TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 19 -

Recommended grease:

Texaco Regal Multifak All purpose EP2 (or equivalent)

4.3

BEARINGS - GENERAL

These instructions do not supersede any information issued by the bearing manufacturers, to whom

application should be made for more comprehensive literature.

Care and maintenance of bearings is a matter of ensuring that they are:

a. Correctly lubricated at intervals.

b. Removed, cleaned and refitted with care.

c. Tools used and work areas should be clean.

To remove a bearing, use correctly suited withdrawal equipment.

If other means are not available, a

hammer and soft metal drift may be used to tap evenly around the circumference of the inner ring.

CAUTION: Damage can be caused by exerting force against the outer ring of a ball bearing.

Ball bearings should not be dismantled.

Clean bearings thoroughly with an approved fluid.

Dry the bearings with dry compressed air. Do not spin a clean dry bearing. All the cleaning fluid must be

removed from the bearing since it might damage the lubricating properties of the grease.

Inspect the bearing for wear, fractures, cracks, corrosion or other damage which may necessitate bearing

replacement.

Work approximately 1 ounce of grease into both sides of bearing immediately after drying and inspecting, to

prevent corrosion.

Check that the bearing, shaft and housing are clean and undamaged.

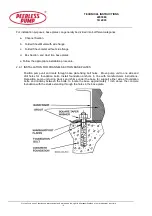

When fitting the bearing on the shaft, the use of a soft drift and hammer should be avoided if possible. The

drift could shed flakes of metal into the bearing. If a lock nut is used to "push-home" the bearing then a

special hook or "C" spanner must be used to turn it. A drift and hammer applied to one slot would cause

damage to the nut and introduce flakes of metal into the bearing. The tab washer should not be in place

during this procedure since there is a risk of shearing off the inner tab. The nut should be removed when

the bearing is fully pushed home then the tab washer placed in position and the nut refitted.

In general soaking bearings in a hot oil bath prior to fitting to the shaft is recommended.

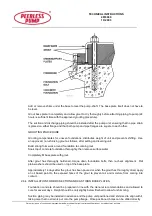

After assembly and when the bearing housings are in position, the bearing housing cavity incorporating the

grease nipple should be fully charged with the recommended grease leaving the cavity on the other side of

the bearing free of grease.

Summary of Contents for HYF

Page 2: ......