2.2 Inspecting the product

The product must be inspected after transport and before

installation.

To complete the inspection, follow the steps below:

1.

Check the product for transport damage. Contact the

transporter immediately in case of damage.

2.

Check that the delivered products correspond to the order.

3.

Check the positions and sizes of fittings.

4.

Retighten various connections, as they may have become

loose during transport.

2.3 Transporting the product

The pump has been prepared for shipment at the factory so as to

minimize potential damage due to handling and transport.

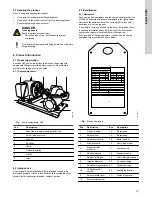

WARNING

Crushing hazard

Death or serious personal injury

‐

Make sure all persons stand clear of the load and the

lifting equipment while product is lifted, lowered,

loaded and unloaded. Do not allow anyone to stand

on, under, or near the load.

Do not subject the pump to excessive g-forces during

handling or transport.

2.4 Scope of delivery

A typical shipment will include:

•

one skid with the fire pump and the driver mounted on the base

plate

•

one skid with the controller and accessories, if any

•

installation and operating instructions.

Refer to the original order in case of questions about shipping, for

example, special arrangements with third-party vendors for shipping

and storage.

3. Installing the product

3.1 Factory support

For Engineered to Order (ETO) products, Peerless recommends

that you invite a Peerless service engineer to supervise the

installation and startup. This is to ensure a proper installation.

Peerless recommends that you review the instructions

provided with the pump.

3.2 Location

Install the product in a location that meets the following

requirements:

3.2.1 Minimum space

Always allow sufficient accessibility space for maintenance and

inspection. Provide a clearance of 24 inches (610 mm) with ample

head room for use of overhead lifting equipment strong enough to

lift the product.

3.2.2 Seismic analysis

When the pump is located in a seismically active area or in certain

critical installations, ensure that the pumps, supports, and

accessories are earthquake-resistant. The design specifications for

earthquake resistance vary depending on the geographical area

and the class of the equipment. The class of the

equipment depends on defining how critical is the survival of the

equipment, the characteristics of the structure's response to

accelerations, and the foundation supporting the pump.

If a seismic analysis is required, please refer to the

governing bodies recommended for grouting and

foundation requirements.

The customer must supply complete specifications for earthquake-

resistance requirements including seismic criteria, acceleration,

magnitudes, frequency spectrum, location and direction relative

to the pump and qualification procedure.

3.3 Mechanical installation

3.3.1 Recommendation for pump foundation

All rotating equipment generates vibrations when turning at high

speeds. Proper installation and anchorage of the pumps and

installation accessories are critical to limit vibrations and achieve

reliable installation. To ensure acceptable vibration levels in the

field, all parts of the system must be sufficiently stiff and firmly

anchored to minimize vibrations:

This applies for pumps above 13 hp (10 kW).

•

The foundation and concrete should be of adequate strength to

support the weight of the pump including accessories, the

weight of the liquid passing through the pump, and the forces

generated by the pump.

•

The mass of the concrete foundation should be a minimum of

three to five times the mass of the supported equipment and

should have sufficient rigidity to withstand the axial, transverse,

and torsional loadings generated by these machines.

•

The foundation should be 5.9 in (15 cm) wider than the base

plate for pumps up to 469 hp (350 kW) and 9.8 in (25 cm) wider

for larger pumps.

•

The concrete used in the foundation should have a minimum

tensile strength of 362 lb

f

/in

2

(250 N/cm

2

).

•

Always use a non-shrink epoxy grout to fasten the pump base

plate to the foundation.

3.3.2 Pump foundation

Large pumps will be mounted on a steel base anchored to

two concrete pillars.

Install the pump permanently on a firm, raised concrete foundation

of sufficient size to dampen any vibration and prevent any deflection

or shaft misalignment. The foundation may float on springs or be a

raised part of the floor.

Proceed like this:

1.

Pour the foundation without interruption to 0.75- 1.5 in (20-40

mm) below the final pump level. Leave the top of the

foundation rough. Then clean and wet it down.

2.

Scour and groove the top surface of the foundation before the

concrete sets to provide a suitable bonding surface for the

grout.

3.

Place anchor bolts in pipe sleeves for positioning allowance.

4.

Allow enough bolt length for grout, base flange, nuts, and

washers.

5.

Allow the foundation to cure several days before proceeding to

install the pump.

7

English (US)