TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 5 -

(2)

When lifting the unit ensure that all lifting equipment has a safe working load rating, suitable for the

operation.

Only perform lifting operations using suitably trained personnel, and in line with

instructions contained in this manual.

(3)

Persons working on the unit should always wear suitable protective clothing and footwear. Loose,

frayed or baggy clothing and light footwear can be extremely dangerous. Clothing impregnated

with oil or similar can constitute a health hazard through prolonged contact with the skin and may

also create a fire risk. Wear protective goggles and gloves when handling battery acid.

(4)

Liquids used with some pump units are harmful if taken internally or come into contact with

unprotected skin or eyes. In the event of an accident, obtain qualified medical assistance

immediately.

(5)

Always ensure that all guards supplied are correctly installed following any maintenance operation.

(6)

Ensure that the pump unit is not run outside its operational limits. This can put the unit under

excessive loads and cause breakdown.

(7)

Before starting any repairs disconnect power to the pump driver and place a conspicuous notice is

displayed warning that the unit is under repair.

If a major overhaul is being carried out it is

advisable to have a qualified electrician temporarily disconnect the unit.

1.4.2.2

PUMP HAZARDS

(1)

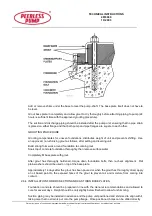

Ensure that the pump has no air in the suction line and casing. The pump rotating components

rely on the liquid being pumped for cooling and lubrication. A failure to prime could result in pump

failure.

(2)

Pump operation with insufficient lubrication to the bearings could result in overheating and seizure,

with potentially catastrophic results.

(3)

Where soft packed sealing is used it is essential that a small leakage is present. Over tightening

of the gland will result in damage to the packing, scoring of the shaft or sleeves and bearing

seizure.

(4)

Ensure that all pressure has been released before working on the unit.

(5)

Always check that the drive shafts are correctly aligned following installation. Failure to do so

could result in reduced life or a possible failure of the coupling, or bearings. (see Section 2.7).

1.4.2.3

HAZARDS RELATED TO ENGINE DRIVEN PUMP UNITS

(1)

When working with gaseous fuels, ensure that the area is well ventilated and avoid open flames,

smoking, sparks etc. A Carbon Dioxide fire extinguisher should be kept close at hand.

(2)

Parts of the package, in particular, the exhaust system and engine surfaces can become very hot

during and after operation and can cause severe burns.

(3)

Beware of the danger of scalding when removing cooling system pressure caps and hoses,

Summary of Contents for HYF

Page 2: ......