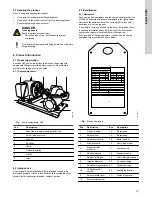

3.4 Installation preparation

3.4.1 Engine preparation

The following installation requirements help to ensure safe and

efficient operation of a pumping unit driven by a diesel engine:

1.

Ensure that the operator is familiar with the installation and

service manual supplied with the engine.

2.

Ventilate the area around the engine to keep the ambient

temperature as low as possible. With 60 °F (15.6 °C) as a data

point, every Δ 10 °F (Δ 6 °C) rise in temperature reduces the

horsepower of the engine by approximately 1%.

3.

Provide adequate air for efficient combustion.

4.

Provide the engine with an efficient exhaust system so that the

combustion gasses discharge with a minimum of back

pressure.

5.

Ensure that the fuel system is of adequate capacity and meets

codes and regulations.

6.

Provide ample space to access the engine for maintenance.

7.

Provide correct rotation of the pump. Engine rotation is

determined at the factory, and no change to engine rotation can

be made in the field.

3.5 Mechanical installation

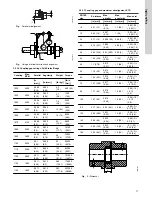

3.5.1 Pipes and connections

3.5.1.1 Inlet pipe

The inlet pipe must be installed in a manner that minimizes

pressure loss and permits sufficient liquid flow into the pump during

starting and operation.

At no point must the diameter of the inlet pipe be smaller

than that of the pump inlet port.

Observe the following precautions when installing the inlet pipe:

•

Run the inlet pipe as direct as possible, and ideally, make sure

the length is at least ten times the pipe diameter. A short inlet

pipe can be the same diameter as the inlet port. A long inlet

pipe must be one or two sizes larger than the inlet port,

depending on the length, and with a reducer between the pipe

and the inlet port.

•

Use an eccentric reducer, with the tapered side down.

•

If possible, run a horizontal inlet line along an even gradient.

We recommend a gradual upward slope to the pump operating

in suction lift conditions, and a gradual downward slope

operating in positive inlet pressure conditions.

•

Avoid any high points, such as pipe loops, as this may create

air pockets and throttle the system or cause erratic pumping.

•

Install a gate valve in the inlet line to be able to isolate the

pump during shutdown and maintenance, and to facilitate

pump removal. Where two or more pumps are connected to the

same inlet pipe, install two gate valves to be able to isolate

each pump from the pipe.

Always install isolation valves in positions that prevent air

pockets.

Do not use globe valves, particularly when NPSH is a

critical operating factor.

•

During pumping operation, the valves on the inlet line must

always be fully open.

•

Install properly sized pressure gauges in the tapped holes on

the pump inlet and outlet flanges or pipes

Pressure gauges will enable the operator to monitor the

pump performance and determine whether the pump

conforms to the parameters of the performance curve

If cavitation, vapor binding, or other unstable operating

situations occur, the pressure gauges will indicate with

wide fluctuation in the inlet and outlet pressures.

3.5.1.2 Vibration dampers

To prevent the transmission of vibrations to foundations and

surrounding structures, isolate the pump and foundation from

connected structures by means of vibration dampers. The selection

of the correct vibration damper requires the following data:

•

forces transmitted through the damper

•

motor speed(s)

•

required dampening in %.

The selection of a vibration damper differs from installation to

installation. In certain cases, a wrong damper may increase the

vibration level. Peerless recommends that the vibration dampers be

sized by the supplier. If you install the pump on a foundation with

vibration dampers, always fit expansion joints on the pump flanges.

Install expansion joints on the pump flanges to prevent the

pump from "hanging" in the flanges.

3.5.1.3 Inlet pipe

The inlet pipe must be installed in a manner that minimizes

pressure loss and permits sufficient liquid flow into the pump during

starting and operation.

At no point must the diameter of the inlet pipe be smaller

than that of the pump inlet port.

Observe the following precautions when installing the inlet pipe:

•

Run the inlet pipe as direct as possible, and ideally, make sure

the length is at least ten times the pipe diameter. A short inlet

pipe can be the same diameter as the inlet port. A long inlet

pipe must be one or two sizes larger than the inlet port,

depending on the length, and with a reducer between the pipe

and the inlet port.

•

Use an eccentric reducer, with the tapered side down.

•

If possible, run a horizontal inlet line along an even gradient.

We recommend a gradual upward slope to the pump operating

in suction lift conditions, and a gradual downward slope

operating in positive inlet pressure conditions.

•

Avoid any high points, such as pipe loops, as this may create

air pockets and throttle the system or cause erratic pumping.

•

Install a gate valve in the inlet line to be able to isolate the

pump during shutdown and maintenance, and to facilitate

pump removal. Where two or more pumps are connected to the

same inlet pipe, install two gate valves to be able to isolate

each pump from the pipe.

Always install isolation valves in positions that prevent air

pockets.

Do not use globe valves, particularly when NPSH is a

critical operating factor.

•

During pumping operation, the valves on the inlet line must

always be fully open.

•

Install properly sized pressure gauges in the tapped holes on

the pump inlet and outlet flanges or pipes

9

English (US)