauges.

9.

Record the pressure readings.

10. Verify that the pump performance is within the tolerance of the

pump performance curve.

4.8.1.1 Air in the system

Entrained air reduces pump total head and flow rate.

Use an eccentric reducer on the inlet pipe.

Return lines into tanks should terminate a minimum of two

pipe diameters below the low liquid level.

4.8.1.2 Checking the driver lubrication

Before running the drivers either separately or connected to the

pump:

1.

Follow the driver manufacturer instructions for lubrication

requirements.

2.

Ensure that the grease-lubricated bearings in the driver have

been properly greased with the grade of grease recommended

by the driver manufacturer.

4.8.1.3 Driver settings

Refer to the manufacturer's instructions.

4.8.1.4 Pump performance

Initial field test data becomes a valuable baseline for

future troubleshooting and maintenance. It may not be

possible to match the factory performance due to

differences in system resistance.

Once the pump is operating, verify the following:

1.

The pipe connections are tight, and no leaks are present.

2.

The following attributes match the pump nameplate:

a. operating speed

b. flow rate

c. inlet and outlet pressure

d. power input, P1.

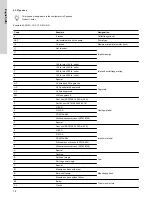

5. Storing and handling the product

5.1 Short-term storage

Standard factory packaging is suitable for protection during

shipment and during covered storage at a job site for a short period

between installation and startup. The preservatives applied at the

factory have an effective life of two to three months from the date of

shipment from the factory, depending on the severity of the

environment in which the equipment is exposed. For international

destinations, this will vary depending on the seaworthiness of

export boxing.

5.1.1 Controlled storage

Storage facilities should be maintained at an even temperature with

a relative humidity lower than 50%, and little or no dust. Inspect

and recoat the equipment periodically with water displacement rust

inhibitor, vapor phase inhibitor, or rust preventive coating.The

equipment must be inspected weekly to ensure that all

preservatives are intact, and internals are protected.

5.1.2 Uncontrolled storage

For uncontrolled storage periods of three months or less, inspect

the equipment weekly to ensure preservatives are intact and

internal parts are protected.

Preparing the product for uncontrolled storage

•

Periodically inspect and recoat the equipment with rust and

vapor phase corrosion inhibitors.

•

Seal all pipe threads and flanged pipe covers with tape. Place

an adequate amount of desiccant near the center of the pump.

•

If the pump is assembled, place and securely fasten

additional desiccant in the outlet of the pump.

•

Cover the equipment with black polyethylene or equivalent,

with a minimum thickness of 0.006 in (0.15 mm).

•

Provide a ventilation hole approximately the size of a small

coin.

•

Provide protection from direct exposure to the environment.

•

If applicable, connect space heaters on equipment such

as motors, engines or controls.

5.1.3 Short-term storage

•

The pump and equipment, as shipped, have adequate

protection for short-term storage for up to three months.

•

If the product is not to be installed and operated immediately

after receiving it, store it in a clean, dry area at a moderate

ambient temperature.

•

For packed-type pumps, the packing glands may be left on the

pump shaft and securely fastened in position. All exposed

machined surfaces should be thoroughly coated with a film of

rust preventative material.

•

For packed-type pumps, the stuffing box packing must be

removed and stored in a sealed plastic bag. Seal the end of the

stuffing box with rolled vapor phase inhibitor paper and seal

with weatherproof tape.

•

Rotate the shaft by hand periodically, at least monthly, to coat

the bearing with a lubricant to retard oxidation and corrosion.

•

Make sure the pump cannot roll or fall over.

•

Follow the motor manufacturer's storage recommendations

where applicable.

5.1.4 Long-term storage

•

Long-term storage protection provided by the factory does not

extend the warranty in any manner.

•

The warranty is valid only if the equipment is properly handled

and stored.

•

In case of storage up to six months or longer, the pump must

be protected against heat and moisture as described in the

previous sections.

•

Periodically, at least monthly, manually rotate the shaft to coat

the bearing with a lubricant to retard oxidation and corrosion.

•

Ensure that the pump cannot roll or fall over.

•

Follow the motor manufacturer's storage recommendations

where applicable.

•

Inspect the pump before putting it into operation. Make sure

that the impeller can rotate freely. Pay special attention to the

condition of the shaft seals or the packing and O-rings.

5.1.5 Accessories storage

Store accessories according to the manufacturer's instructions.

14

English (US)