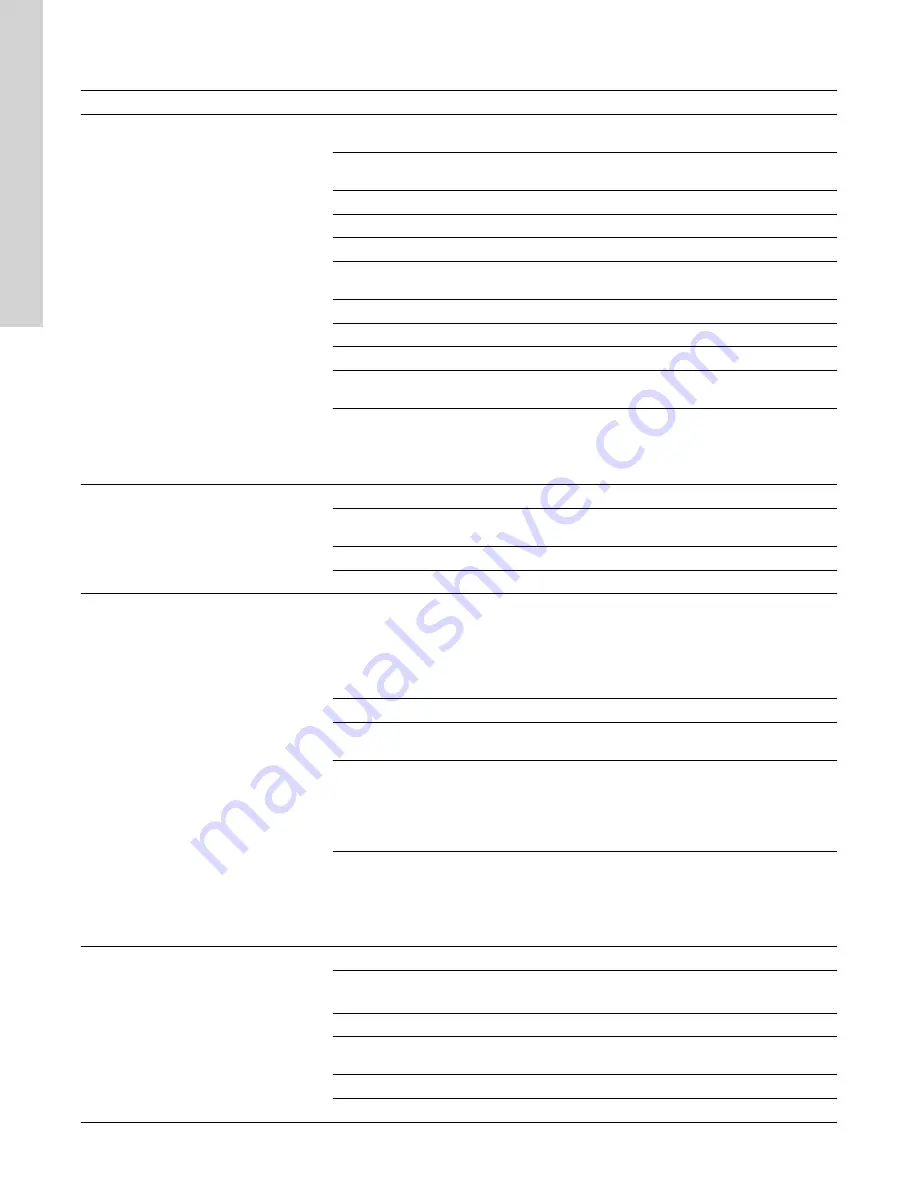

10. Fault finding the product

Fault

Cause

Remedy

The outlet pressure is too low.

The speed of rotation is too low.

Reestablish the correct speed and direction

of rotation.

The system pressure is lower than

anticipated.

Check the system curve.

There is air or gas in the pumped liquid.

Remove the air from the pumped liquid.

The wear rings are worn.

Replace the wear rings.

The impeller is damaged.

Repair or replace the impeller.

The impeller diameter is too small.

Replace the impeller with one of the correct

diameter.

The direction of rotation is wrong.

Interchange two wires in the power supply.

The pump has lost its prime.

Re-prime the pump.

There is insufficient NPSH.

Restore required NPSH.

Passages are restricted.

Clean the impeller and pump housing

passages.

Joints or the stuffing box are leaking.

•

Tighten the joints or the stuffing box

gland.

•

Replace the shaft sleeve.

•

Replace the gaskets.

The inlet pressure is insufficient.

The inlet line is drawing air.

Tighten the connections.

The suction lift is too high, or there is

insufficient NPSH.

Reduce the suction lift or restore the required

NPSH.

Air or gas is trapped in the pumped liquid.

Remove the trapped air or gas from liquid.

The strainer is clogged.

Clean the strainer.

The noise level has increased.

Poor alignment of the pump. The inlet and

outlet pipe clamps are loose.

•

Reestablish proper alignment of the

pump and the motor.

•

Support the inlet and outlet pipes.

•

Make sure the vibration dampers, flexible

pipes, and conduit connectors are

installed correctly.

The foundation is cracked.

Repair the foundation.

The ball bearings are worn.

Replace the worn bearings, and renew the

lubrication.

The motor is unbalanced.

•

Disconnect the motor, and operate it

alone.

•

Remove large pieces of debris, such as

wood or rags, from the pump.

•

Clean out the pump, if necessary.

Hydraulic resonance.

•

Alter the resonant pipes.

•

Change the pump speed.

•

Insert a pulsation damper on the pump

or the pipes.

•

Insert a flow straightener.

Insufficient flow.

The pump is not primed.

Prime the pump.

The system pressure exceeds the shut-off

pressure.

•

Increase the liquid level on the inlet side.

•

Open the isolating valve in the inlet pipe.

The speed of rotation is too low.

Reestablish the correct speed of rotation.

The suction lift is too high, or there is

insufficient NPSH.

Reduce the suction lift or restore the required

NPSH.

The strainer or the impeller is clogged.

Clean the strainer and the impeller passages.

Wrong direction of rotation.

Reestablish the correct direction of rotation.

26

English (US)