TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 21 -

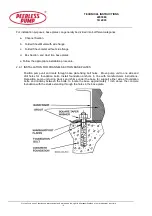

FINAL RE ASSEMBLY

The last packing ring should never protrude beyond the stuffing box face thus allowing the gland

follower to 'start' in the stuffing box. If this is not the case, then dismantle and check that the correct

number of rings have been used and that they have seated correctly.

Bring the gland follower up squarely against the last packing ring and finger tighten the securing nuts

evenly.

Turn the shaft to ensure that no binding is taking place.

Pressurize the stuffing box, ensuring their is no trapped air. The gland should start to leak heavily

almost immediately. If it does not stop the pump immediately and investigate.

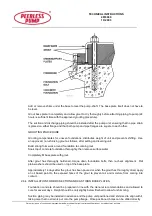

GLAND FOLLOWER ADJUSTMENT

After the pump has been running for 10 minutes at full pressure, adjust the follower nuts by one sixth

of a turn every 10 minutes until there is a small leakage only. This leakage is essential to ensure

packing is lubricated.

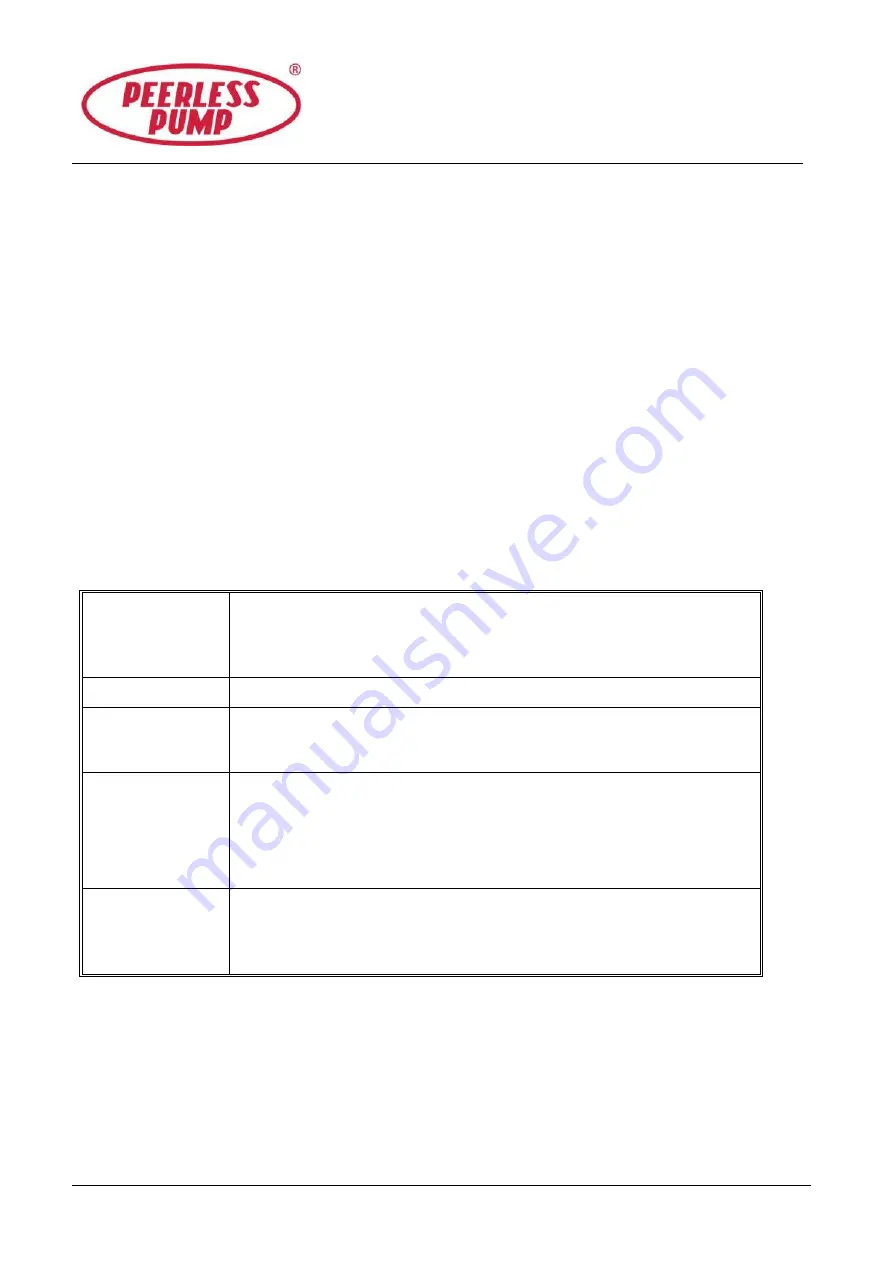

TABLE 4 ROUTINE MAINTENANCE CHART

Every Week

Visually check for leaks.

Check for vibration.

Hand test bearing housing for any sign of temperature rise.

Adjust gland as necessary to maintain slight leakage.

Every Month

Check bearing temperature with a thermometer.

Every 3 Months

Check running hours and consult re-lubrication interval chart.

Check grease lubricated bearings for saponification - i.e. signs of any

deposits, oil separation and undue hardening and softening of grease.

Every 6 Months

Check running hours and consult re-lubrication interval chart.

Check soft packed gland packing, where fitted, and replace if necessary.

Check shaft or shaft sleeve for scoring.

Check alignment of pump and motor.

Check holding down bolts for tightness.

Check coupling for wear.

Every Year

Check rotating element for wear.

Check wear ring clearances.

Clean and re-grease bearings.

Check running hours and consult re-lubrication interval chart.

Summary of Contents for HYF

Page 2: ......