TECHNICAL INSTRUCTIONS

4853989

10/ 2003

Our policy is one of continuous improvement and we reserve the right to alter specifications of our products at any time.

- 6 -

or draining engine oil. Allow the system to cool first, then remove caps slowly.

(4)

Rectify all water, oil or fuel leaks immediately and clean up any spillage.

(5)

Before carrying out any work on the pump unit confirm that the fuel and electrical supplies to the

engine are isolated correctly, and that there is no danger that it can be started. A conspicuous

notice should be placed on the unit warning others that the unit is under repair.

1.4.2.4

PUMP UNITS FITTED WITH ELECTRONIC COMPONENTS

CAUTION

Damage can occur to the internal components when electric welding or high voltage "Megger"

tests are carried out. Electronic components should always be disconnected before carrying

out any work of this kind.

2.

INSTALLATION

2.1

RECEIVING PUMP

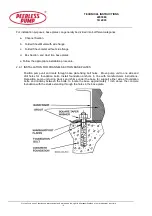

On receipt of pump, a visual check should be made to determine if any damage has occurred in transit.

Typical points to look for, are:

a. Broken or cracked equipment e.g. base plate, motor, pump feet and flanges.

b. Bent shafts.

c. Damaged motor end bells, bent eyebolts or damaged boxes.

d. Missing items.

Loose parts are often wrapped individually and/or fastened to the equipment. If any damage or losses have

occurred notify the transit company immediately and PEERLESS PUMP COMPANY.

When unloading pump units, only lift using the lifting eyes on the base plate or support frame. DO NOT

USE THE LIFTING POINTS ON THE PUMP OR MOTOR

Pump and motor shafts are in alignment when shipped, however the alignment must be re-checked before

use.

2.2

TEMPORARY STORAGE

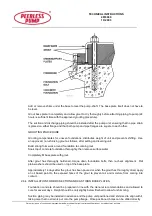

If the pump is not to be installed immediately it should be stored in a clean, dry area, with protection from

moisture, dust, dirt and foreign bodies. In particular, the following action should be taken:

a. Ensure the bearings are packed with the recommended grease, to prevent moisture from

entering around the shaft.

b. Remove the glands, packing and lantern rings from the stuffing box, where soft packed sealing is

used.

c. Check that the pump suction and discharge ports are covered to prevent foreign objects entering.

d. If, for a short period only, the pump has to be stored outside it should be covered to protect it

from the effects of the weather.

e. Every 6 weeks, rotate the pump shaft to prevent bearing pitting.

Summary of Contents for HYF

Page 2: ......